System and method for magnetometer calibration and compensation

A magnetometer, a technology for calibrating parameters, applied in the size/direction of the magnetic field, electric magnetometer, measuring magnetic variables, etc., and can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

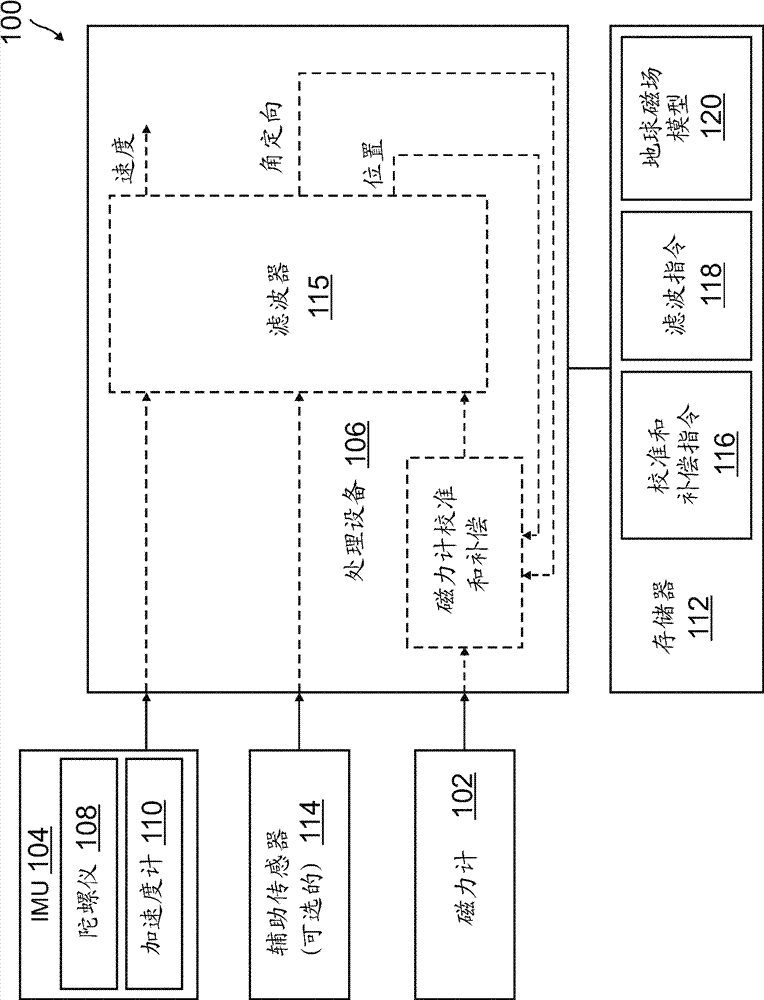

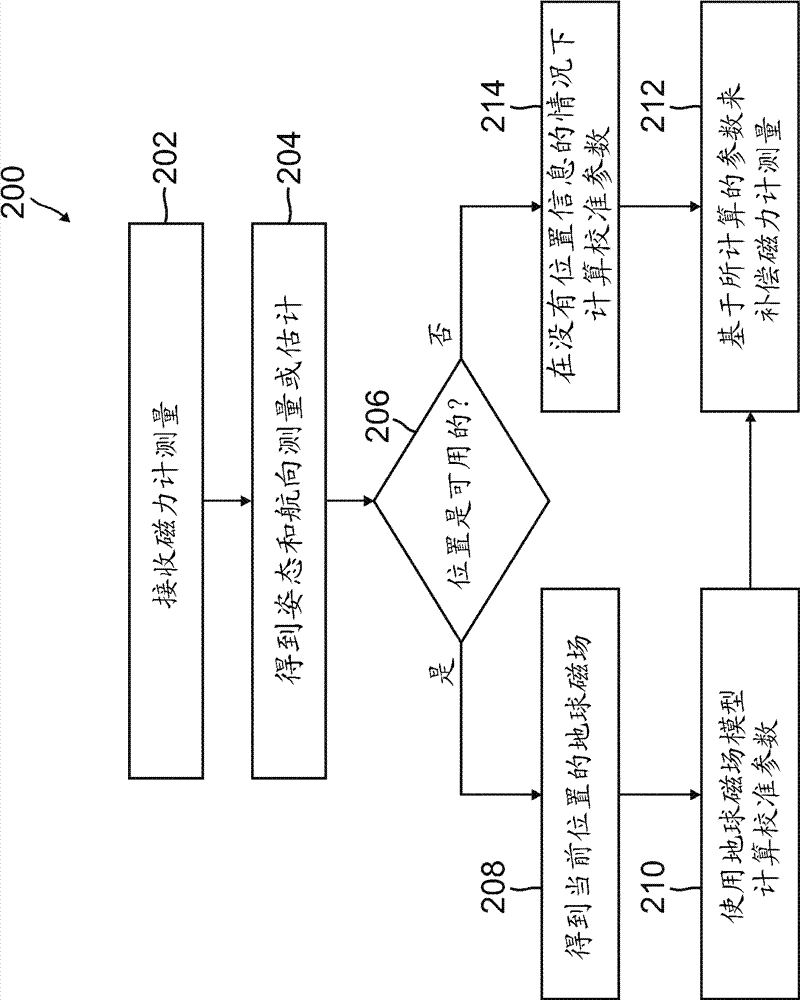

[0110] Example 1 includes a system comprising: an inertial measurement unit including one or more gyroscopes configured to measure angular velocity about respective ones of three independent axes, and configured to measure angular velocity along three independent axes one or more accelerometers of the specific force in the corresponding axis; a magnetometer configured to measure the strength of the local magnetic field along each of the three independent axes; and a processing device coupled to the inertial measurement unit and the magnetic force the processing device is configured to calculate motion state data of the system based on measurements received from the magnetometer and the inertial measurement unit; wherein the processing device is further configured to calculate a magnetometer measurement calibration parameter using a first technique when the position data is unavailable, And when position data is available, magnetometer measurement calibration parameters are calc...

