Flexible accommodating structure, multi-point profile stretch bending mold and stretch bending molding method

A multi-point mold and bending mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as inability to adapt to the diversity of profile sections, and achieve shortening of forming production cycles, digital production methods, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

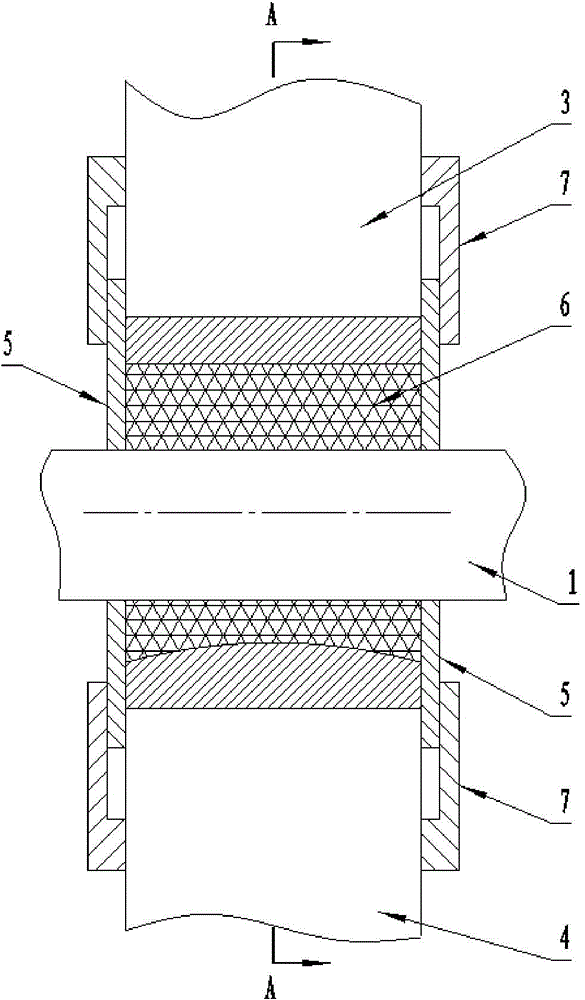

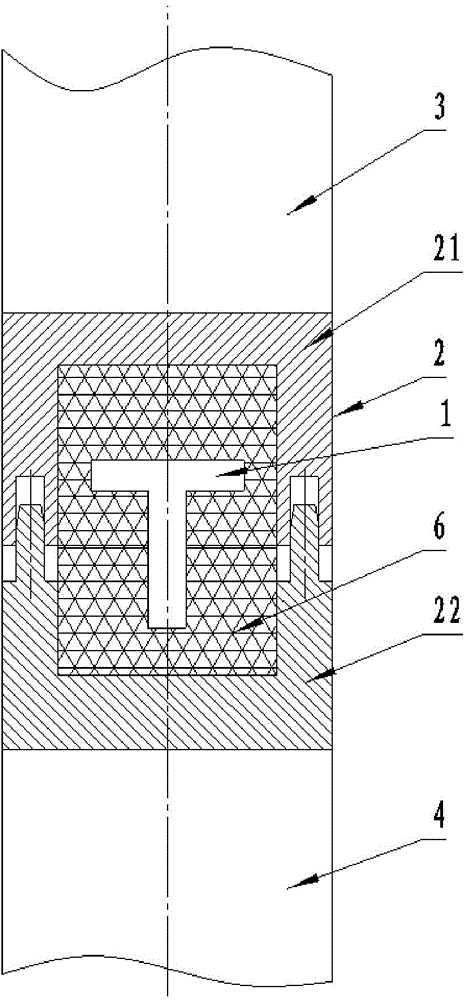

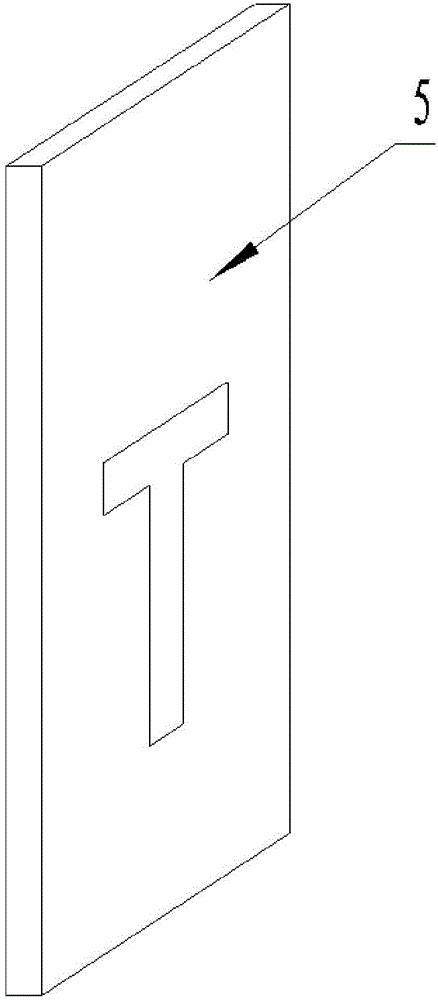

[0044]The flexible containment structure of the present invention will be described in further detail below in conjunction with the accompanying drawings. A flexible containment structure, including a ferrule 2 that can be set outside the profile 1, the top of the ferrule 2 is connected to the push cylinder 3, the bottom of the ferrule 2 is connected to the multi-point mold punch 4, and the two ends of the ferrule 2 The end face baffles 5 used to block the ferrule 2 are respectively provided. The end face baffle 5 is provided with a through hole 51 for the profile 1 to pass through. The ferrule 2 and the end face baffles 5 at both ends of the ferrule 2 enclose the closed space. It is filled with a flexible filler 6 capable of wrapping the profile 1, such as figure 1 , figure 2 and image 3 shown.

[0045] When in use, pass the profile 1 through the ferrule 2, the end baffle 5 and the flexible filler 6, so that the flexible filler 6 is always tightly attached to the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com