wiping device

A technology of wiping liquid and wiping head, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, cleaning methods using tools, etc., and can solve problems such as low efficiency, low degree of automation, and unsuitability for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

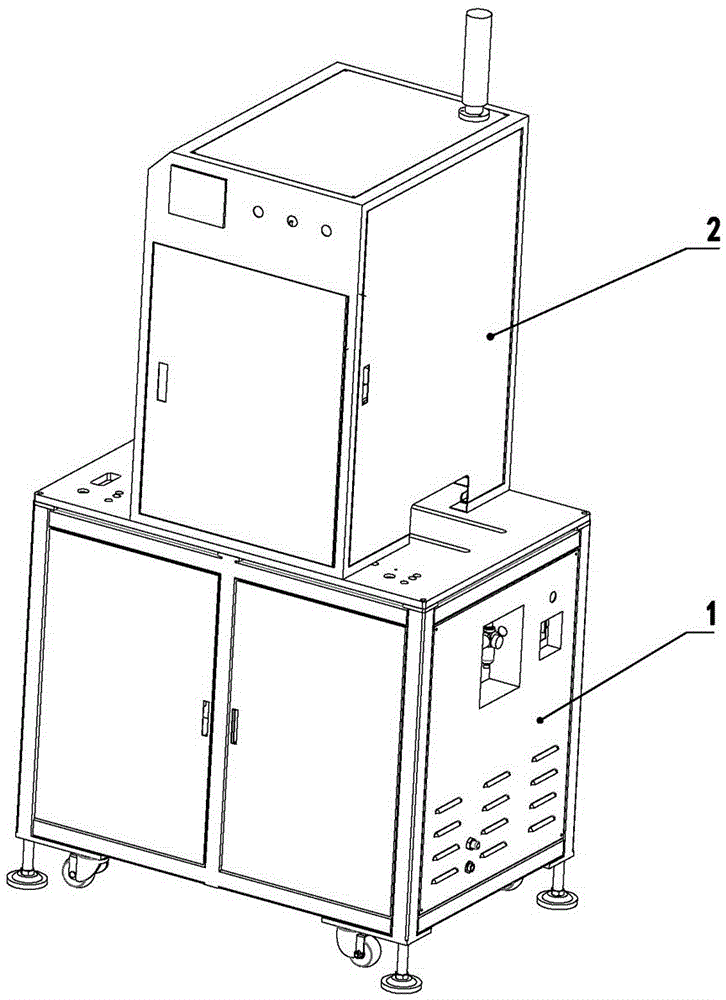

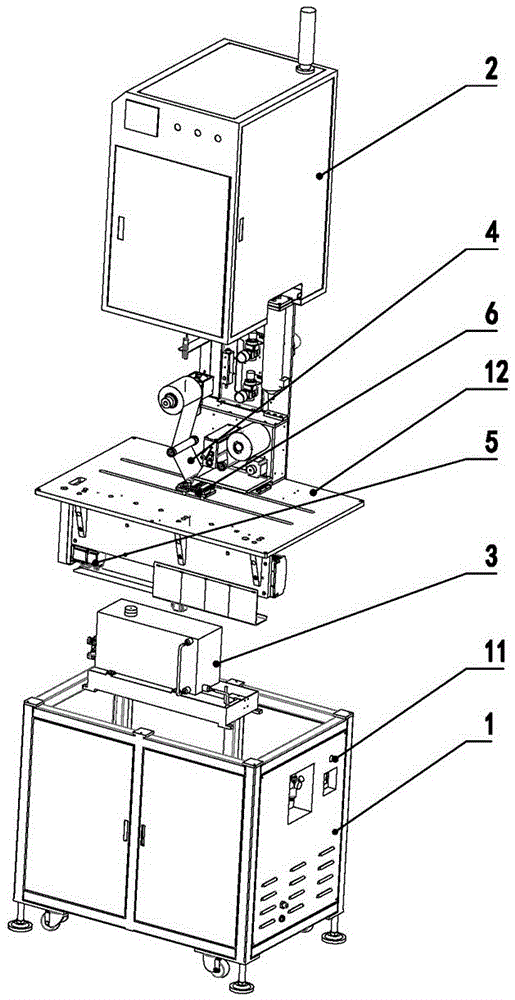

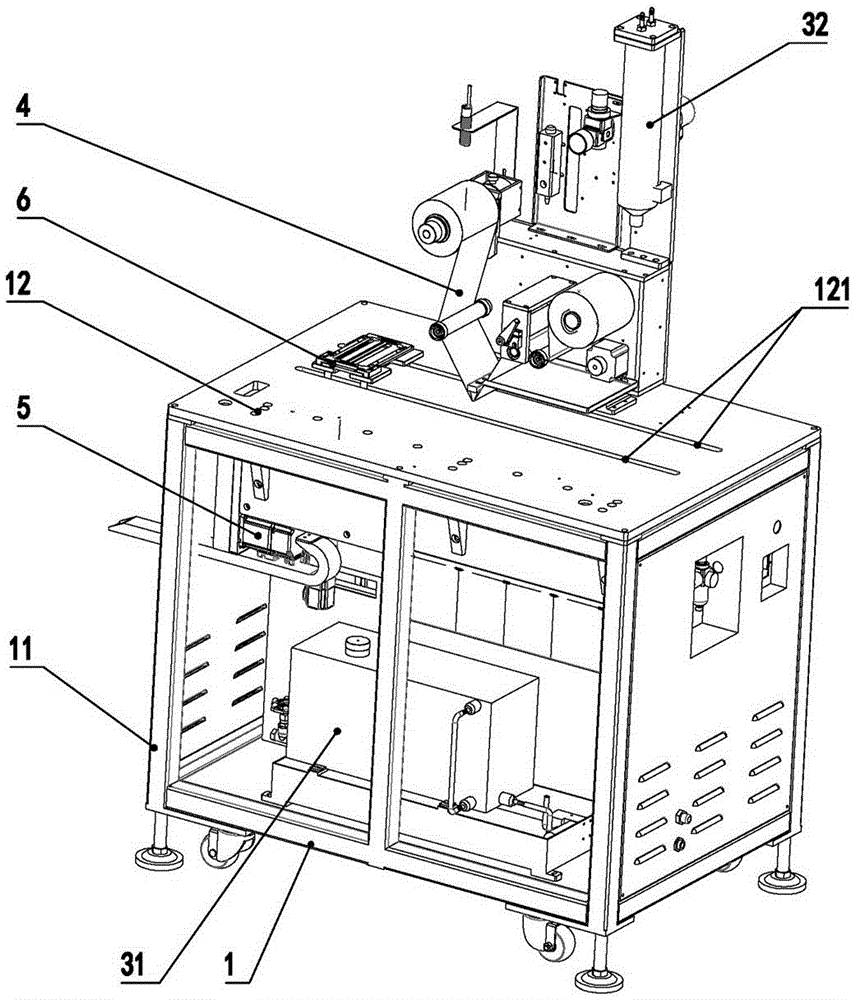

[0025] Figure 1 to Figure 9 The reference numerals in are: base 1; base box 11; base top cover 12; guide rail through hole 121; outer cover 2; wiping liquid delivery mechanism 3; main storage mechanism 31; wiping liquid main storage container 311; delivery pump 312; Liquid level display tube 313; discharge switch 314; bottom plate 315; liquid injection port 316; sub-storage mechanism 32; wiping liquid sub-storage container 321; liquid level sensor 322; delivery control valve 323; adapter 324; ; Conveying roller mount 40; Unwinding roller 41; Tension roller 42; Wiping head 43; Driven pressure roller 44; Active pressure roller 45; Wiping body detection sensor 49; manipulator 5; horizontal feeding mechanism 51; lifting feeding mechanism 52; clamp 6; fixed plate 61; lifting plate 62; spring 63; guide shaft 64; 67; Guide installation block 68; Ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com