Electric shuttle valve of cam mechanism

A technology of electric shuttle valve and cam mechanism, which is applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of inability to meet the cleanliness requirements of the aerospace gas system, the decrease of sealing performance, and the wear of gaskets, etc., and achieve simple structure , reduce the driving torque, reduce the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

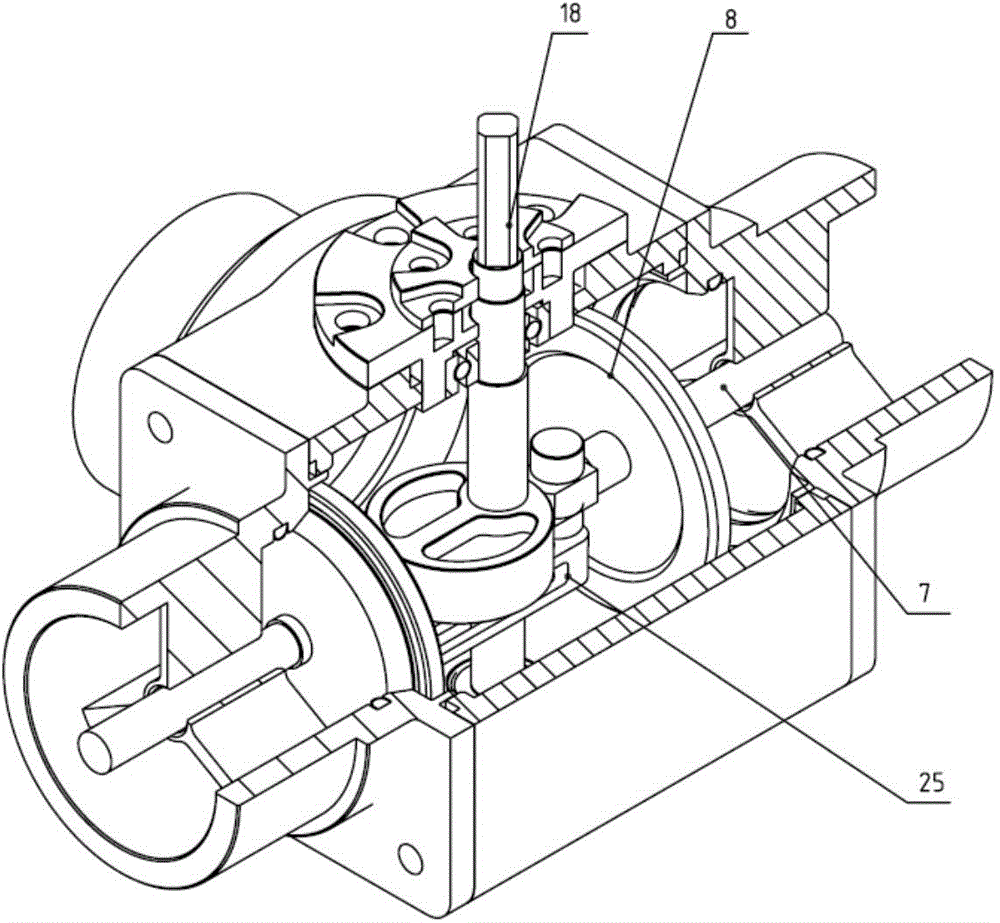

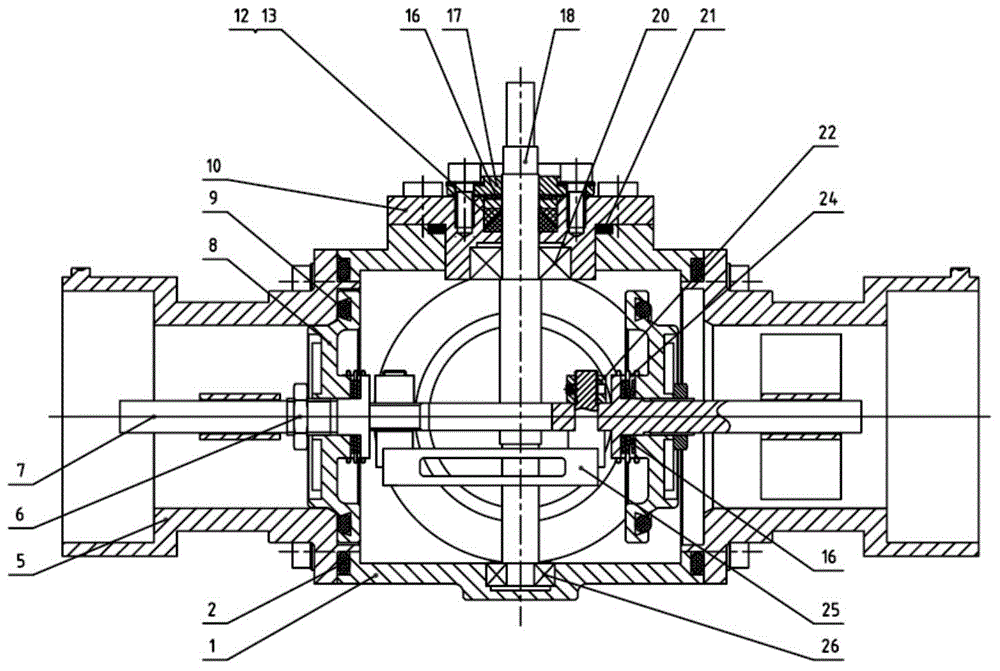

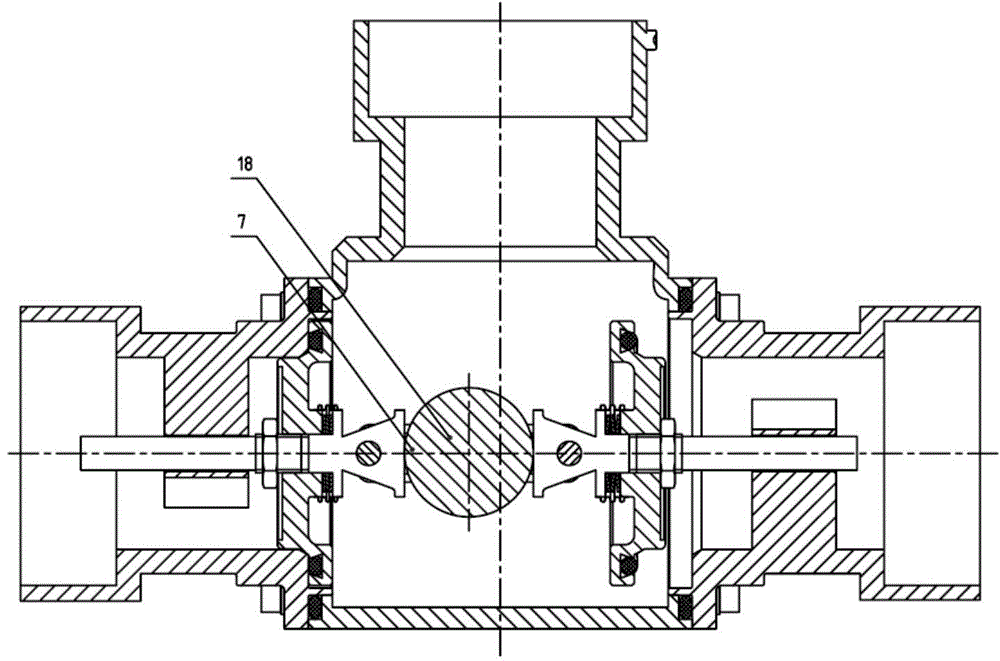

[0019] Such as figure 1 As shown, the electric shuttle valve of the present invention consists of a three-way valve body 1, a first sealing ring 2, a flange end cover 5, an M8 thin nut 6, a guide rod 7, a valve core 8, a second sealing ring 9, and a sealing gland 10. First sealing packing 12, second sealing packing 13, disc spring 16, upper gland 17, valve stem 18, first bearing 20, third sealing ring 21, fixing ring 22, bellows 24, connecting frame 25, The second bearing 26 is formed. The flange end cover 5 and the first sealing ring 2 are installed on the three-way valve body 1 (left and right); the sealing gland 10, the second sealing ring 21 and the first bearing 20 are installed on the three-way valve body 1 (top); the first sealing packing 12, the second sealing packing 13, the disc spring 16, and the upper gland 17 are installed on the three-way valve body 1 (top, between the sealing gland 10 and the first bearing 20); bellows 24 is welded as one with guide rod 7, spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com