A kind of anti-ultraviolet absorber used in pesticide preparation

A technology of anti-ultraviolet and pesticide preparations, applied in the direction of application, insecticide, biocide, etc., to achieve the effect of improving the control effect, delaying photolysis, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

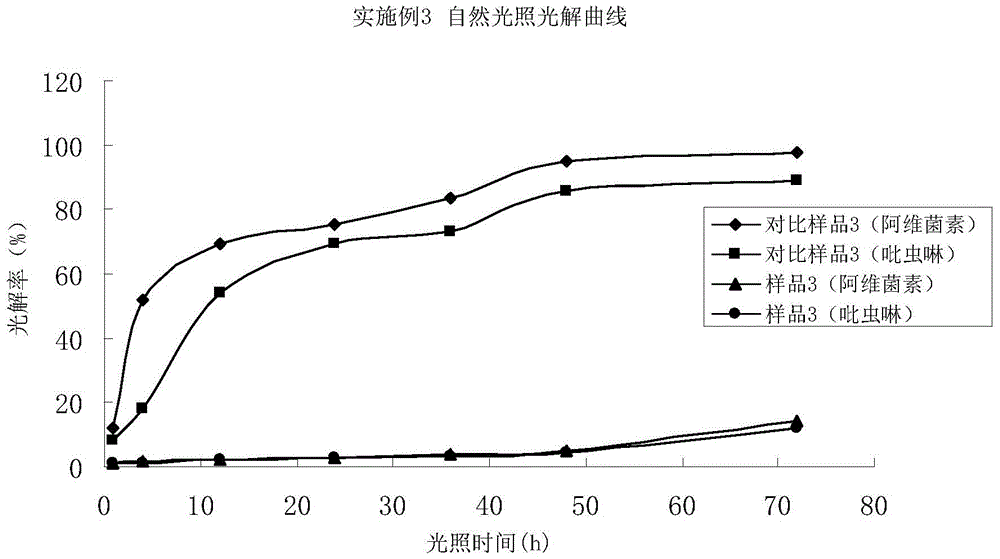

Examples

preparation example Construction

[0046] 1. Sample preparation:

[0047] According to the production formula, 2000g of pesticide preparations of each dosage form was divided into two equal samples, one with ultraviolet absorber added to the preparation according to a certain proportion, and the other without ultraviolet absorber as a comparison sample.

[0048] 2. Sample handling:

[0049] Take the prepared sample, including the UV absorber sample and the control sample, accurately weigh 2.5ml with a pipette gun and add it to a 250ml volumetric flask, dilute to 250ml with water (that is, dilute 100 times), stir the sample to disperse evenly, and use a pipette Take a 2ml sample with a gun and spread it flat on a clean 9cm-diameter petri dish, and immediately put it in a self-made darkroom, and wait for the solvent to evaporate completely at room temperature to form a thin drug film.

[0050] 3. Photolysis test treatment

[0051] Take out the petri dish that formed the drug film, and divide it into three group...

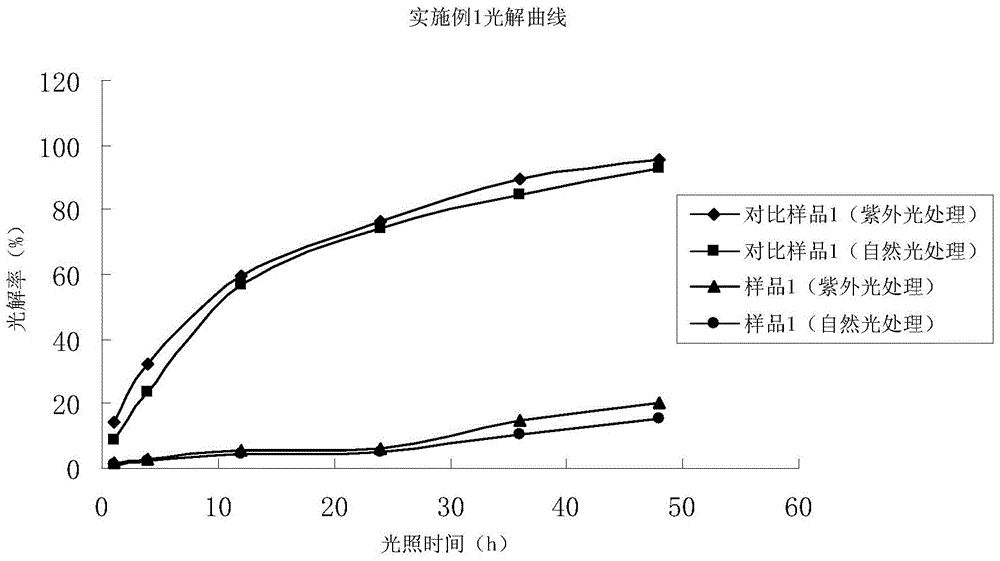

Embodiment 1

[0066] 2% emamectin emulsifiable concentrate (sample 1)

