Hydraulic windlass with rope guider

A technology of hydraulic winch and rope arranging device, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems of wire rope loose loop, wire rope jumping out of reel, uneven winding of wire rope, etc., to achieve uniform winding, reduce impact and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

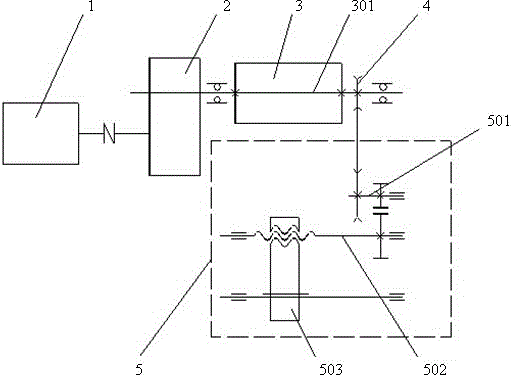

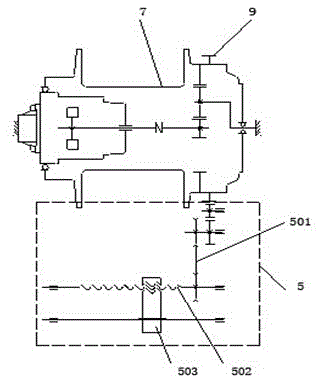

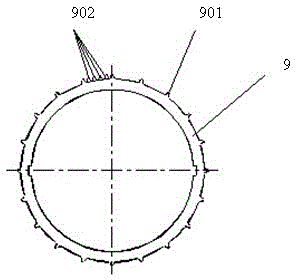

[0015] like figure 1 , figure 2 and image 3 Shown, a kind of hydraulic capstan 7 with rope row device 5 comprises hydraulic capstan 7, motion and power output gear and rope row device 5, and described hydraulic capstan 7 is provided with capstan reel 3, motion and power output gear and row The rope device 5 is arranged on the shell of the winch drum 3, and the motion and power output gears adopt a gear structure with uniform lack of teeth on the circumference. Chain 501 head shaft gear meshes, transmission chain 501 is connected with two-way screw rod 502, said two-way screw rod 502 is provided with working parts of rope puller 5, and said winch reel 3 is provided with oil motor 1 and multi-stage planetary Reducer 2, the outer surface 701 of the planetary reducer 2 housing is provided with a sprocket 4, and the tooth-missing gear 9 for m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com