Locking-type glass door lock

A glass door lock, locking technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problems of deformation and fracture of positioning columns, loss of anti-theft function, poor strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

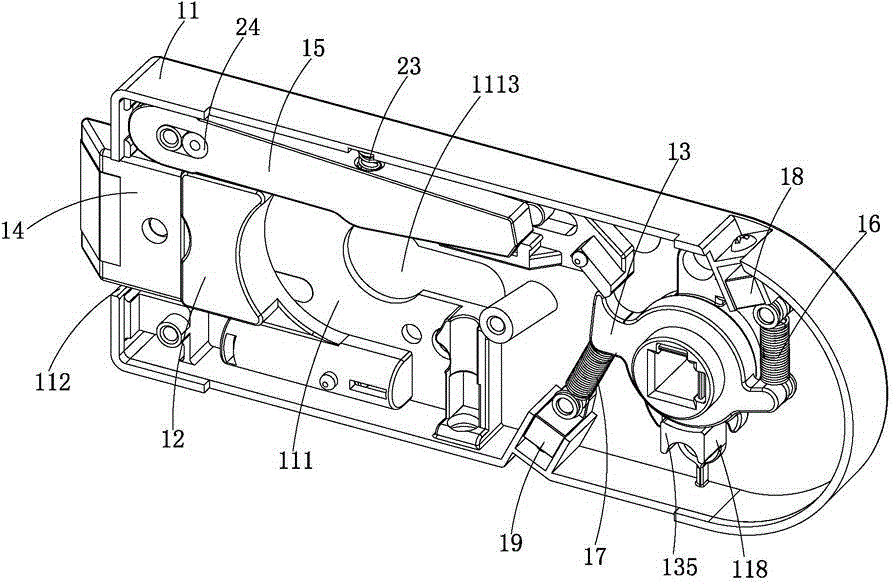

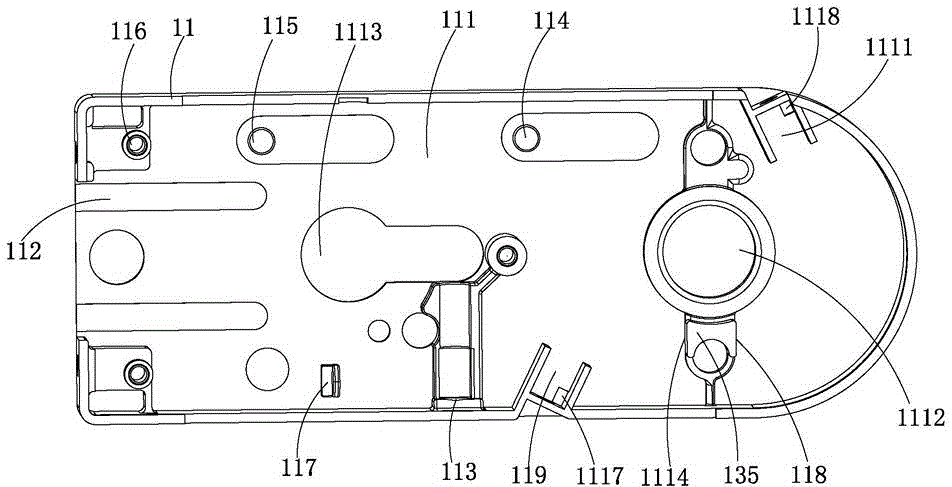

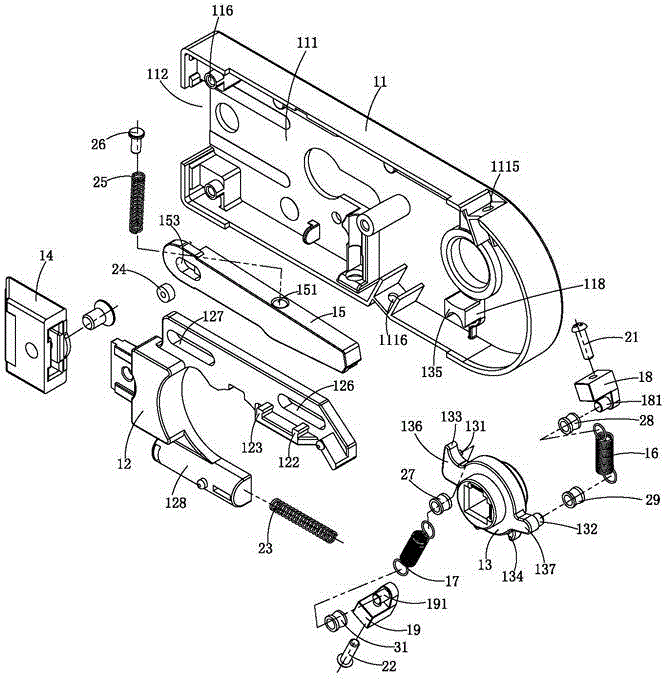

[0042] see Figure 1-Figure 8 As shown, a locking type glass door lock is mainly composed of a lock body 11, a gland 32, a deadbolt movement mechanism installed in the lock body 11, a torsion wheel 13 and its first tension spring reset device, and the second tension spring reset. Device, positioning rod 15 and lock tube 41 form. The dead bolt movement mechanism comprises dead bolt 14, slide block 12, the 1st positioning post 114 and the 2nd positioning post 115, and dead bolt 14 is fixed on the front end of slide block 12, and the first guide groove 126 of slide block 12 and the 2nd guide groove 127 are matched and slidably connected with the first positioning column 114 and the second positioning column 115 fixed in the lock body 11 respectively, and the dead bolt 14 is located at the front end portion of the lock body 11 at the edge lock opening 112 . The shaft of the twist wheel 13 is installed in the first shaft hole 1112 on the lock body 11 and the second shaft hole 321 ...

Embodiment 2

[0061] see Figure 9 , Figure 10As shown, the structure of the lockable glass door lock of this embodiment is basically the same as that of the lockable glass door lock of Embodiment 1, the difference is that the first guide groove 126 and the second guide groove of the slider 12 Between 127 there is also a seventh positioning post 120 recessed in the plane of the main body of the slider 12 and a pipe-shaped groove 1213 recessed in the main body of the slider 12 , the seventh positioning post 120 is located in the center of the pipe portion of the pipe-shaped recess 1213 . The front end of the seventh positioning column 120 is provided with a fifth overlapping surface 1202 , and the rear end of the seventh positioning column 120 is provided with a sixth overlapping surface 1201 .

[0062] The 8th positioning post 150 that protrudes is provided with the 8th positioning post 150 that protrudes in the center of the positioning rod 15 main body between the 5th positioning post 1...

Embodiment 3

[0072] see Figure 11 , Figure 12 As shown, the structure of the lockable glass door lock of this embodiment is basically the same as that of the lockable glass door lock of Embodiment 2, except that the sixth overlapping surface 1201 of the seventh positioning post 120 of the slider 12 The 3rd semicircle positioning groove 1203 is added in the lower part of the locating bar 15, and the 3rd front 1502 lower part of the 8th positioning column 150 of the positioning rod 15 is additionally provided with the 3rd semicircle positioning column 1503. catch. In the closed state, the third semicircular positioning column 1503 is hooked with the third semicircular positioning groove 1203 to prevent the positioning rod 15 from dislocating and moving outward when the deadbolt 14 is subjected to a strong external force and loses the positioning and locking function.

[0073] In general, the lock-type glass door lock of embodiment 3 has the most powerful locking function, followed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com