Convenient-to-use steel pipe oiling device

An oiling device and steel pipe technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of time-consuming, laborious, low degree of automation, and unsatisfactory oiling method, and achieve effective cooperation and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

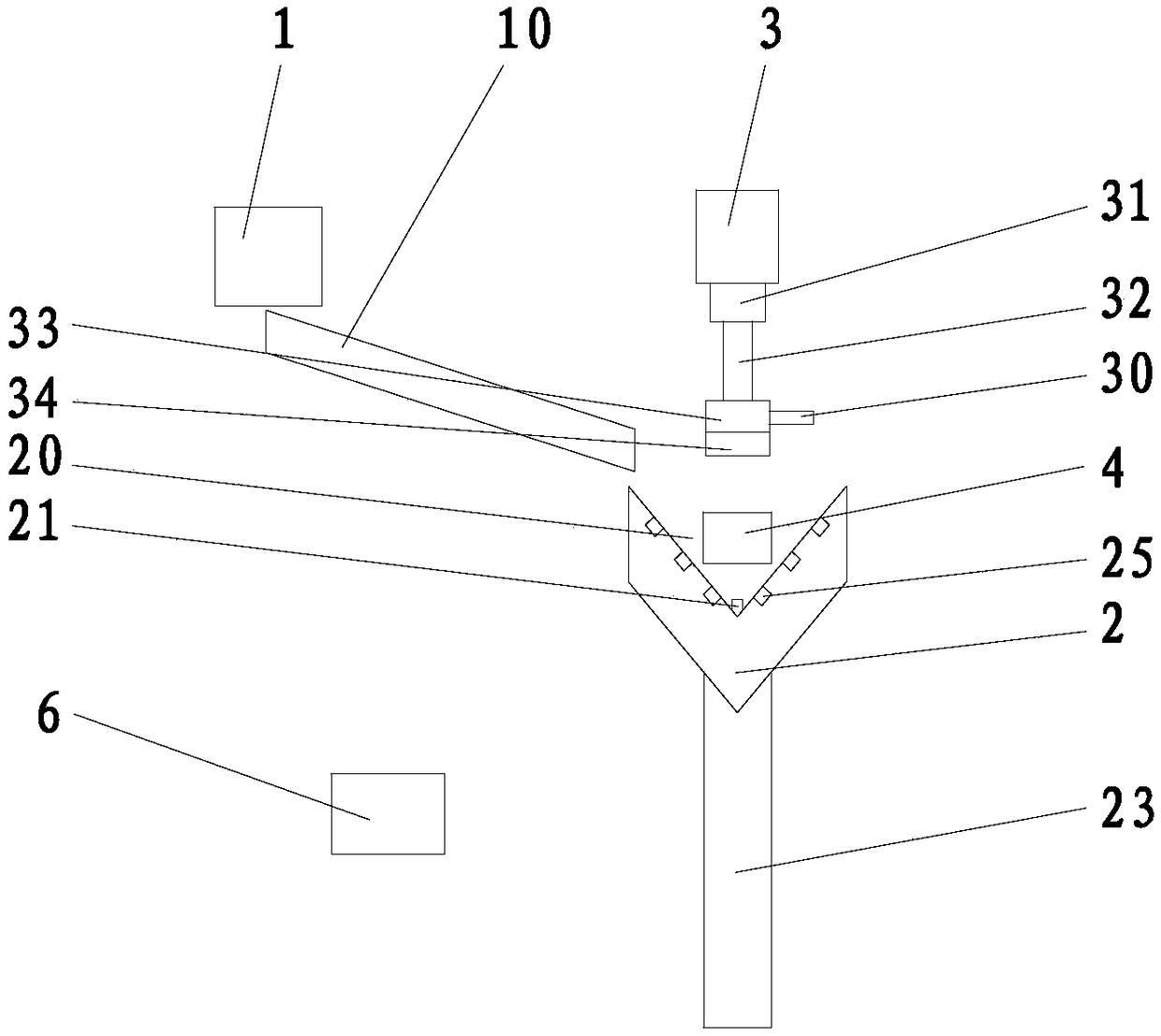

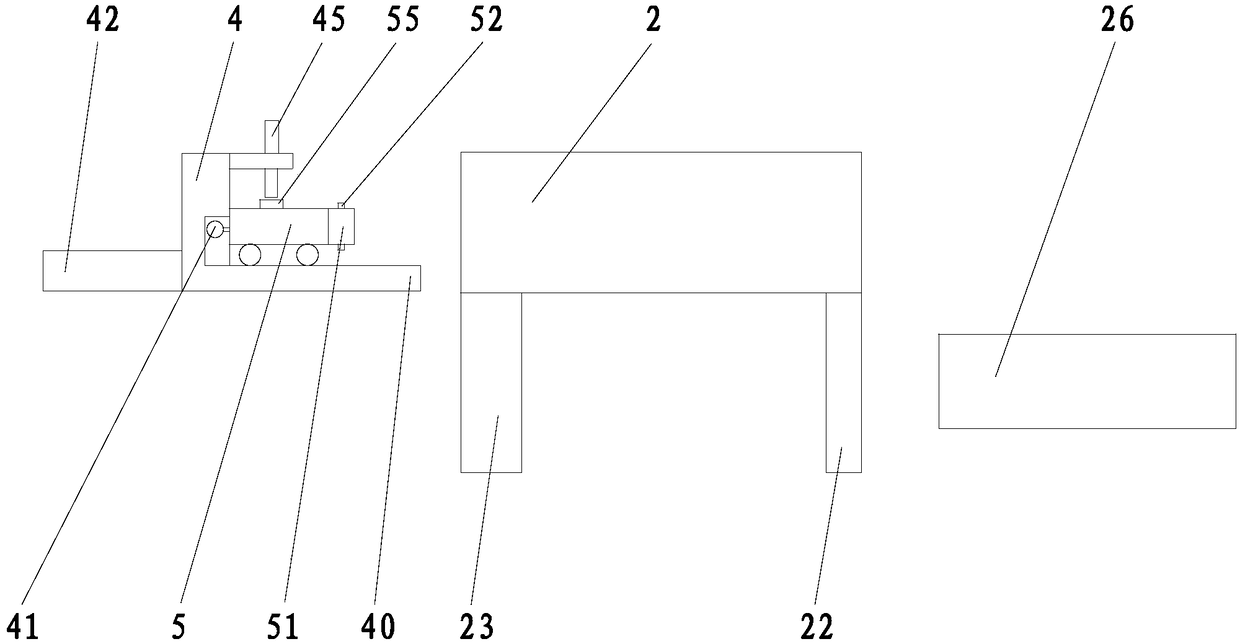

[0017] refer to figure 1 and figure 2 , an easy-to-use steel pipe oiling device of the present invention, comprising a material transport mechanism 1, a guide plate 10, an oiling tank body 2, a support rod 22, a lifting mechanism 23, a push-pull mechanism 42, a fuel injection vehicle 5, a parking platform 40, a blocking Block 4, guide rail 3, telescopic rod 32, oiling brush 34, control device 6, the feed end of described guide plate 10 is matched with a feeding mechanism 1, and guide plate 10 is from feed end to discharge end to Downwardly inclined, an oiling tank body 2 is provided below the discharge end of the guide plate 10. The oiling tank body 2 is in the shape of a strip. V-shaped groove 20, the bottom of V-shaped groove 20 is provided with some spray nozzles 21 that spray oil upwards, and a guide rail 3 parallel to the upper oil tank body 2 is provided on the top of the oil tank body 2, and a guide rail 3 is installed at the bottom of the guide rail 3. The mobile mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com