Feeding and filling device for automatic forming equipment

An automatic molding and injection technology, which is applied in the field of material feeding and injection devices, can solve the problems of poor operation stability, increased device volume, and high manufacturing cost, and achieve the effects of easy movement, small footprint, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

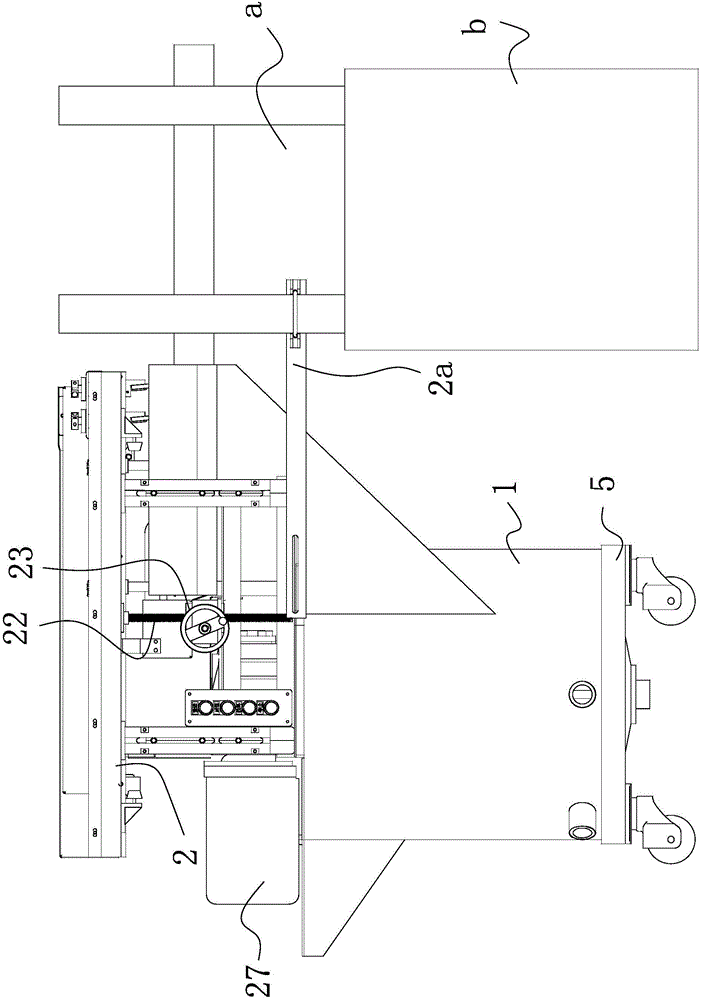

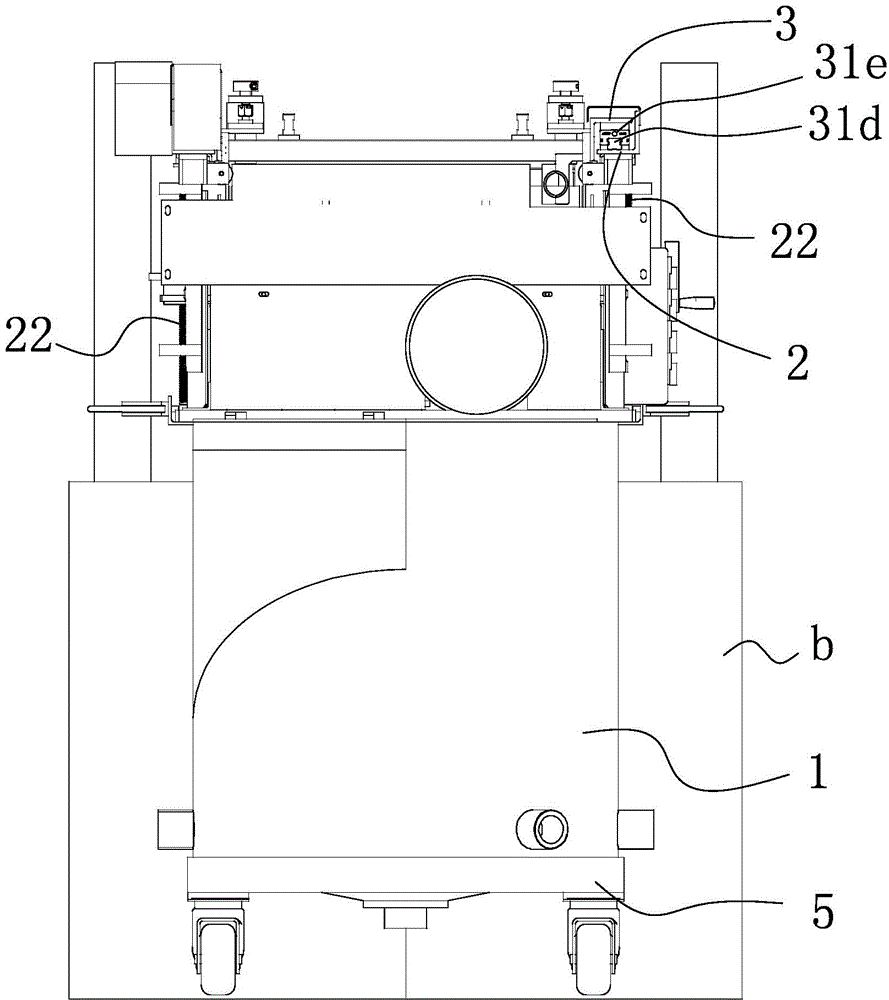

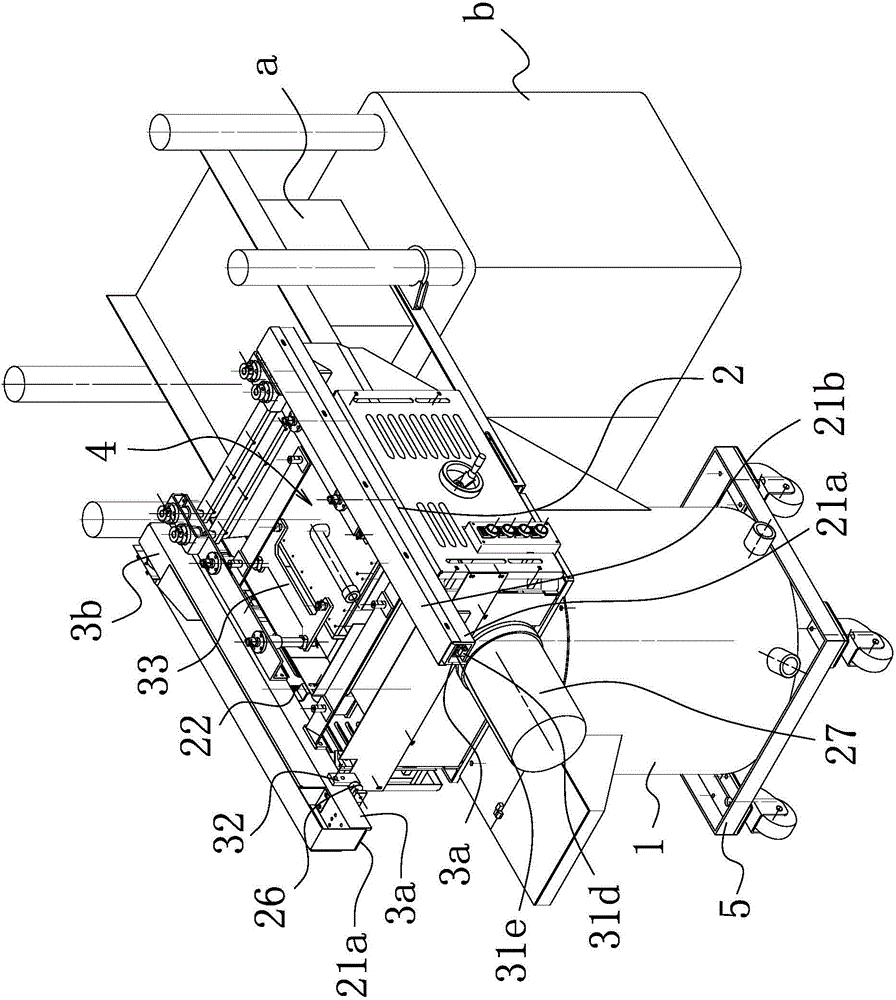

[0029] Such as Figure 1-8 As shown, the feeding and injection device of the automatic molding equipment includes a material barrel 1, which is arranged on a movable frame 5, and the bottom of the movable frame 5 has a plurality of rollers, which can be easily moved and have good flexibility. A frame 2 is arranged on the top of the material barrel 1, and one end of the frame 2 is a cantilever end extending to the outside of the material barrel 1, and an auxiliary connecting frame 2a that can be connected with the molding press b is provided on the material barrel 1, and the frame 2 is provided with a moving frame 3 capable of reciprocating movement along the frame 2, and the moving frame 3 is connected to a driving mechanism 31 capable of driving the moving frame 3 to reciprocate, and the driving mechanism 31 includes a rack 31a arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com