Part oiling machine

A technology of oiling machine and parts, which is applied in the field of parts processing, can solve the problems of oil stains and other problems, achieve high stability, simple and easy structure, and increase the effect of structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is further described in detail by specific embodiments:

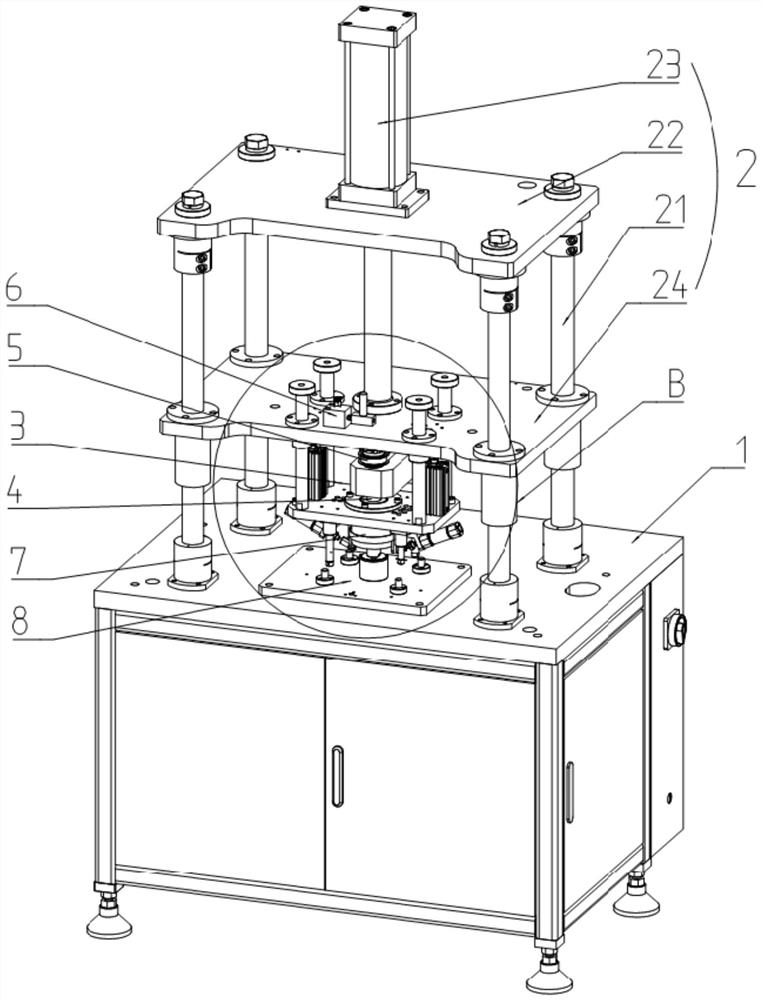

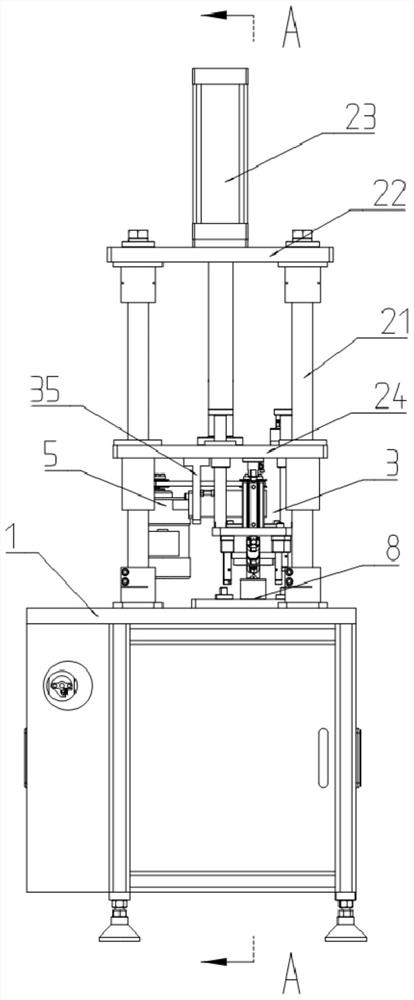

[0041] Reference numerals in the drawings in the description include:

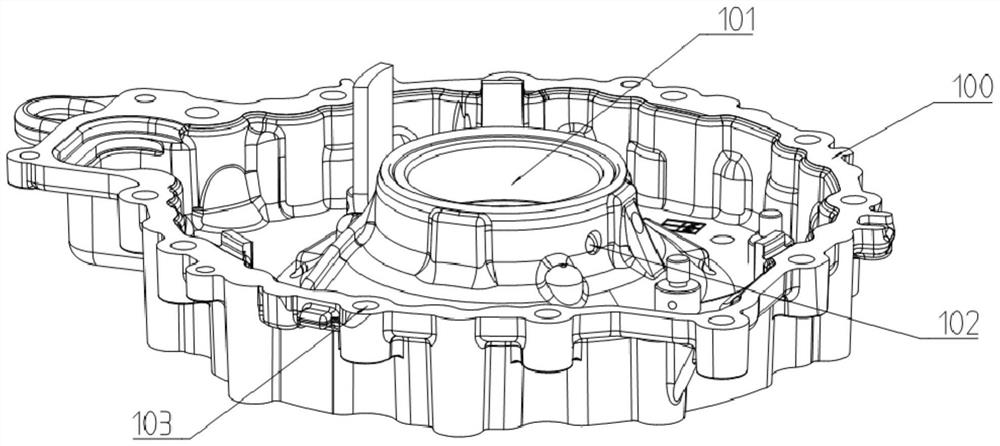

[0042] Parts 100, oiling holes 101, side holes 102, positioning holes 103, frame 1, total drive mechanism 2, column 21, top plate 22, total drive cylinder 23, mounting plate 24, floating pressing part 3, connecting plate 31, Single-acting cylinder 32, guide column 33, limit block 34, support plate 35, transmission hole 351, fuel injection rod 4, oil passage 42, fuel injection hole 43, rotary joint 44, bearing seat 45, bearing 46, rotating device 5 , motor 51, driving wheel 52, belt 53, driven wheel 54, oil supply assembly 6, oil drum 61, oil inlet pipe 62, throttle valve 63, gas-liquid two-phase atomizer 64, oil outlet pipe 65, pressing seat 7 , the first sealing ring 71, the pressure rod 72, the plug 73, the tubular cylinder 74, the working hole 76, the placing seat 8, the blocking column 81, the second sealing ring 82, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com