example 2

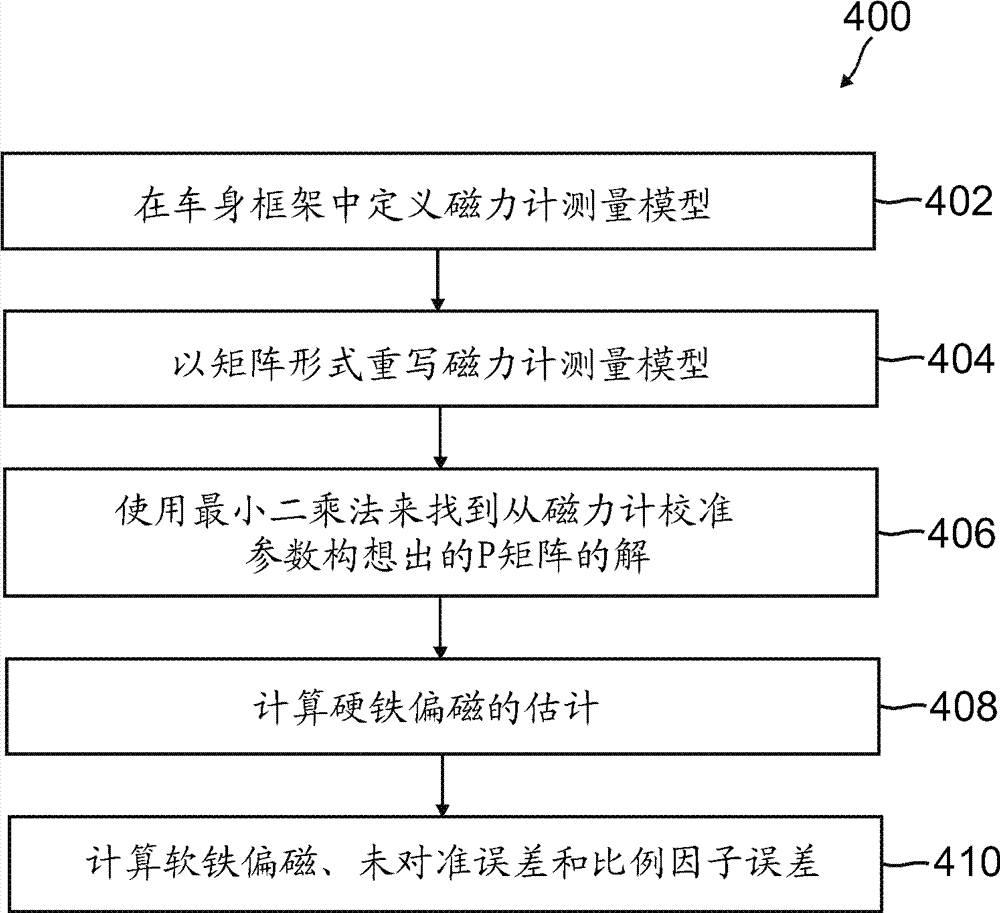

[0111] Example 2 includes the system of example 1, wherein to calculate the magnetometer measurement calibration parameters when the position data is unavailable, the processing device is configured to: calculate the hard iron bias vector from a matrix factorization of a matrix containing entries based on the magnetometer measurements ; and calculating at least one of a soft iron bias matrix, a scale factor error matrix, and a misalignment error matrix using the magnetometer measurements and the hard iron bias vector.

example 3

[0112] Example 3 includes the system of example 1, wherein to calculate the magnetometer measurement calibration parameters when the location data is available, the processing device is configured to: determine a column of a matrix containing estimated magnetic field values derived from an Earth Magnetic Field Map (EMFM) based on the location data If the matrix has a full column, calculate all the magnetometer measurement calibration parameters of the magnetometer measurement model; and if the matrix does not have a full column, calculate a subset of the magnetometer measurement calibration parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com