Coarse tuning and fine tuning combined infrared image automatic focusing method

An infrared image and auto-focusing technology, applied in the field of image processing, can solve the problem that the sharpness evaluation function is difficult to achieve the best adjustment effect, and achieve the effect of being conducive to engineering application, strong real-time performance, and the best focusing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

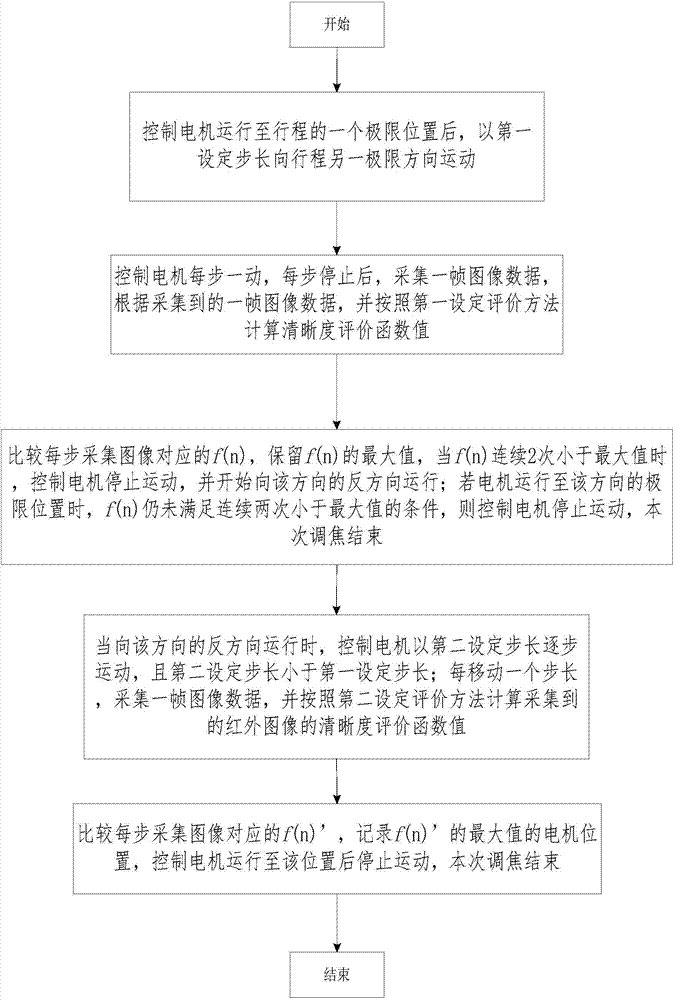

[0018] Such as figure 1 Described is the flowchart of the infrared image automatic focusing method combined with coarse and fine adjustment of the present invention. As can be seen from the figure, the method includes the following steps:

[0019] (1) Control the motor to run to the limit position in one direction of the stroke according to the auto-focus command;

[0020] (2) Control the motor to move from the limit position to the opposite direction with the first set step length, collect one frame of image data for each step, and calculate the clarity of the collected infrared image according to the first set evaluation method Evaluation function value f(n);

[0021] (3) Compare the f(n) corresponding to the images collected at each step, and retain the maximum value of f(n). When f(n) is less than the maximum value for two consecutive ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com