High-efficiency nanofiber oiling roller

A nanofiber, high-efficiency technology, applied in the field of chemical fiber manufacturing, can solve the problems of simple oiling process, low nanofiber infiltration, and reduced production efficiency of enterprises, so as to improve the use effect, improve the oiling effect, and avoid oiling. average effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

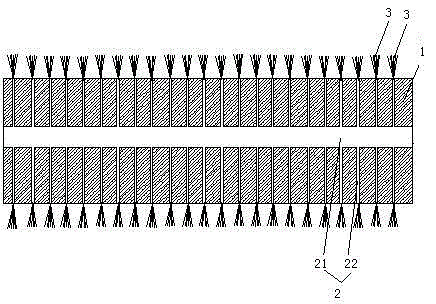

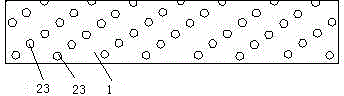

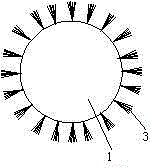

[0012] As shown in the figure, the present invention presents a high-efficiency nanofiber oiling roller 1, wherein, the oiling roller 1 has a cylindrical structure, and the oiling roller 1 is provided with an oil passage 2 inside, and the oil passage 2 The oil passage 2 includes a main oil passage 21 and a plurality of branch oil passages 22. The main oil passage 21 is located at the central axis of the oil roller 1 and runs through the entire interior of the oil roller 1. The branch oil passages 22 is in a straight line structure, one end is connected to the main oil channel 21, and the other end is connected to the surface of the oiling roller 1, and an oiling hole 23 is formed on the outer surface of the oiling roller 1, and the oiling hole 23 is on the outer surface of the oiling roller 1 It is evenly distributed in a spiral shape, and the outside of the oil hole 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com