Anti-corrosion oil coating device for overhead power transmission wires

A coating device and anti-corrosion oil technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of environmental and equipment oil pollution, grease waste, and increased labor costs, and achieve the improvement of anti-corrosion effect and oil coating weight Guarantee and avoid the effect of ointment waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

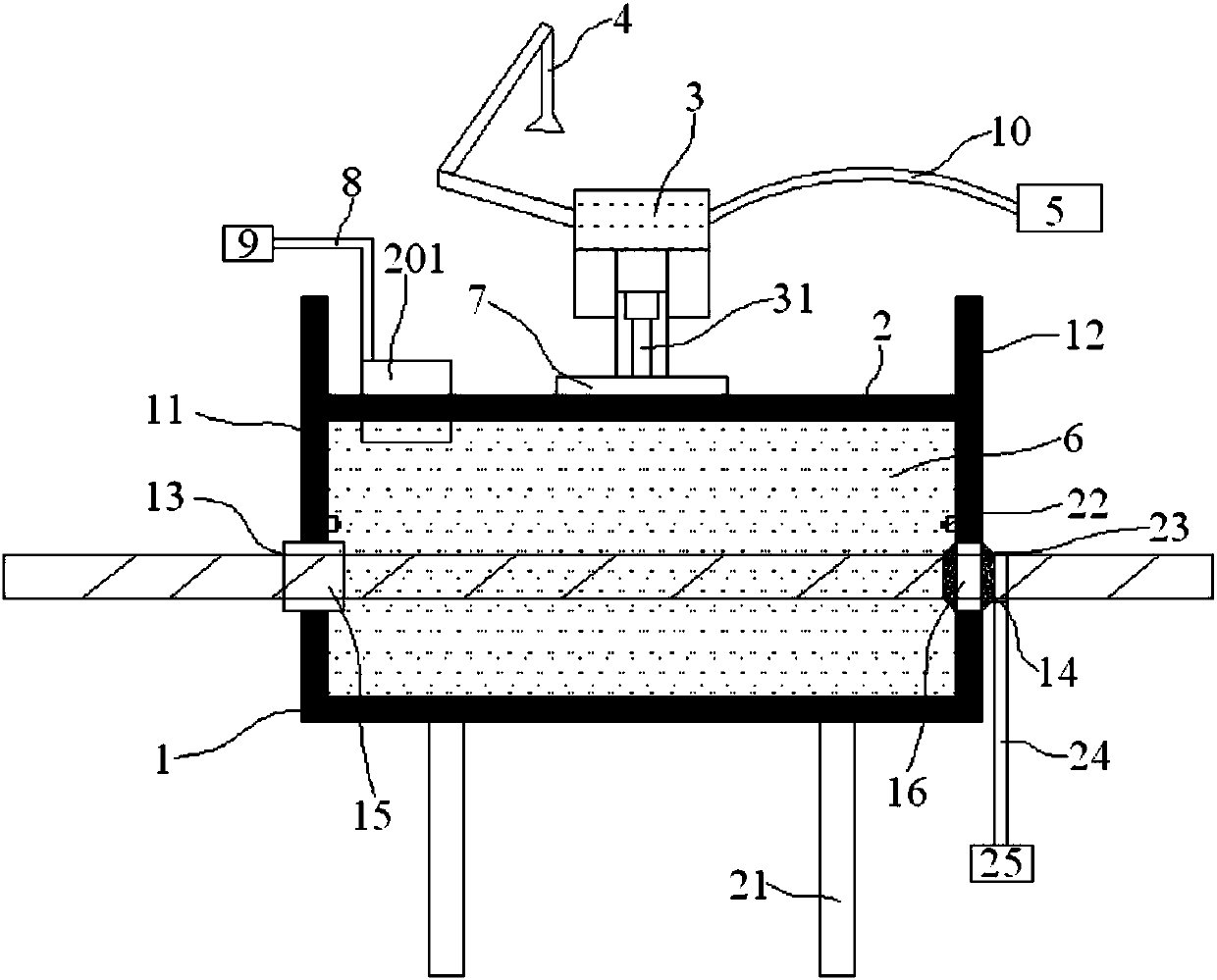

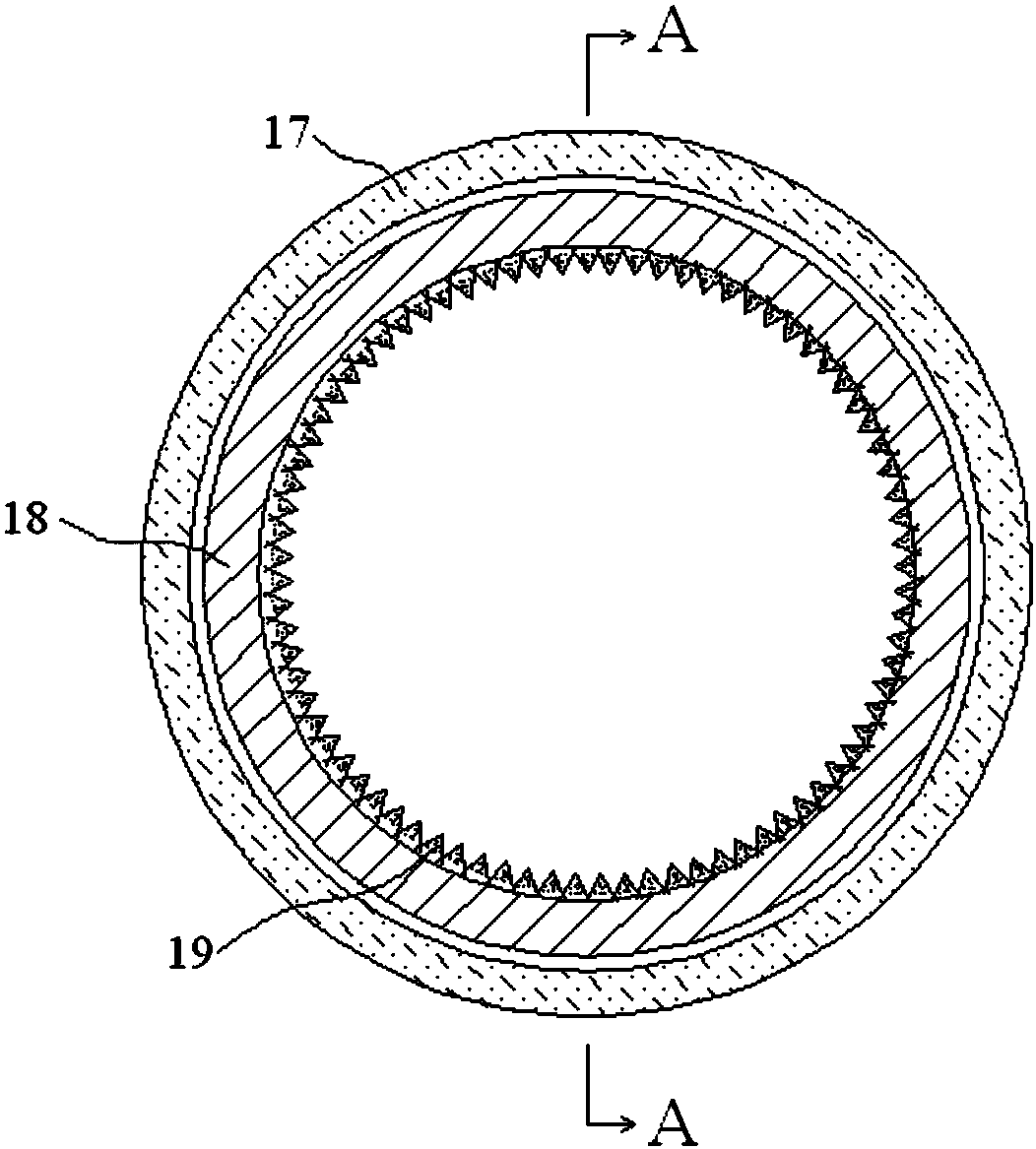

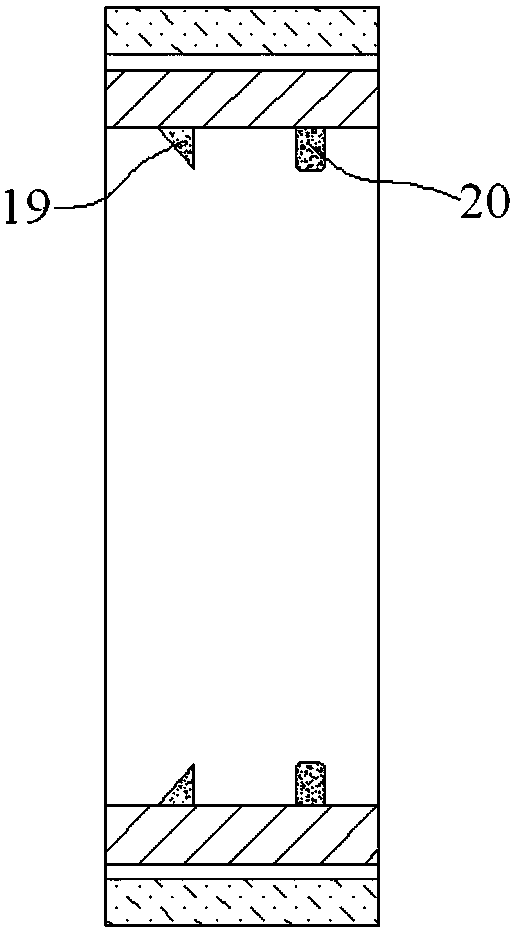

[0019] Embodiment 1: An anti-corrosion oil coating device for overhead power transmission wires, comprising an ointment storage box 1, a movable platen 2, a driving cylinder 3, a cylinder fixing frame 4 and an air compressor 5, the ointment storage box 1 stores ointment 6, the movable platen 2 is movably installed in the ointment storage box 1 and is in close contact with the four walls of the ointment storage box 1, a gasket 7 is fixed on the upper surface of the movable platen 2, and the The end of the piston rod 31 of the driving cylinder 3 is connected to the gasket 7 located on the movable platen 2, and a photosensitive part 22 is installed on the side wall of the ointment storage box 1 and is located between the movable platen 2 and the wire inlet 13 and the wire outlet. Between 14;

[0020] An oil delivery hole is opened on the movable platen 2, and the oil delivery hole is connected to the oil delivery machine 9 through the oil delivery pipe 8, the air compressor 5 and...

Embodiment 2

[0023] Embodiment 2: An anti-corrosion oil coating device for overhead power transmission wires, comprising an ointment storage box 1, a movable platen 2, a driving cylinder 3, a cylinder fixing frame 4 and an air compressor 5, the ointment storage box 1 stores ointment 6, the movable platen 2 is movably installed in the ointment storage box 1 and is in close contact with the four walls of the ointment storage box 1, a gasket 7 is fixed on the upper surface of the movable platen 2, and the The end of the piston rod 31 of the driving cylinder 3 is connected to the gasket 7 located on the movable platen 2, and a photosensitive part 22 is installed on the side wall of the ointment storage box 1 and is located between the movable platen 2 and the wire inlet 13 and the wire outlet. Between 14;

[0024] An oil delivery hole is opened on the movable platen 2, and the oil delivery hole is connected to the oil delivery machine 9 through the oil delivery pipe 8, the air compressor 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com