Hybrid biased radial magnetic suspension bearing

A magnetic levitation bearing, offset type technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as abnormal shutdown, major accidents, and damaged machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

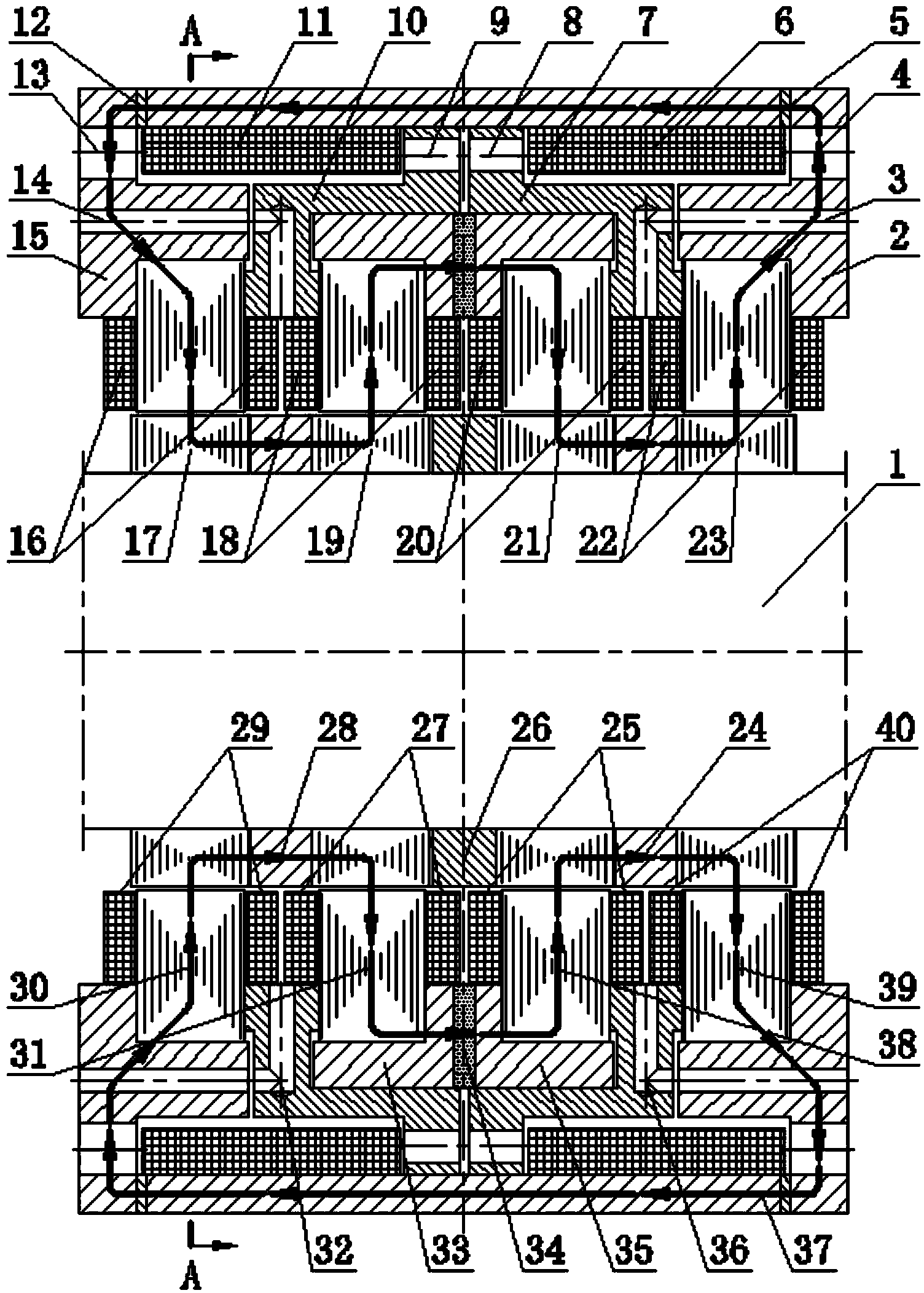

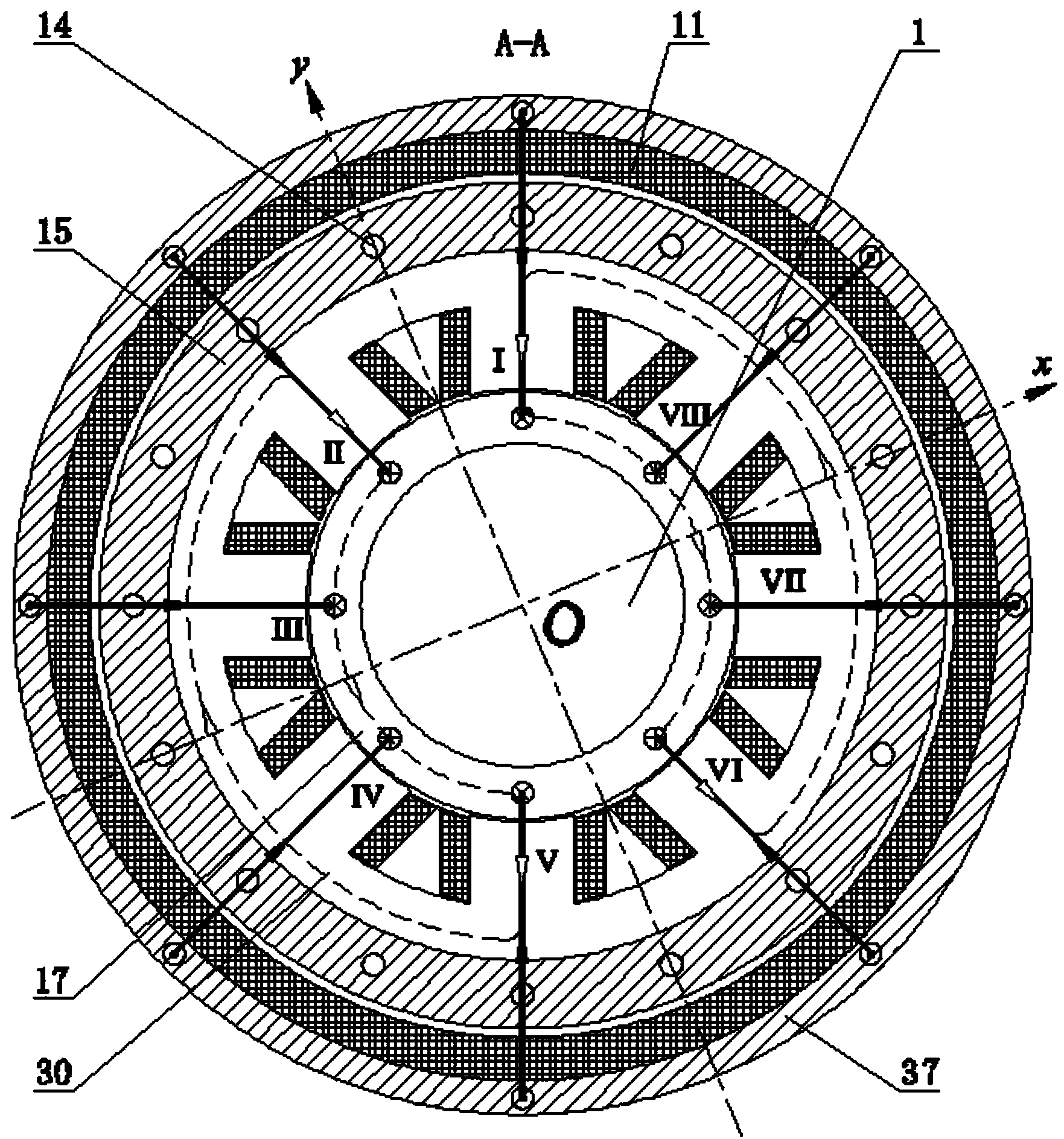

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] The hybrid offset radial magnetic suspension bearing of the present invention includes two parts: a rotor assembly and a stator assembly. Specifically, the rotor assembly includes: main shaft, 4 sets of rotor annular magnetically conductive laminations, 2 rotor annular magnetically conductive spacers and 1 rotor annular nonmagnetically conductive spacer. The stator assembly includes: ring-shaped permanent magnets, 2 sets of stator inner magnetic sleeves, 4 sets of stator pole laminations (the number of magnetic poles in each set of stator pole laminations is 4n, n is a positive integer, n is taken as 2 in Figure 1) , 4 sets of control coils (the number of each set of control coils is 4n), 4 sets of insulating square sleeves (the number of each set of insulating square sleeves is 4n), 2 stator non-magnetic sheaths, 2 stator magnetic cover plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com