Special economical and environment-friendly production device for nanofibers

A production device and nanofiber technology, applied in the field of chemical fiber manufacturing, can solve the problems of reducing the production efficiency of enterprises, low infiltration of nanofibers, and simple oiling process, so as to improve the oiling effect, avoid excessive oil, and avoid oiling. uneven oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

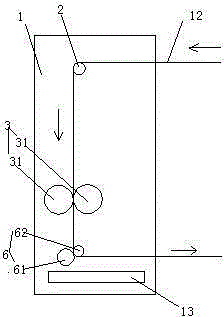

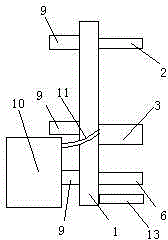

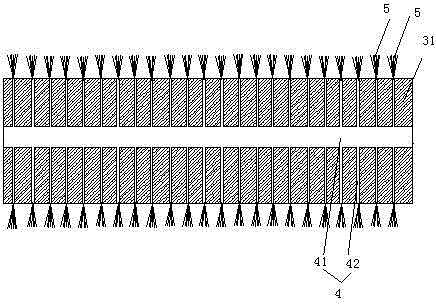

[0018] As shown in the figure, the present invention is a special energy-saving and environment-friendly production device for nanofibers, which includes a support frame 1, on which a guide roller 2 is arranged from top to bottom, an oiling roller group 3, and a pressing roller Group 6 and oil recovery device 13, the guide roller 2 is located at the top of the support frame 1, the oiling roller group 3 is located directly below the guide roller 2, and includes two oiling rollers 31, the oiling roller 31 It is a cylindrical structure, and the inside of the oil roller 31 is provided with an oil passage 4, and the oil passage 4 includes a main oil passage 41 and a plurality of sub-oil passages 42, and the main oil passage 41 is located at the The position of the central axis of the above-mentioned oiling roller 31 runs through the entire interior of the oiling roller 31. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com