Small-amplitude synchronous lifting platform

A synchronous lifting, small-scale technology, applied in the direction of lifting frame, lifting device, etc., can solve the problem of unable to meet the requirements of future freight vehicle reorganization, fast synchronous loading and unloading, labor costs and equipment use, high maintenance costs, procurement and use, maintenance costs Advanced problems, to achieve the effect of small deformation, high stiffness and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

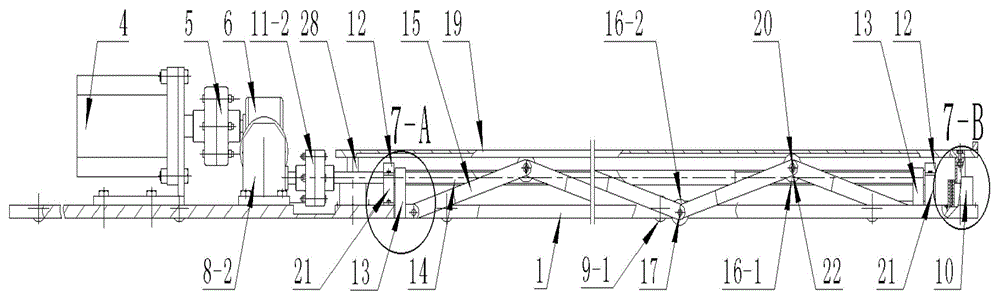

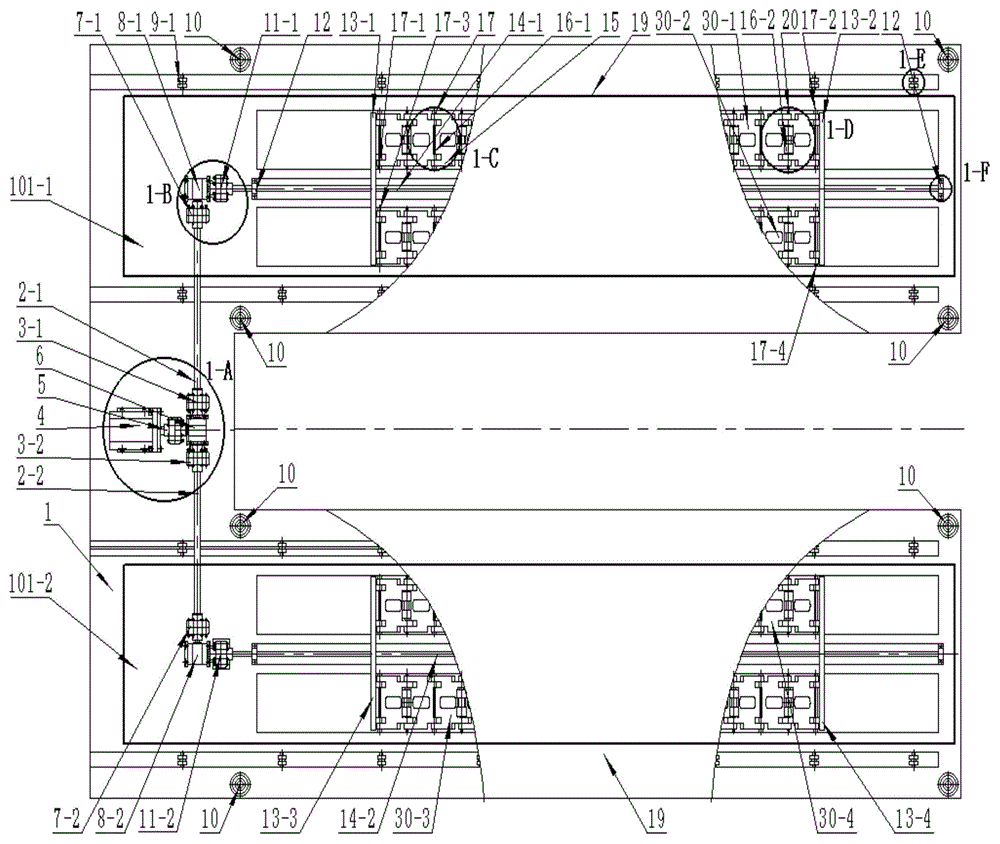

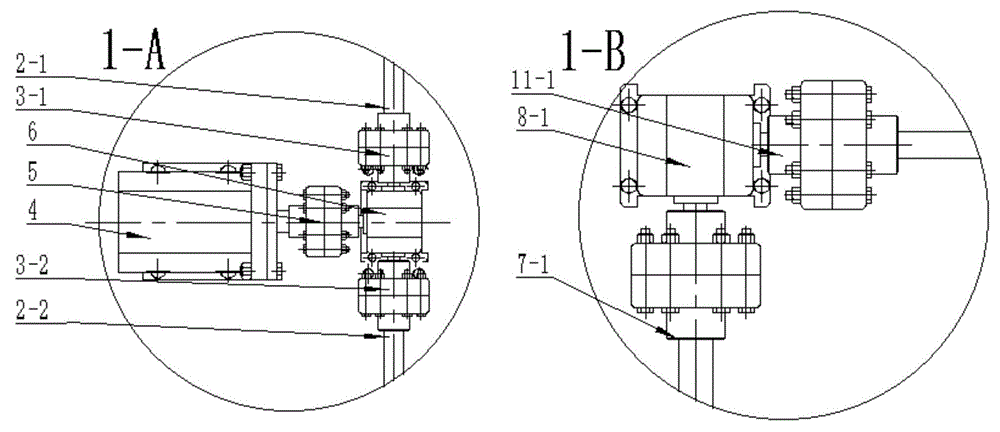

[0028] A small amplitude synchronous lifting platform, such as figure 1 and figure 2 As shown, it is a symmetrical structure, which includes: underframe 1, loading plate 19, lifting drive motor 4, motor coupling 5, bidirectional output reducer 6, first reducer coupling 3-1, first The transmission shaft 2-1, the first transmission mechanism 101-1, the second reducer coupling 3-2, the second transmission shaft 2-2, and the second transmission mechanism 101-2; also include eight longitudinally positioned contraction frames 10 And four groups of driven roller groups 9;

[0029] The underframe 1 is a U-shaped structure symmetrical to the centerline;

[0030] Among them: the lifting drive motor 4 and the bidirectional output reducer 6 are installed on the chassis 1, the output shaft of the lifting drive motor 4 is connected to the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com