Clutch device and adjustment method for roll adjustment on blanking machine

A technology of clutch device and blanking machine, which is applied in the direction of mechanically driven clutches, clutches, and clutches that mesh with each other. It can solve problems that affect rolling effects, rolling imbalances, and loss of level, so as to improve work smoothness and increase production. Efficiency, easy operation and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

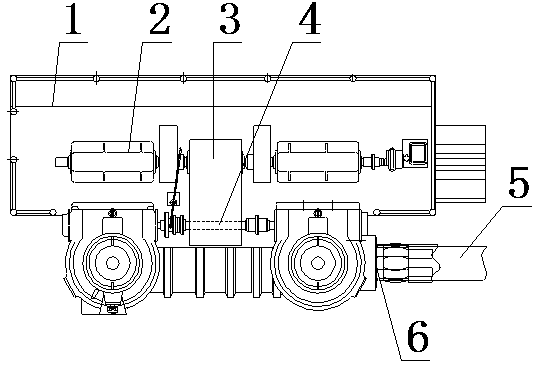

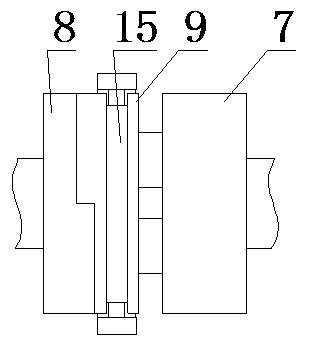

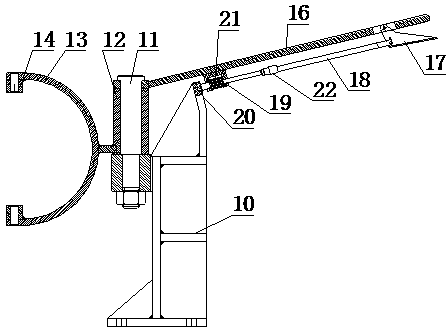

[0021] Specific implementation methods: such as Figure 1-Figure 3 As shown, a part structure of the blanking machine that adopts the clutch device of the present invention includes a pressing motor 2 arranged on the frame 1 above the upper roll, and the output end of the pressing motor 2 is connected to the pressing speed reducer 3. The lower speed reducer 3 has an output shaft 4 arranged in parallel above the upper roller 6, and both ends of the output shaft 4 of the reduction speed reducer extend out of the speed reducer housing and form two power output ends for depression, and two power output ends for depression Each is connected through a steering connection transmission pair and a nut transmission connection. The nuts are respectively matched on a vertically arranged screw rod to form a screw nut transmission pair, which can drive the screw rod to move up and down. The screw rod is vertically arranged on the upper The position above the two ends of the roll 6 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com