Pin inspection go/no go gauge

A technology of pass and stop gauge and inspection, which can be used in measuring devices, instruments, and mechanical devices, etc., and can solve problems such as difficult detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

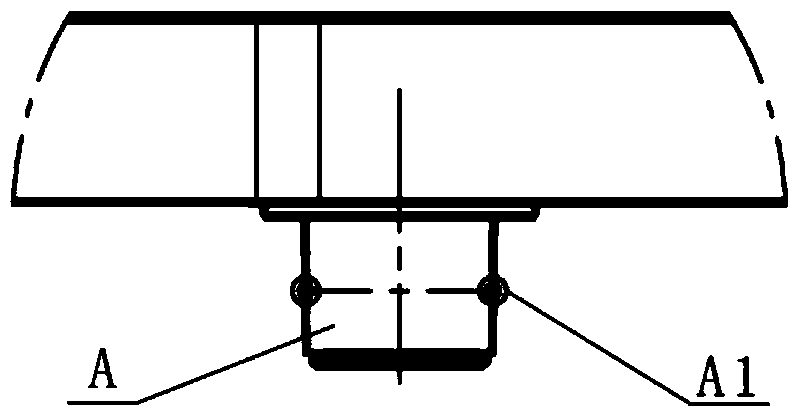

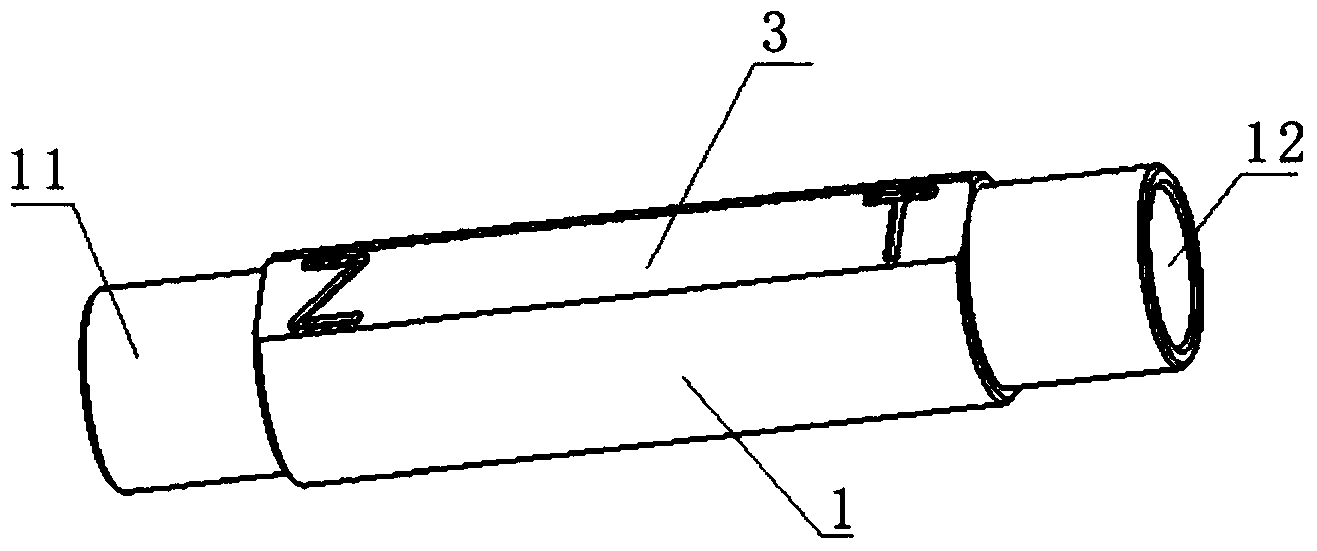

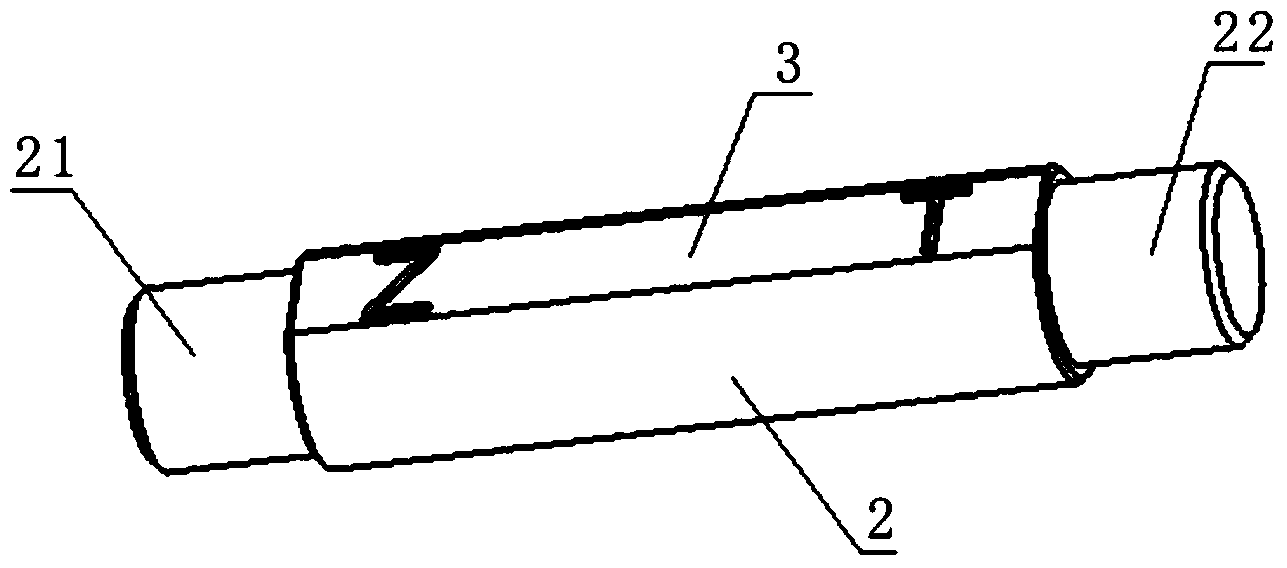

[0026] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] Such as image 3 As shown, the pin check through stop gauge 1 includes a handle 3 and a pin check end 11 and a check pin through end 12 respectively arranged at both ends of the handle 3. The pin check end 11 and the check pin through end 12 are open structures, The open structure is a sheet-like structure with holes in the middle.

[0028] In order to facilitate the use and manufacture, the sheet structure with the middle opening is a circular ring structure. Of course, it can also be made into other shapes such as hexagons, quadrilaterals, etc., with only the middle opening.

[0029] The thickness of the sheet-like structure with the middle opening is 3-10 mm. Preferably, the thickness of the sheet-like structure with the middle opening is 5 mm.

[0030] Such as Image 6 As shown, according to the requirements of the drawing, the size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com