Method for contruction of tow-dimension ordered distributing silicon quantum point figurated nano structure

A technology of silicon quantum dots and nanostructures, which is applied in the field of patterned nanostructures of high-density silicon quantum dots, can solve the problems of controllability of nanometer quantum dots size and difficulty in patterning distribution order, and achieve strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

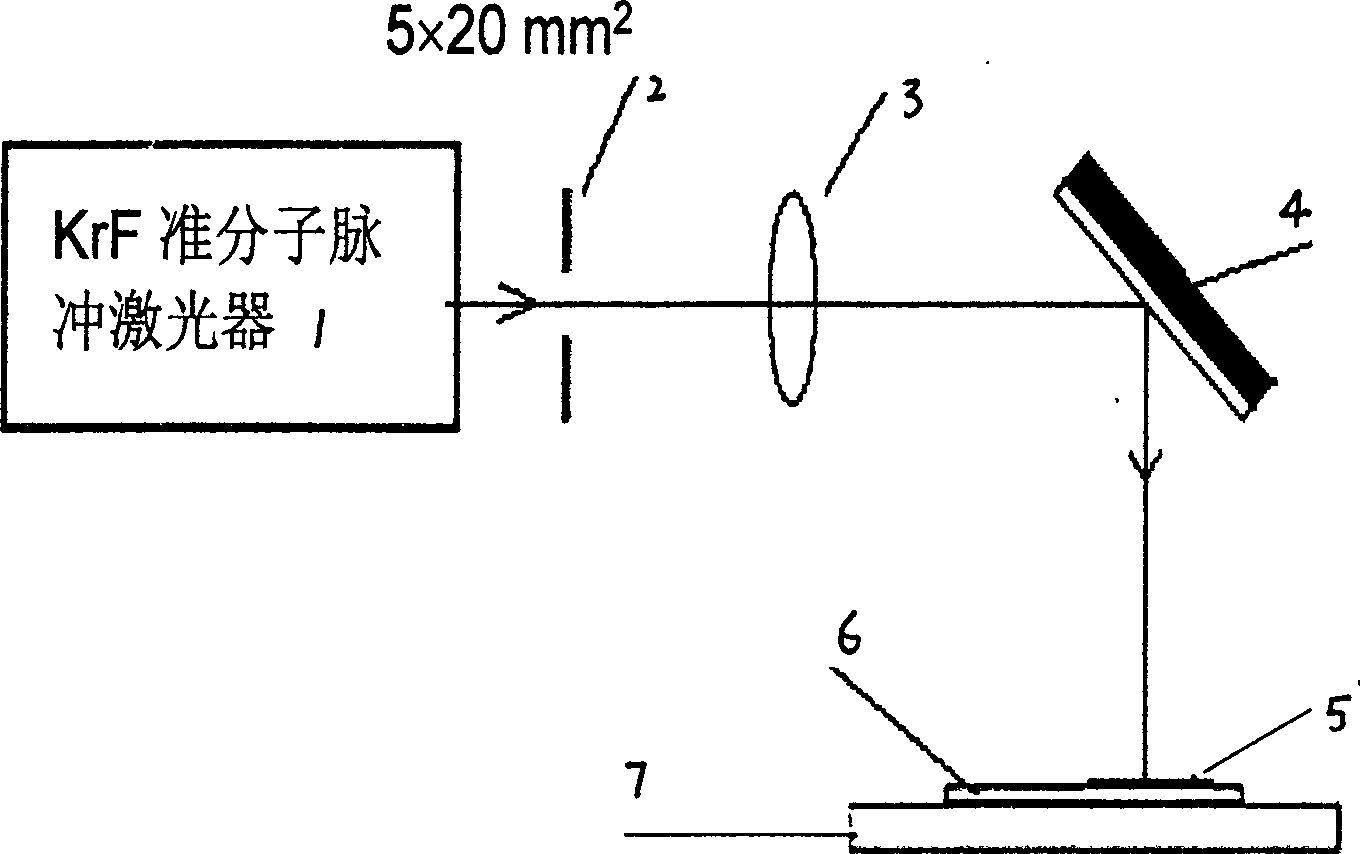

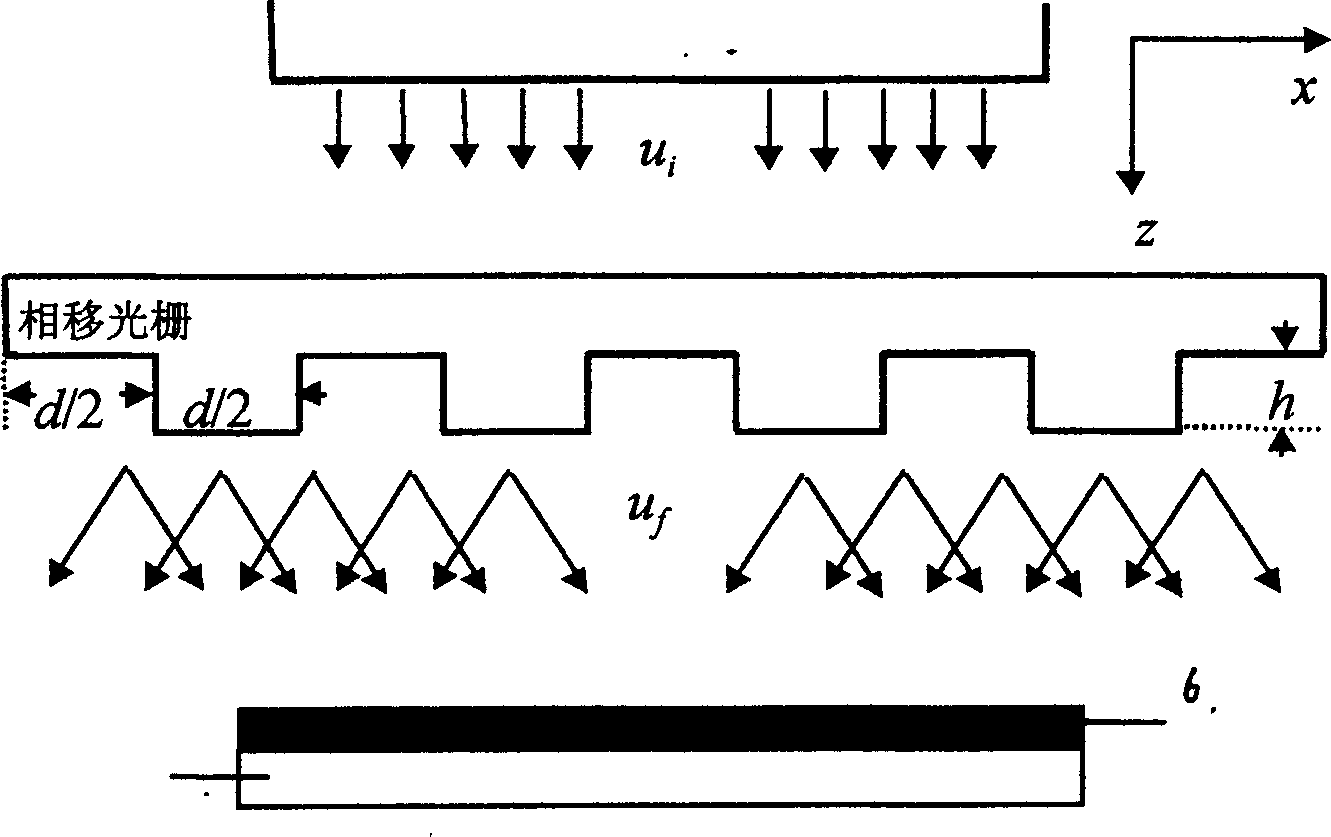

Method used

Image

