Graphical processing method of nanopillar/needle forest structure

A processing method and nano-column technology, applied in the direction of nano-structure manufacturing, nanotechnology, nanotechnology, etc., can solve the limitations of integrated application of nano-column/needle forest structure, difficult pattern arrangement of single-layer balls, and increased process complexity and other issues, to achieve the effects of enhanced optical absorption characteristic plasmon oscillation, improved production efficiency and integration, large surface area and surface-to-volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The first substrate 101 is made of silicon material, the second substrate 102 is made of silicon material, and the first substrate similar material layer 103 is the surface layer of the second substrate 102 and is also made of silicon material. The experimental methods described in the following examples are conventional methods unless otherwise specified.

[0043] a. Prepare and clean the selected first substrate 101 and second substrate 102;

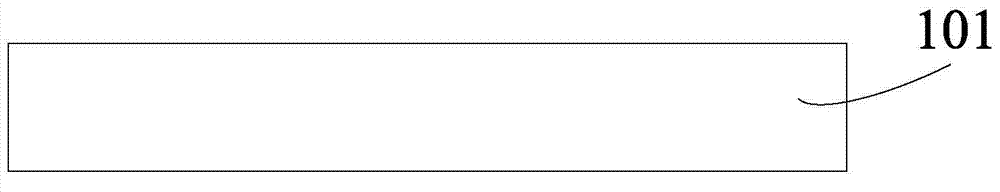

[0044] like figure 1 , the first substrate 101 is a silicon substrate that finally obtains a nano-column / needle forest structure 401 on its surface, and the second substrate 102 is a material layer for realizing a hollow substrate, which needs to be cleaned before the experiment, specifically The cleaning process will not be repeated.

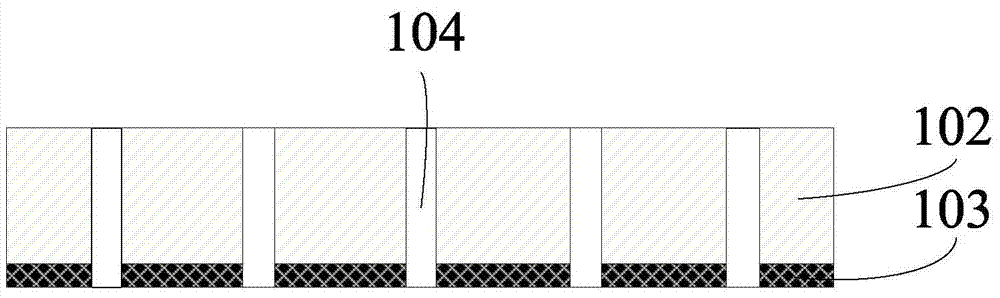

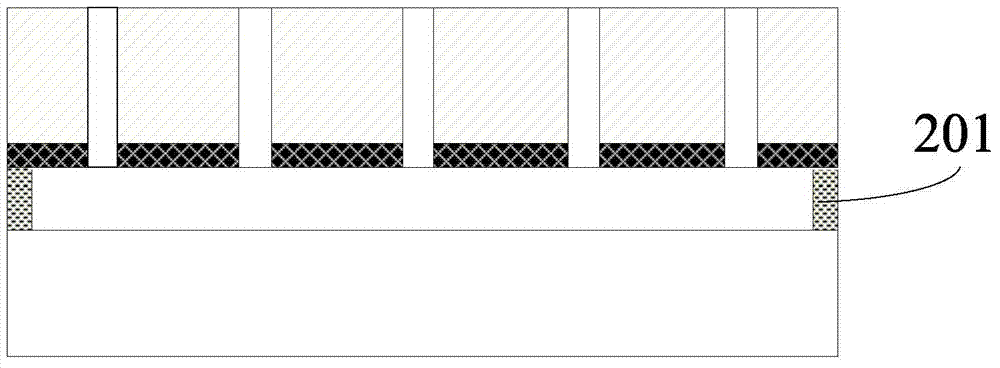

[0045] b. A first substrate-like material layer 103 similar to that of the first substrate 101 is provided on the lower surface of the above-mentioned second substrate 102, and several through ...

Embodiment 2

[0054] The first substrate 101 is made of glass material, the second substrate 102 is made of glass material, and the layer 103 of similar material to the first substrate is the surface layer of the second substrate 102 and is also made of glass material. The experimental methods described in the following examples are conventional methods unless otherwise specified.

[0055] a. Prepare and clean the selected first substrate 101 and second substrate 102;

[0056] like figure 1 , the first substrate 101 is a glass substrate with a nano-column / needle forest structure finally obtained on its surface, and the second substrate 102 is a material layer for realizing a hollow structure, also using glass, which needs to be cleaned before the experiment.

[0057] b. A first substrate-like material layer 103 similar to that of the first substrate 101 is provided on the lower surface of the above-mentioned second substrate 102, and several through structures 104 are arranged on the secon...

Embodiment 3

[0066] The first substrate 101 is made of silicon material, the second substrate 102 is made of glass material, and the material layer 103 similar to the first substrate is made of amorphous silicon material. The experimental methods described in the following examples are conventional methods unless otherwise specified.

[0067] a. Prepare and clean the selected first substrate 101 and second substrate 102;

[0068] like figure 1 , the first substrate 101 is the silicon substrate on which the nano-column / needle forest structure 401 is finally obtained on the surface, and the second substrate 102 is a material layer for realizing the hollow structure, which needs to be cleaned before the experiment.

[0069] b. A first substrate-like material layer 103 similar to that of the first substrate 101 is provided on the lower surface of the above-mentioned second substrate 102, and several through structures 104 are arranged on the second substrate 102. The through structures 104 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com