[0067] Put 2.3kg emamectin benzoate, 6kg tristyrylphenol polyoxyethylene ether, 0.01kg 2,6-dimethoxy-4-p-isothiazole carboxamide butenylphenol into the mixing kettle, 2kg dodecyl Calcium benzenesulfonate, 25kg dimethyl carbonate, 100kg made up of sec-butyl acetate, fully stirred, promptly got 2% emamectin emulsifiable concentrate (sample 1).

[0068] 2% emamectin emulsifiable concentrate (comparative sample 1)

[0069] In the mixing kettle, drop into 2.3kg emamectin benzoate, 6kg tristyrylphenol polyoxyethylene ether, 2kg calcium dodecylbenzenesulfonate, 25kg dimethyl carbonate, and sec-butyl acetate make up 100kg, fully stir evenly, namely Obtain 2% emamectin emulsifiable concentrate (comparative sample 1).

[0070] The above two samples were processed according to the test method and steps of the present invention, and finally obtained 1h, 4h, 12h, 24h, 36h, 48h of each time period of darkroom, ultraviolet light and...

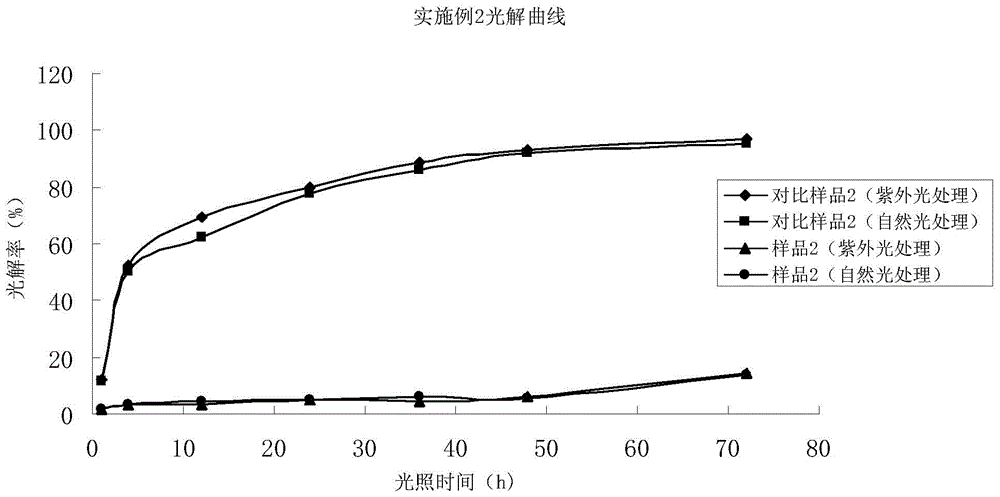

Embodiment 2

[0090] 3.2% Abamectin EC (sample 2)

[0091] Put 3.2kg of abamectin emulsifiable concentrate into the mixing tank, pump in 25kg of ethyl acetate, stir to complete the dissolution of abamectin, and then put in 0.05kg of 2,6-dimethoxy-4-p-isothiazole carboxamide butene Phenylphenol, 6kg nonylphenol polyoxyalkylene ether, trimethylbenzene make up to 100kg, fully stir, obtain 3.2% abamectin emulsifiable concentrate (sample 2).

[0092] 3.2% Abamectin EC (comparative sample 2)

[0093] Add 3.2kg abamectin emulsifiable concentrate into mixing, stir after sucking in 25kg ethyl acetate and finish dissolving abamectin, then drop into 6kg nonylphenol polyoxyalkylene ether, trimethylbenzene to make up to 100kg, fully stir, get 3.2 % Abamectin EC (comparative sample 2).

[0094] The above-mentioned two samples are processed according to the test method and steps of the present invention, and finally obtain darkroom, ultraviolet light and natural light irradiation treatment samples of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com