Method and device for manufacturing optical thin film having concave structures on surface

A technology of optical film and concave structure, which is applied to optical elements, household appliances, and other household appliances. It can solve the problems that cannot meet the special needs of optical films, the surface of optical films has a single macroscopic structure, and the preparation process is complex. Improve the surface The effect of functional properties, simple technical means, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

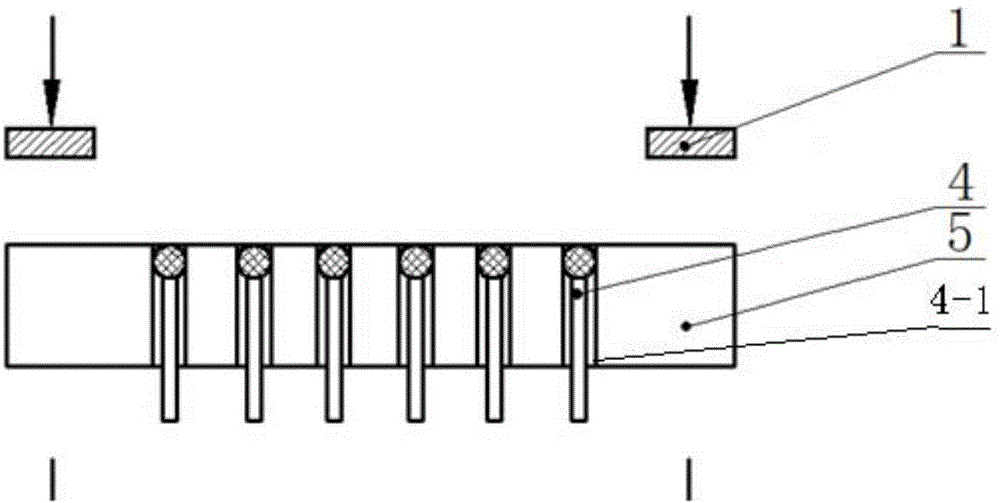

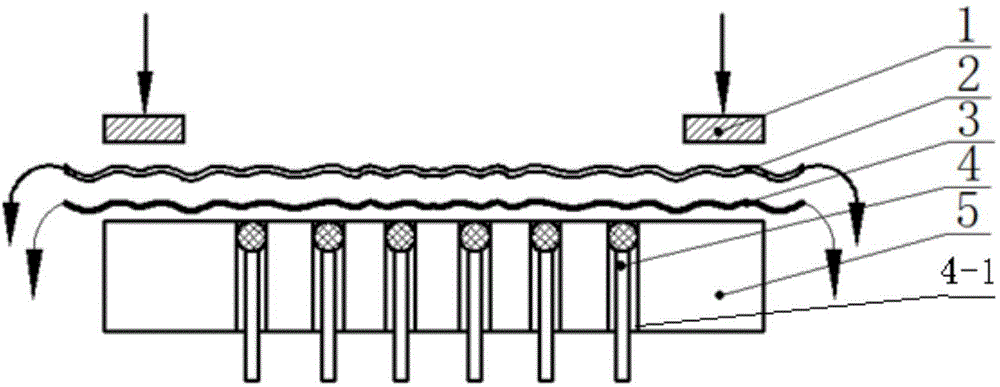

[0034] Such as figure 1 shown. The present invention is a device used in the preparation of an optical film with a concave structure on the surface. The device includes a mold body 5, a crimping mechanism 1 arranged on both sides of the mold body 5 for tightening the edge of the film template 2, and an array distributed on the mold The thimble channel 4-1 in the body 5, the thimble channel 4-1 is provided with a thimble 4, and the thimble 4 can move up and down on the upper surface of the mold body 5 and the thimble channel 4-1 through the jacking mechanism (using hydraulic pressure); The lifting mechanism is used to control the height of the ejector pin 4 on the upper surface of the mold body 5;

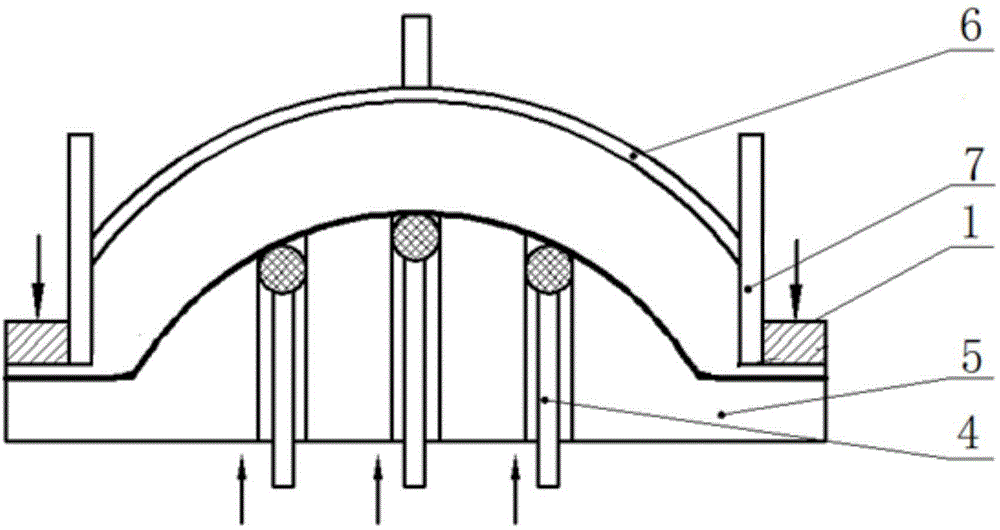

[0035] Such as Figure 5 mentioned. The mold also includes an auxiliary pressing plate 6, which is used to squeeze the silica gel 8 from top to bottom during the use of the mould. An auxiliary dam 7 for enclosing the colloid 8 is added on the inner side of the crimping mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com