System and method for detecting reliability of converter valve cooling control device

A technology for cooling control and converter valve, applied in the field of converter valve cooling, can solve the problems such as the measurement accuracy of triple sensor is out of tolerance, the reliability of the refusal and malfunction control device is reduced, and the response speed of the control hardware is slow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

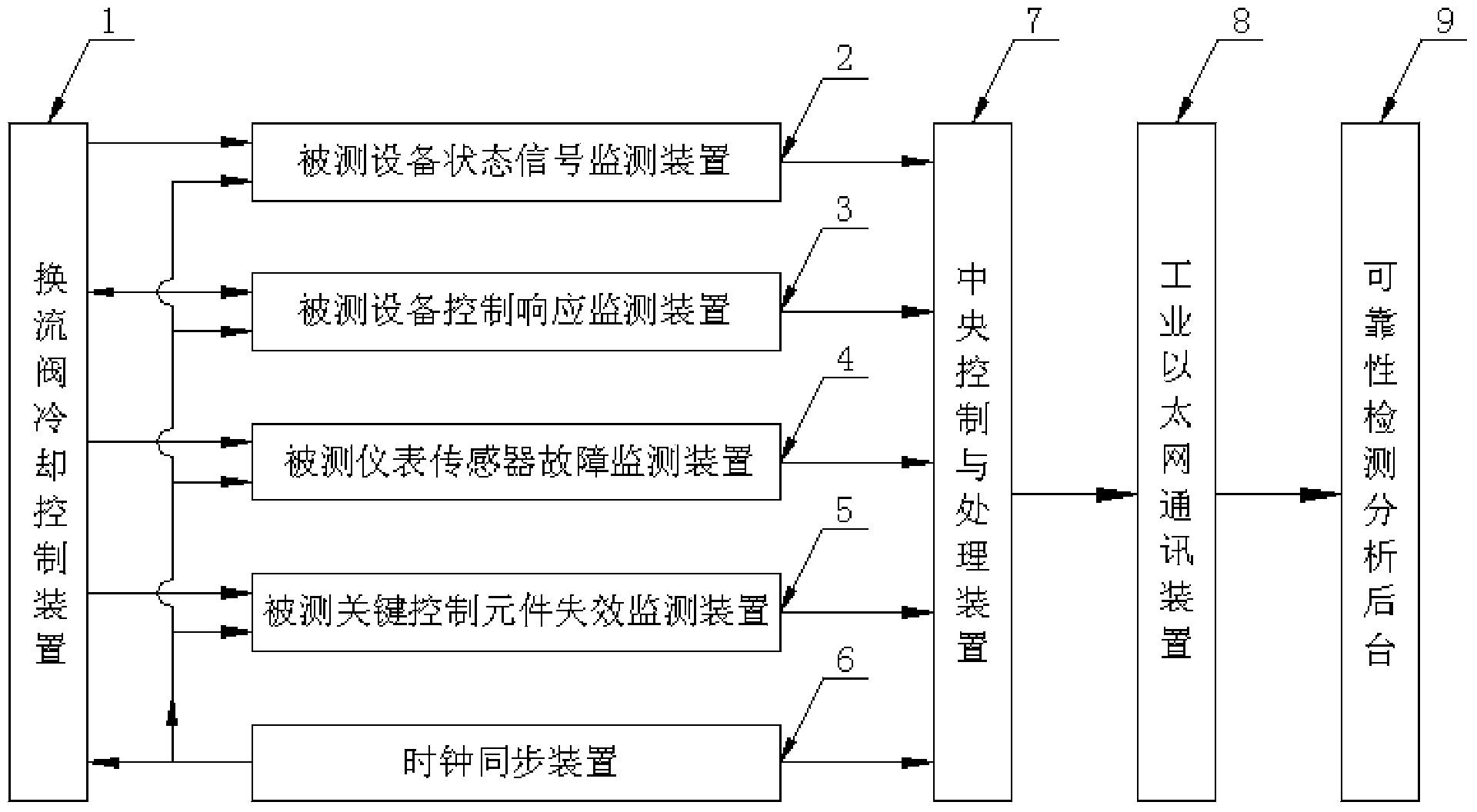

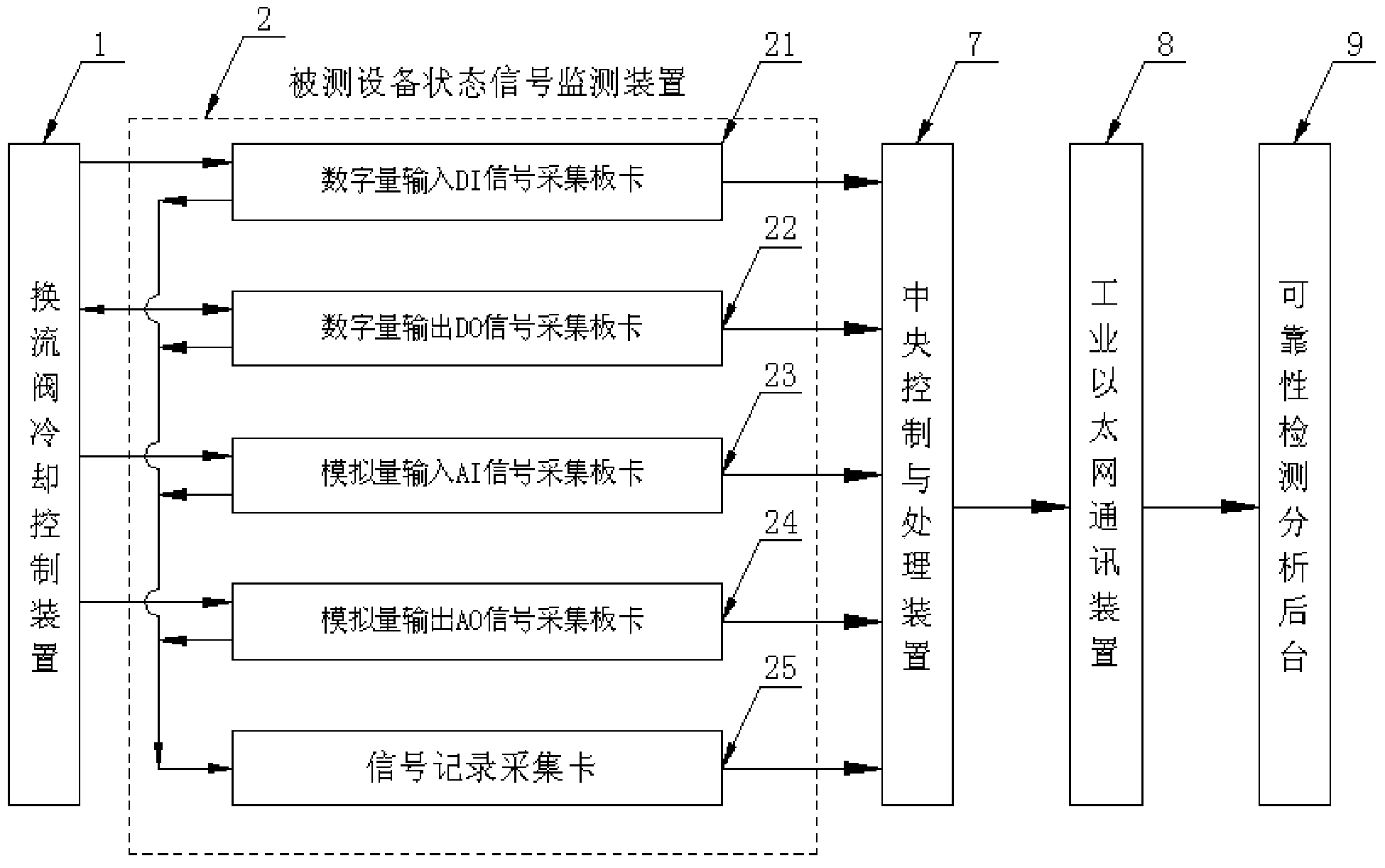

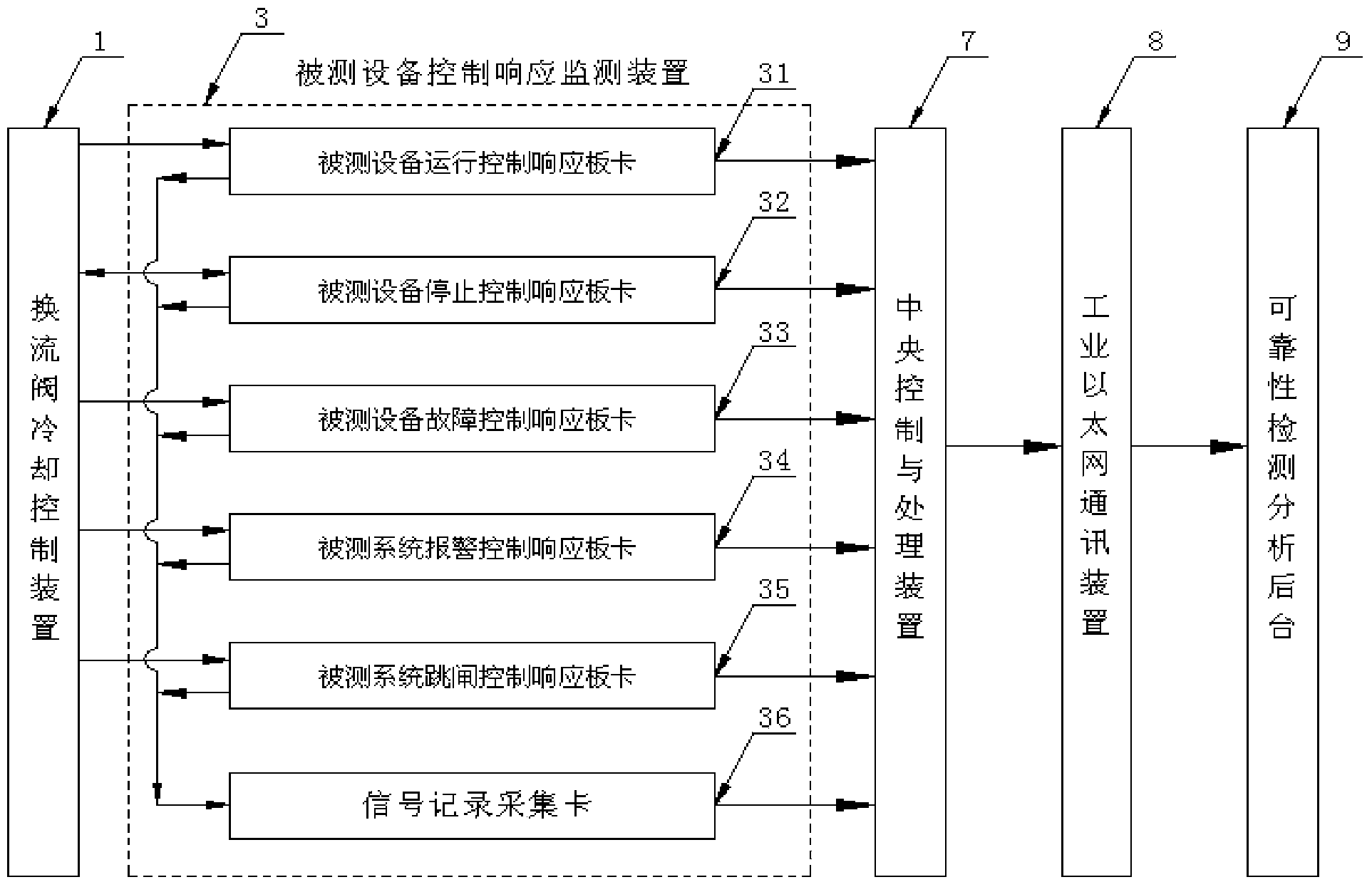

[0110] Please refer to figure 1 As shown, this embodiment discloses a reliability detection system for a converter valve cooling control device, which mainly includes a state signal monitoring device 2 of the device under test, a control response monitoring device 3 of the device under test, a sensor fault monitoring device 4 of the device under test, The key control component failure monitoring device 5 under test, the clock synchronization device 6, the central control and processing device 7, the industrial Ethernet communication device 8, and the reliability detection and analysis background 9 are composed. Among them: the state signal monitoring device 2 of the equipment under test is used to monitor the state signal of the converter valve cooling control device 1, so as to obtain the consistency detection information of the redundant signal under test, and the redundant signal at least includes the operation of the equipment under test , stop, fault, alarm and trip signa...

example 52

[0328] Based on example 5.2, after 1 CPU module, 1 main pump contactor failure PKM, 1 Fl flow sensor and other 3 control components fail, in addition to affecting the system availability, it will also affect the consistency rate, fast rate and stability rate of the system After calculation, the consistent rate Cj=0.9599, the fast rate Rk=0.9875, the stable rate Sm=0.8001, and the available rate Qn=0.93462185, then

[0329] Pi=i1×Cj+i2×Rk+i3×Sm+i4×Qn=0.9165, which is close to 0.9. According to engineering experience, the reliability of this system has dropped greatly and requires power-off maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com