Greasing device for crankshaft of piston compressor

A compressor crankshaft and piston type technology, which is applied to liquid variable volume machinery, mechanical equipment, variable volume pump components, etc., can solve the problems of incomplete oiling, complicated operation process, difficult cleaning, etc., and reduce physical waste. , easy to use, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

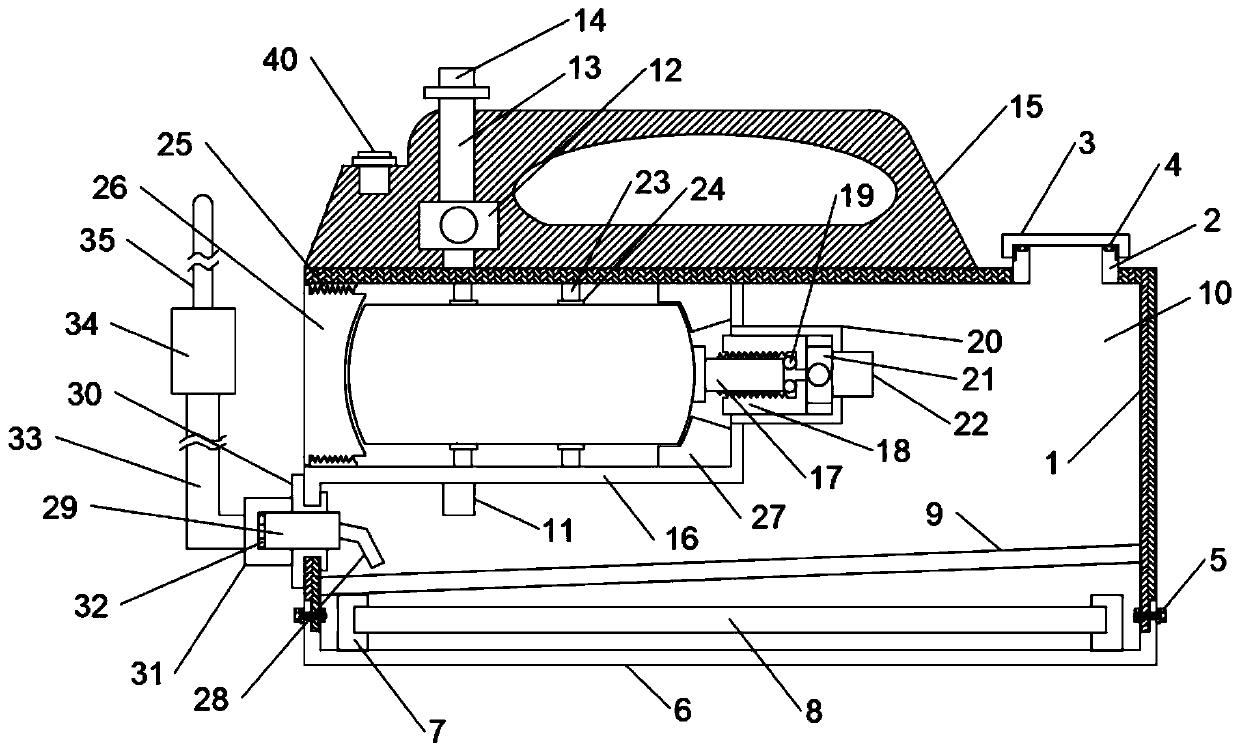

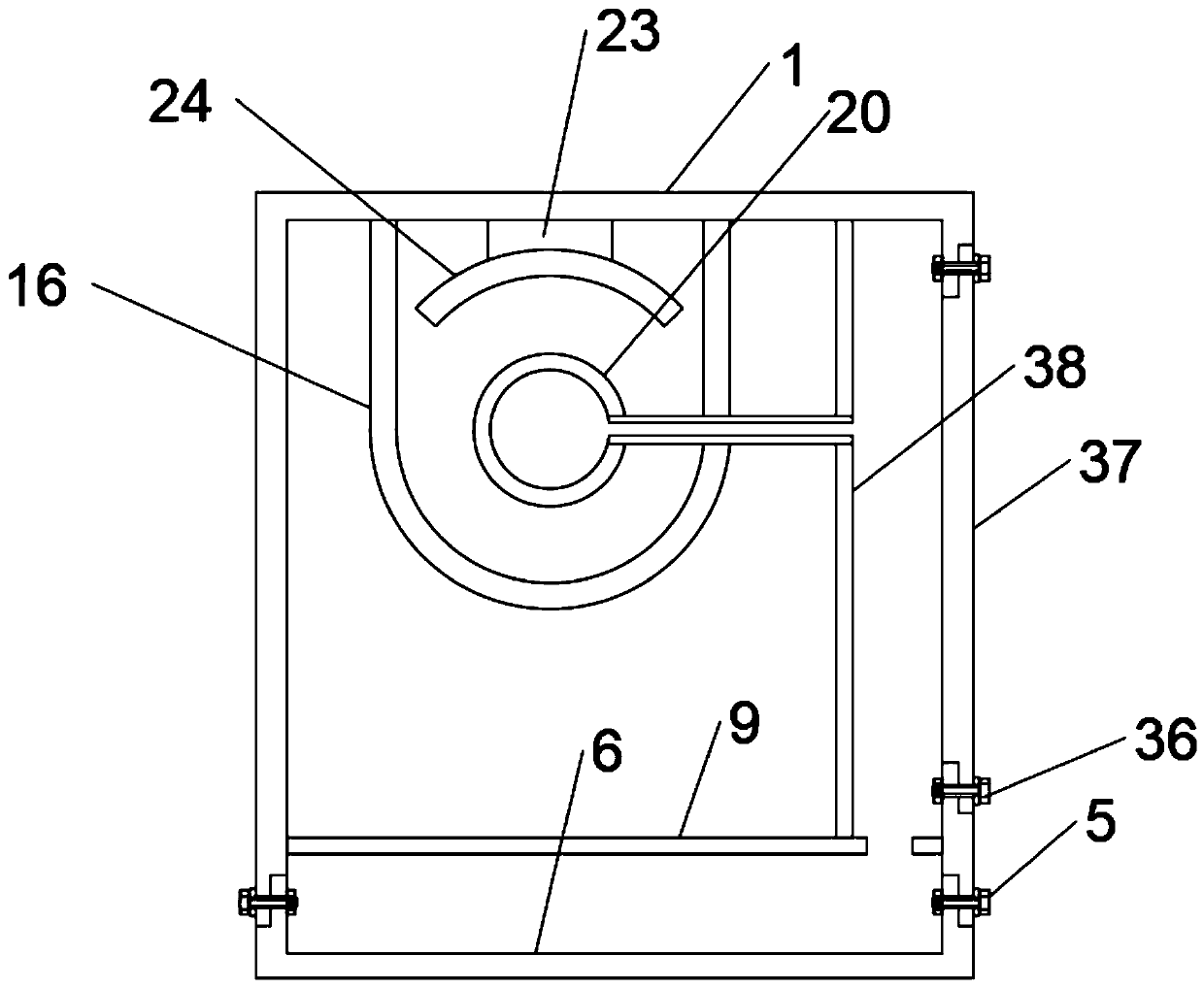

