Automatic oiling device for CD driver screw rod

A driving device and screw technology, applied in the direction of optical recording head, reducing the physical parameters of the carrier, etc., can solve the problems of lubricating oil waste, unable to oil the thread, insufficient lubrication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

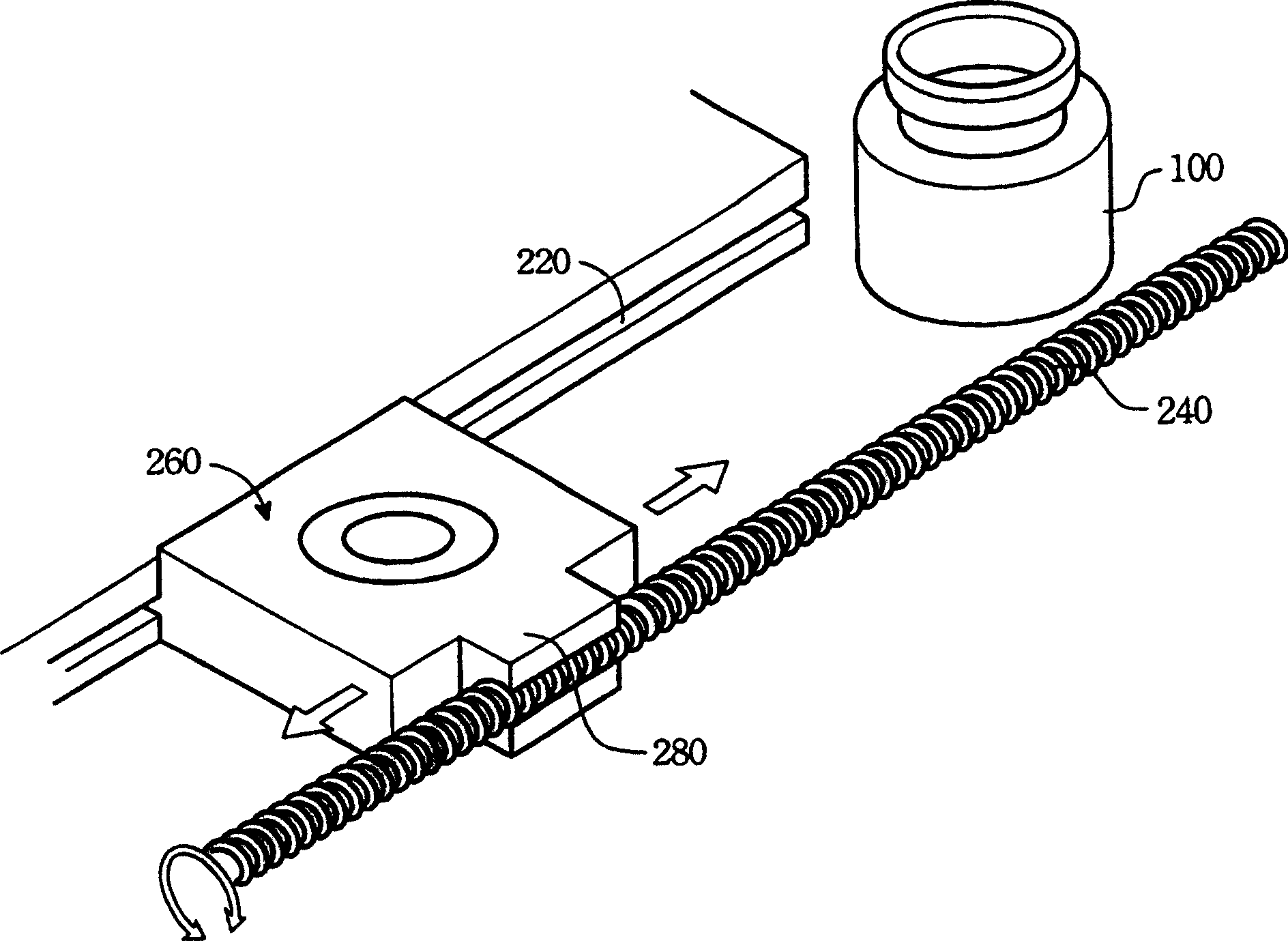

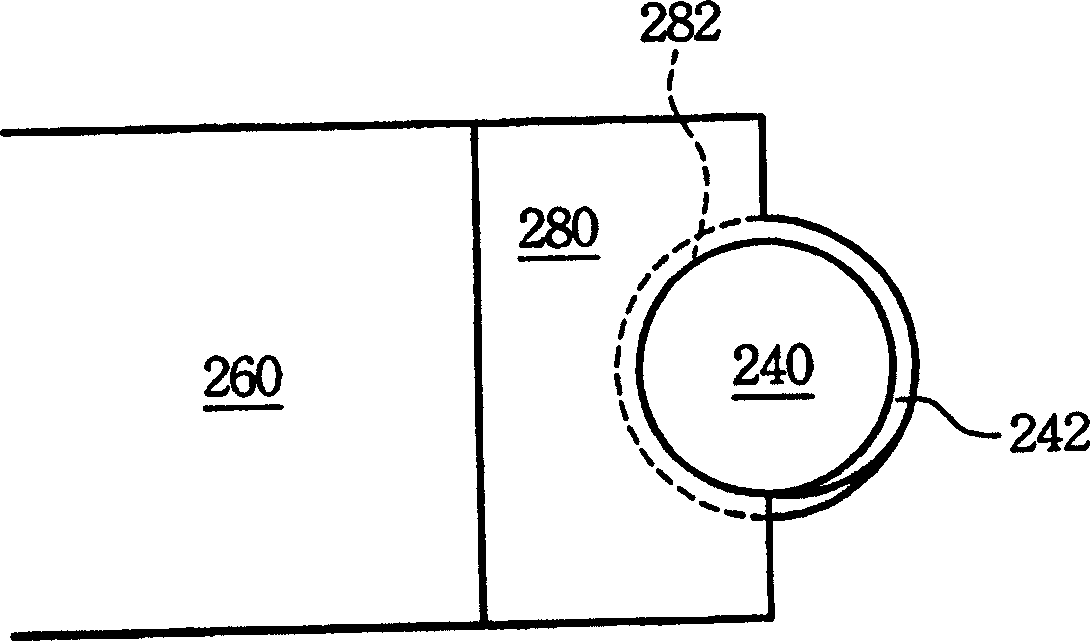

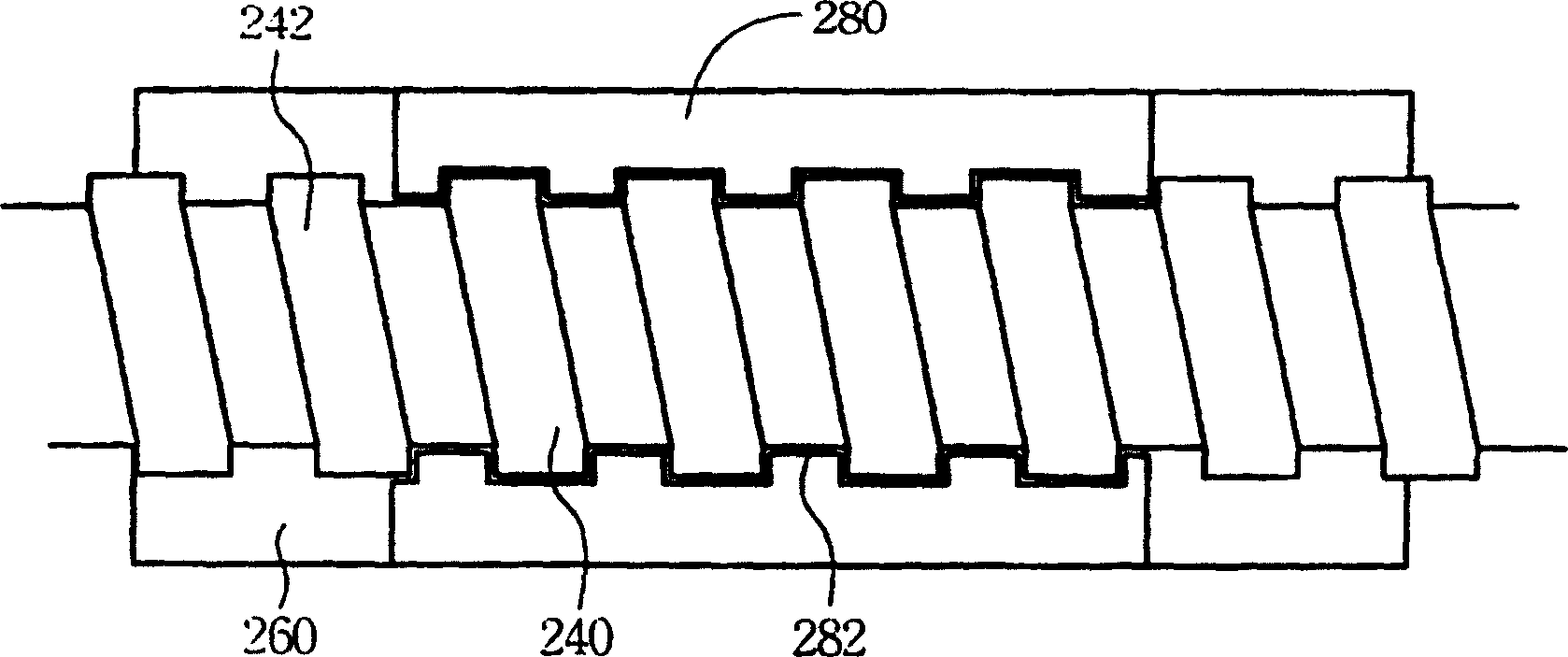

[0023] Please refer to Figure 4 Shown is a schematic diagram of a preferred embodiment of the automatic oiling device 400 of the present invention. The automatic oiling device 400 includes a screw base 420 , a movable driving part 440 and an oil supply 460 . Wherein, the screw seat 420 is used to carry and position the screw 240 to be oiled, and the movable driving part 440 is located above the screw seat 420 to engage with the screw 240 . The oil supply 460 is fixed on the driving part 440 and has an oil injection nozzle 462 extending to the inside of the driving part. When the driving part 440 engages downwardly on the screw rod 240 , the grease nozzle 462 is also aligned with the thread of the screw rod 240 . Subsequently, the driving part moves linearly along the axial direction of the screw rod 240 , drives the screw rod 240 to rotate at the same time, and makes the oil injection nozzle 462 move along the thread of the screw rod 240 to inject oil therein.

[0024] Als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com