Skylight frame verticality corrector

A technology of verticality and corrector, which is applied in the direction of skylight/dome, building, building structure, etc., can solve the problems of construction workers such as high labor intensity, difficult operation, large error, etc., and achieve obvious economic and quality effects, installation Convenience and small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

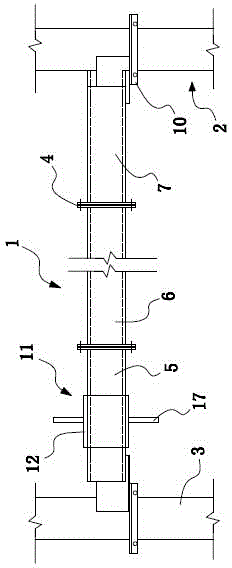

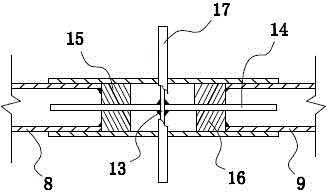

[0018] Such as figure 1 , 2 As shown, a skylight frame verticality corrector includes a correction beam 1, the two ends of the correction beam 1 are respectively connected to the columns 3 of the skylight frames 2 on both sides, and the correction beam 1 includes left sides connected to each other through flanges 4 Crossbeam 5, middle part crossbeam 6 and right side crossbeam 7, left side crossbeam 5, middle part crossbeam 6 and right side crossbeam 7 are all made of Φ43 steel pipe. Wherein, the middle beam 6 can be made into a standard section, which can be assembled and adjusted according to the spacing of the skylight frame. The left crossbeam 5 is composed of a first moving part 8 and a second moving part 9 that can expand and contract to the left and right sides respectively. The column 3 is detachably fixedly connected. On the left side beam 5 of the correction beam 1 , near the end position connected to the skylight frame 2 , an adjustment device 11 for adjusting the...

Embodiment 2

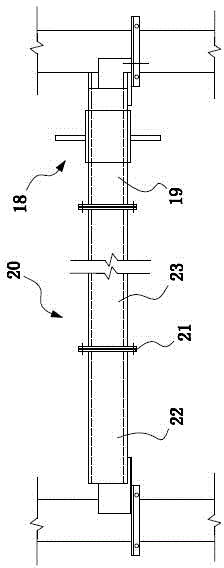

[0021] Such as image 3 , 4 As shown, the same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is that the adjustment device 18 can also be arranged on the right side beam 19, and the correction beam 20 includes left sides connected to each other through flanges 21. Crossbeam 22, middle crossbeam 23 and right side crossbeam 19, described right side crossbeam 19 is made up of the 3rd moving part 24, the 4th moving part 25 that can expand and contract respectively to left side and right side, and adjusting device 18 is located at the 3rd moving part. Part 24, the fourth moving part 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com