An annular stacking three-dimensional garage access trolley

A three-dimensional garage and car technology, which is applied to the buildings, building types, buildings, etc. where cars are parked, can solve the problems of easy slippage of the wire rope, insufficient translation, and accurate hearing of the parking space by the vehicle, so as to improve the stability and service life. , The effect of reducing the requirements for moving vehicles proficiency and reducing the waiting time for parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

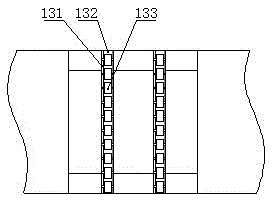

[0048] Four guide posts and guide sleeve support assemblies distributed in an array are in groups of two; the gear transmission mechanism consists of an inter-group transmission mechanism 44 that synchronously drives the movement of the vertical guide posts between the groups and an intra-group transmission that synchronously drives the actions of the vertical guide posts in each group. mechanism 45; that is, the inter-group transmission mechanism 44 can drive the vertical guide pillars 42a, 42b to rise and fall synchronously under the drive of the jacking drive motor 43, and the transmission mechanisms 45 in the two groups respectively drive the vertical guide pillars 42a, 42c to rise and fall synchronously and drive The vertical guide columns 42b, 42d are lifted and lowered synchronously.

[0049] Such as Figure 8 , 9 , 10, in this embodiment, the transmission mechanism 45 in the group includes the output shaft 451 in the group, the transition shaft 452, the output gear 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com