Door lock latch bolt drive mechanism

A drive mechanism and oblique tongue technology, applied in building locks, building structures, buildings, etc., can solve problems such as loud noise and discomfort, reduce collision noise, retract and extend slowly and smoothly, and open and close silently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be implemented in the following ways:

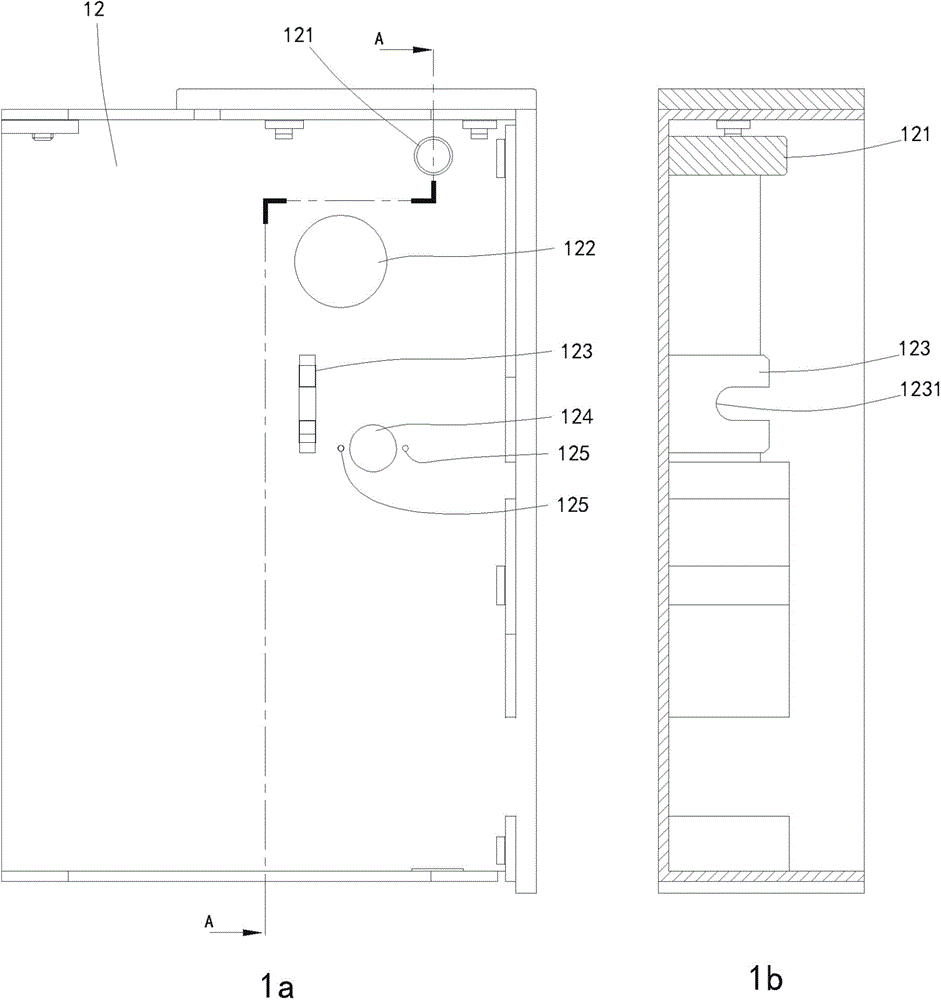

[0022] Such as figure 1 Shown: the upper right corner of the bottom plate 12 of the present invention is provided with a positioning column 121, a dial hole 122, a bracket 123 is provided in the middle, a sliding groove 1231 is provided at the upper end of the bracket, and a rotation damper positioning hole is provided on the right side of the bracket 123 124 and screw holes 125.

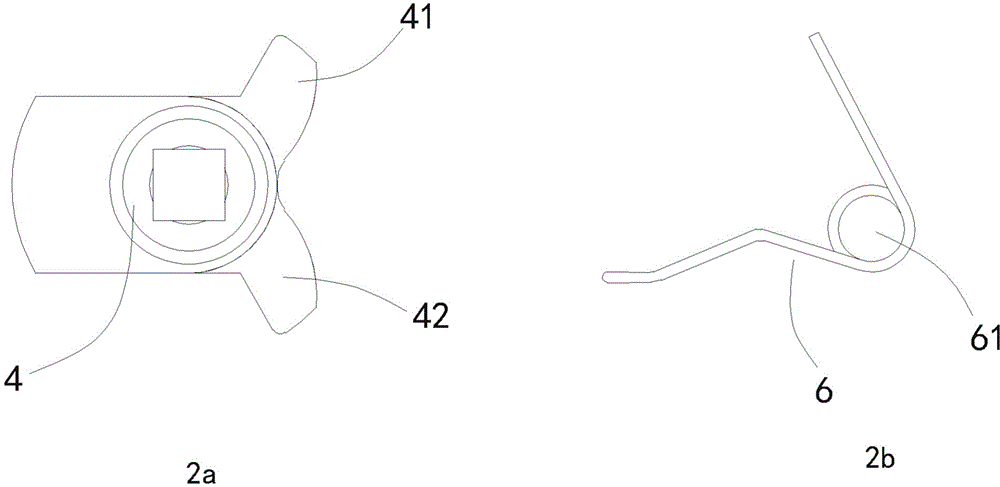

[0023] Such as figure 2 Shown: the peach dial 4 side of the present invention is provided with a claw A41 and a claw B42; peach dial torsion spring 6 is provided with a positioning ring 61.

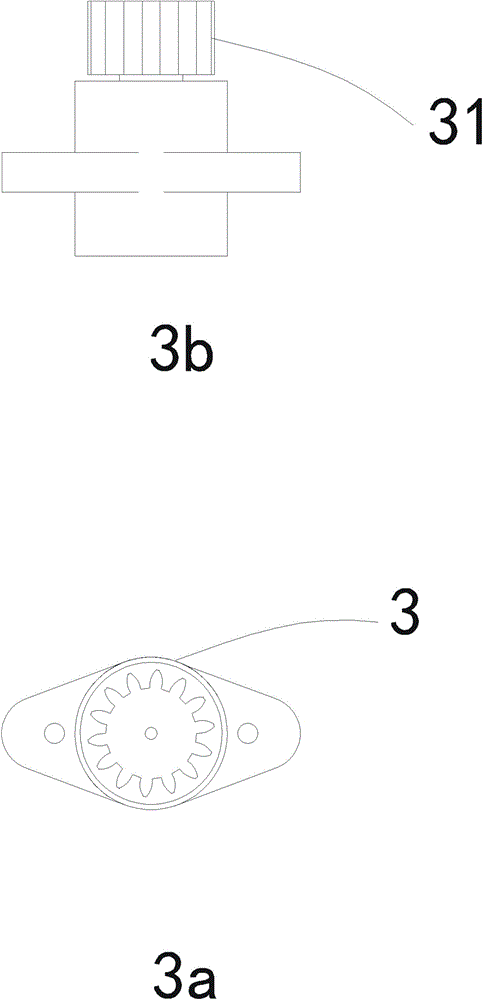

[0024] Such as image 3 Shown: the front end of the rotary damper 3 of the present invention is provided with a damping gear 31.

[0025] Such as Figure 4 As shown: one end of the tilt tongue toggle plate 5 of the present invention is provided with a toggle claw 51 , the other end is provided with a through hole 52 , and the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com