Composite plastic pipe

A technology for plastic pipes and inner walls of pipes, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as large expansion coefficient, easy deformation, and low strength, and achieve high-temperature pressure-bearing performance, enhanced strength and Effect of stiffness, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

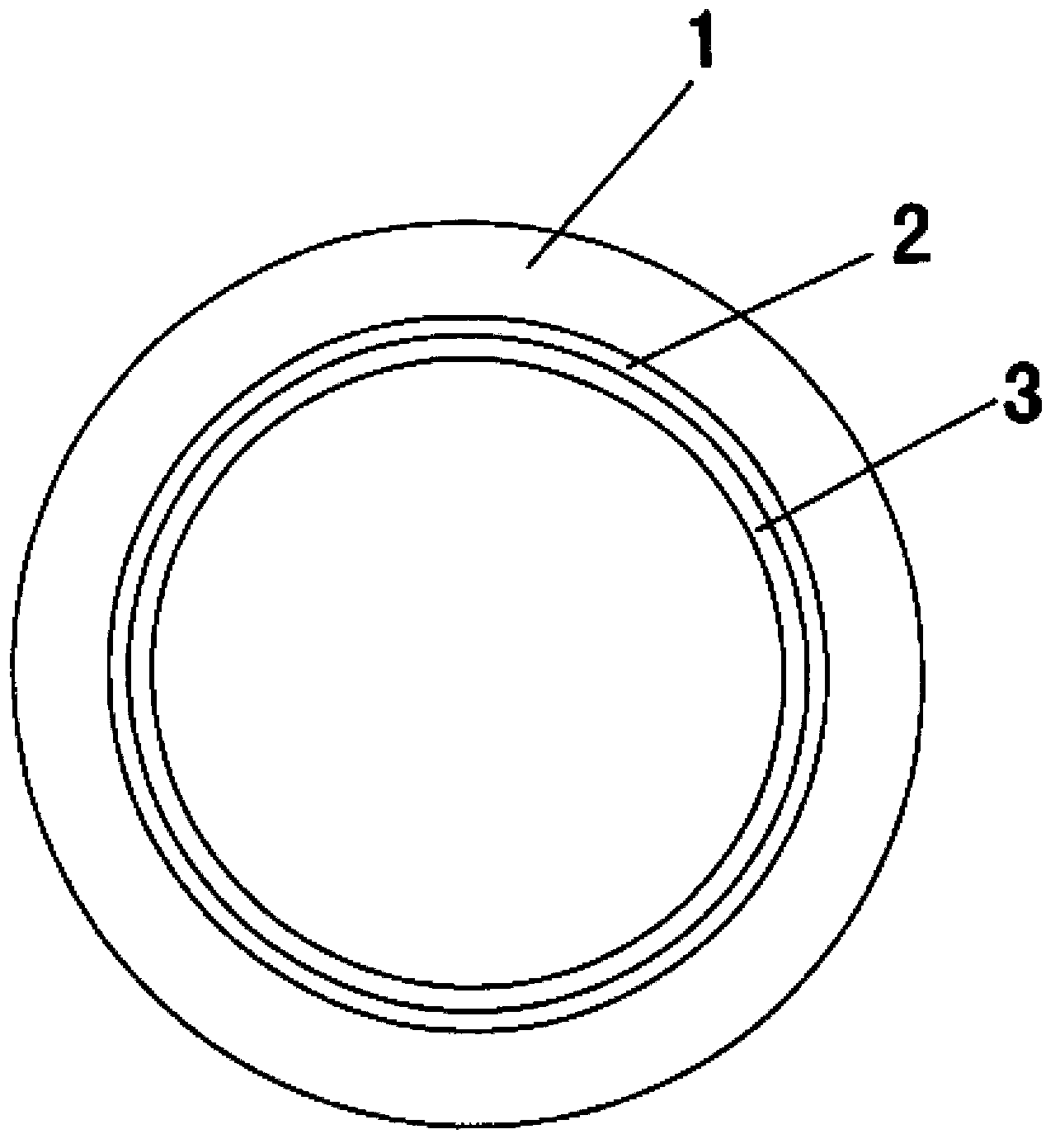

[0007] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0008] Such as figure 1 In the composite plastic pipe shown, the outer layer is a PP-R pipe, and the inner wall of the PP-R pipe is provided with a winding layer, and the winding layer is a high-strength wire wound in the PP-R pipe.

[0009] Inspired by the above-mentioned ideal embodiment according to the present invention, through the above-mentioned description content, relevant workers can make various changes and modifications within the scope of not departing from the technical idea of the present invention. The technical scope of the present invention is not limited to the content in the specification, but must be determined according to the scope of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap