Valve and engine-driven generator

An engine drive and generator technology, applied in the direction of engine components, functional valve types, safety valves, etc., can solve problems such as high cost and complex structure of one-way valves, reduce assembly difficulty and machining accuracy requirements, and simplify valve structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

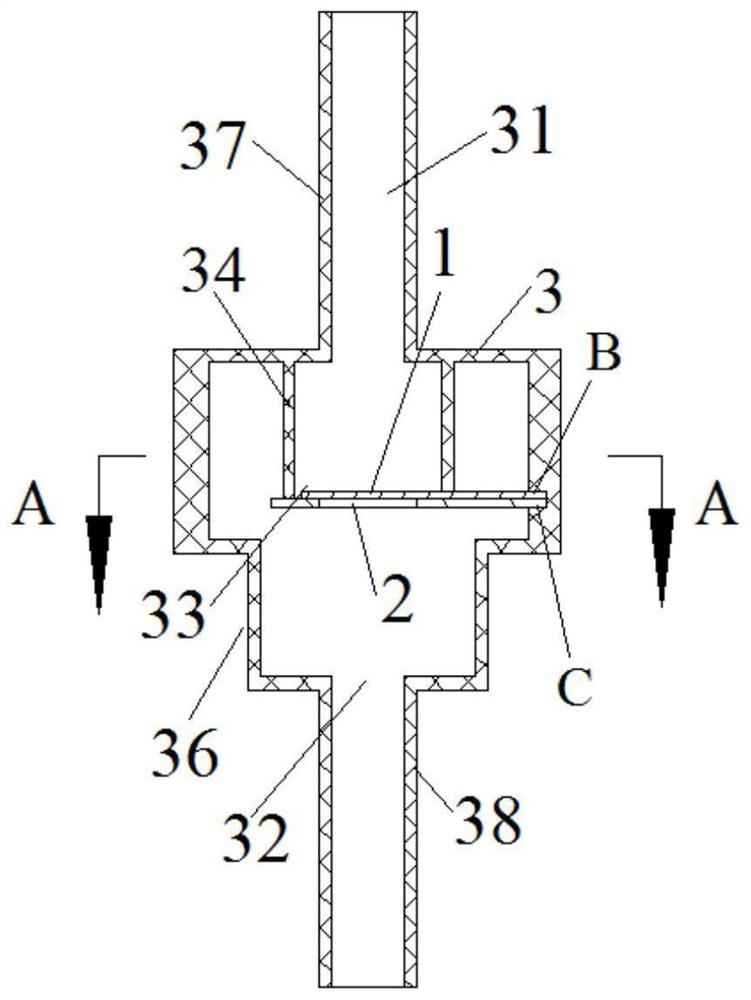

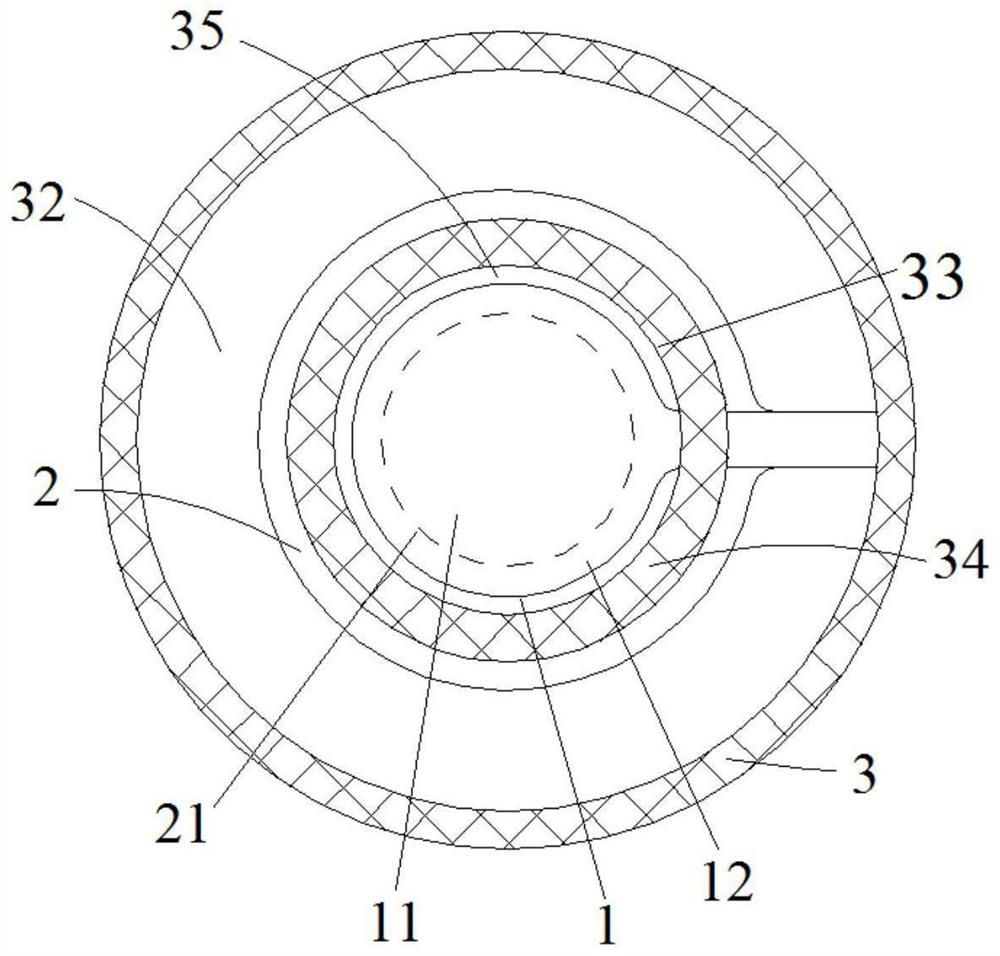

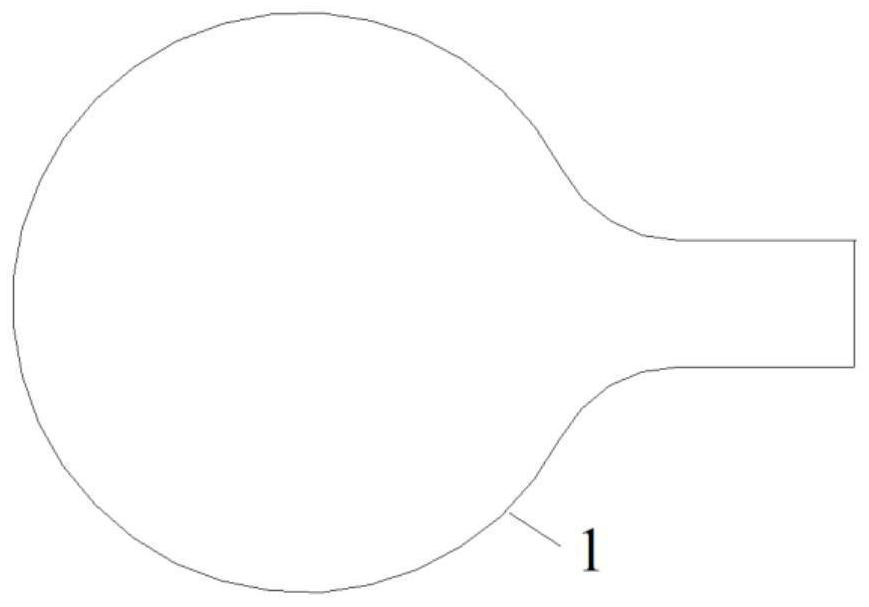

[0048] Embodiment 1 of the valve provided by the present invention is applied to the fuel tank ventilation pipeline of the engine-driven generator. The valve specifically includes a valve body 3 , and a first chamber 31 and a second chamber 32 are disposed through the valve body 3 . Inside the valve body 3, the first chamber 31 is docked with the second chamber 32, and the first valve plate 1 with elasticity and the second valve plate 2 with elasticity are arranged at the interface 33, specifically, the first valve plate 1 and the second valve plate 2 are reeds. Wherein, the first chamber 31 and the second valve plate 2 are respectively located on two sides of the first valve plate 1 .

[0049] Since the first valve piece 1 and the second valve piece 2 have elasticity, during the working process, according to the pressure difference on both sides of the docking port 33, the first valve piece 1 and the second valve piece 2 are adaptively deformed, thereby changing the first va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com