Process method for automatically separating cable

A process method and cable technology, applied in the direction of line/collector components, electrical components, circuits, etc., can solve the problems of inability to adapt to the manufacturing process, cable splitting, slowness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

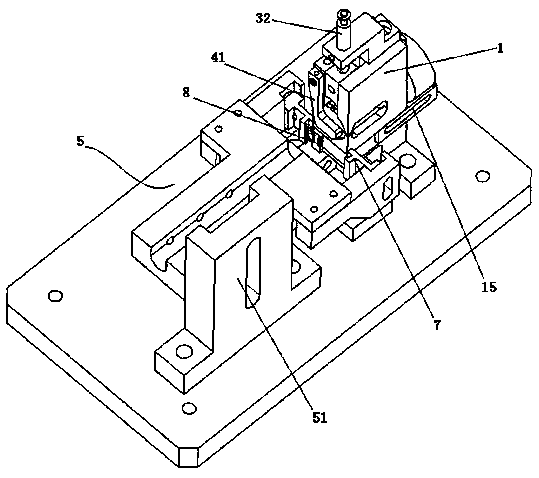

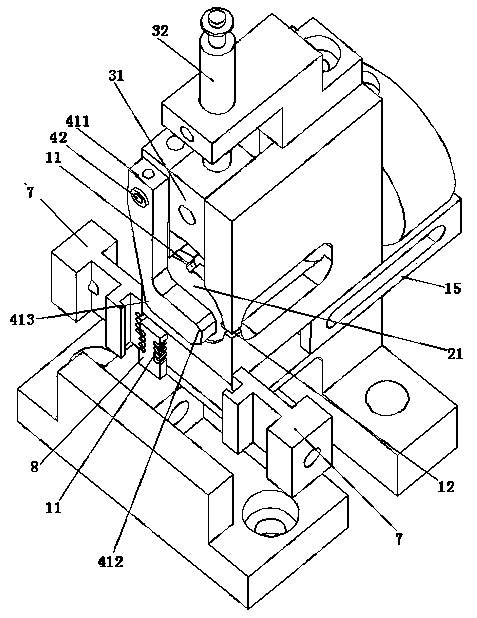

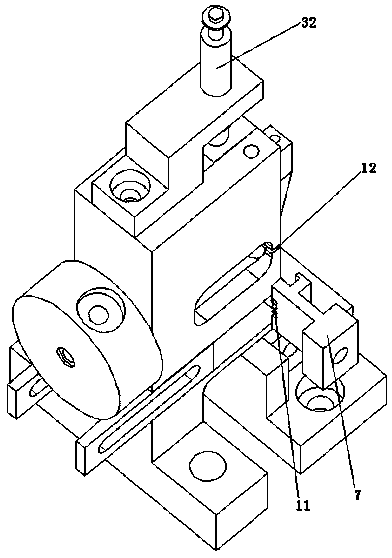

[0036] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0037] Such as figure 1 - As shown in 12, a process method for automatic wire splitting of cables, the device for automatic wire splitting includes: a wire splitting device 2, a wire pressing device 3 and a wire pulling device 4 arranged on the frame body 1 and cooperating with each other , and the CCD camera 6 and at least one mold 7 arranged on the outside of the frame body 1, including the following steps to complete the process method:

[0038] (1) Clamp the cables 9 including multiple wire harnesses 10 as a whole between the wire crimping door 31 and the wire distribution tray 21, and the wire crimping door 31 always keeps the pressing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com