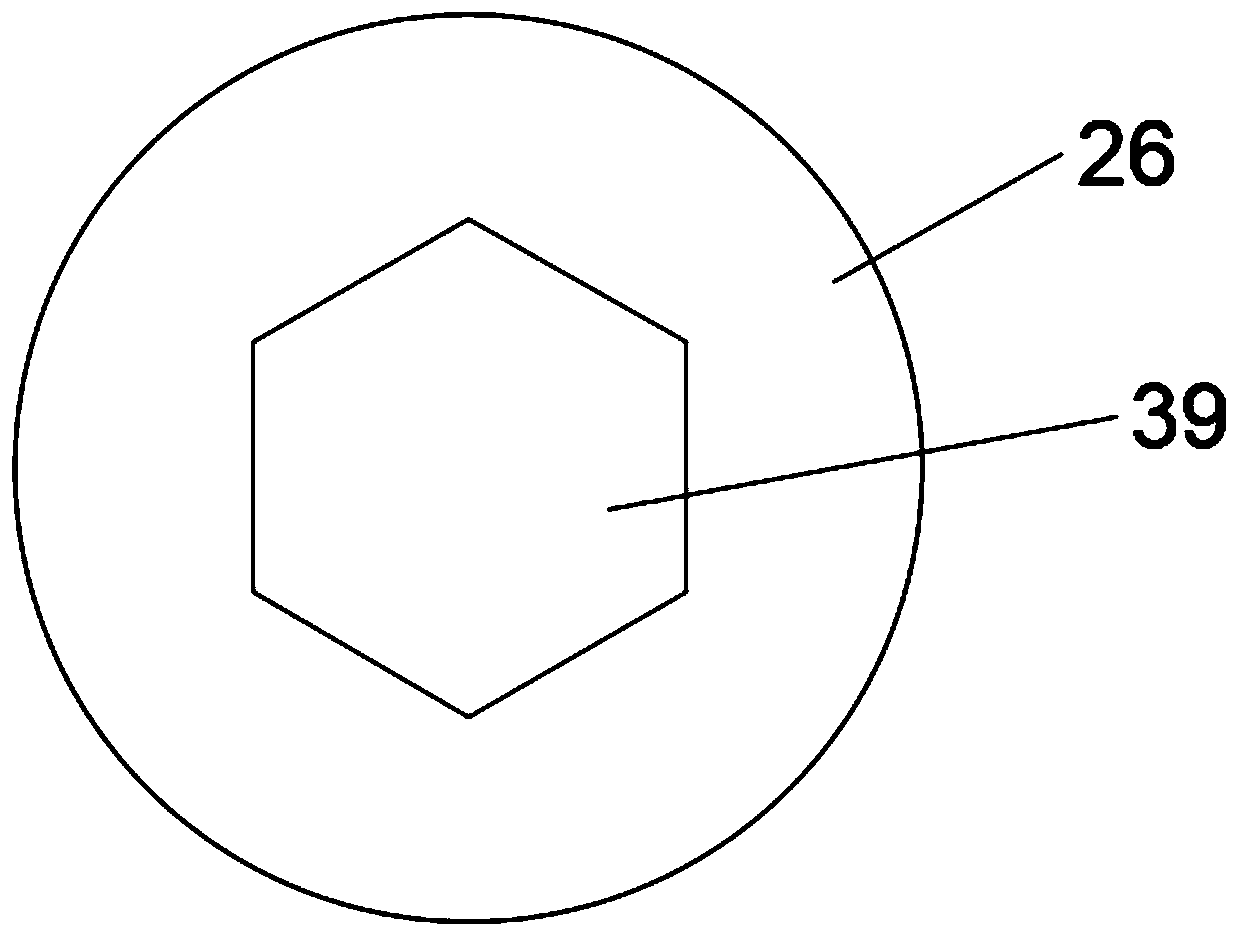

[0020] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a piston compressor crankshaft oiling device, including a pressure-resistant alloy shell 1, and one side of the upper side panel of the pressure-resistant alloy shell 1 is sealed and connected with a top inlet Oil port 2, the top oil inlet 2 is threadedly connected with a sealing cover 3, and the side surface of the pressure-resistant alloy shell 1 away from the top oil inlet 2 is connected with a bottom cover 6 through a bottom cover fixing bolt 5, so The side of the bottom cover 6 close to the pressure-resistant alloy shell 1 is connected with a battery plate 8 through the battery plate fixing frame 7, and the inside of the pressure-resistant alloy shell 1 on the side of the battery plate 8 away from the bottom cover 6 is sealed and connected with an inner tank Bottom plate 9, said pressure-resistant alloy casing 1 is sealed and connected with an inner partition 38, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com