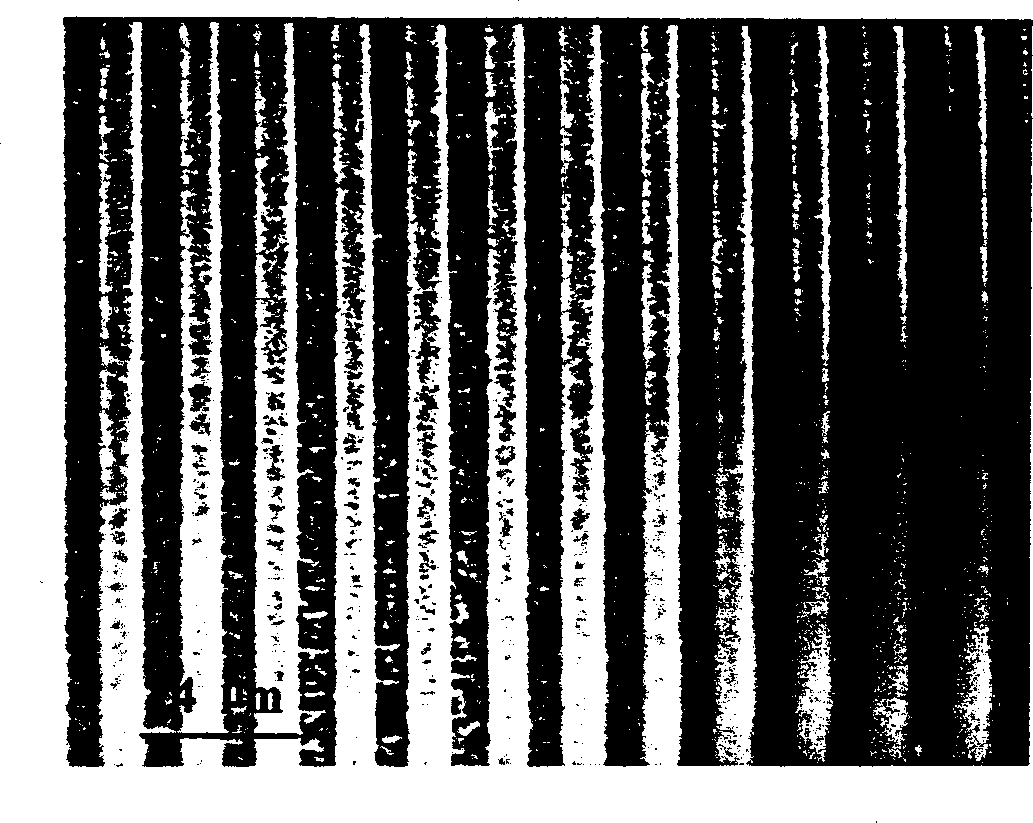

Examples

Embodiment Construction

[0023] 1. Preparation of ultra-thin amorphous silicon (a-Si) film: a-Si:H film was prepared by plasma enhanced chemical vapor deposition (PECVD). The thickness of the a-Si:H layer can be precisely controlled in the range of 1.0-10nm; the size of the quantum dots to be obtained after laser crystallization is basically consistent with the thickness of the a-Si:H layer. Similarly, we can also prepare (a-SiN X :H / a-Si:H / a-SiN X :H) Three-layer sandwich structure, which has a wider application in nanoelectronic devices.

[0024] a-Si:H film and a-SiN X :H / a-Si:H / a-SiN X :H Preparation of three-layer sandwich structure film:

[0025] Using computer-controlled plasma-enhanced chemical vapor deposition (PECVD) technology, using silane (SiH 4 ), ammonia (NH 3 ) and argon (Ar) as the reaction gas source; deposit a-Si:H film or a-SiN on single crystal silicon wafer and double-throw fused quartz or optical glass substrate X :H / a-Si:H / a-SiN X :H three-layer structure film. Concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com