Efficient centrifugal dehydrator

A centrifugal dehydrator, a high-efficiency technology, is used in drying solid materials, drying solid materials without heating, lighting and heating equipment, etc. problem, to achieve the effect of convenient use, simple structure and fast dehydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

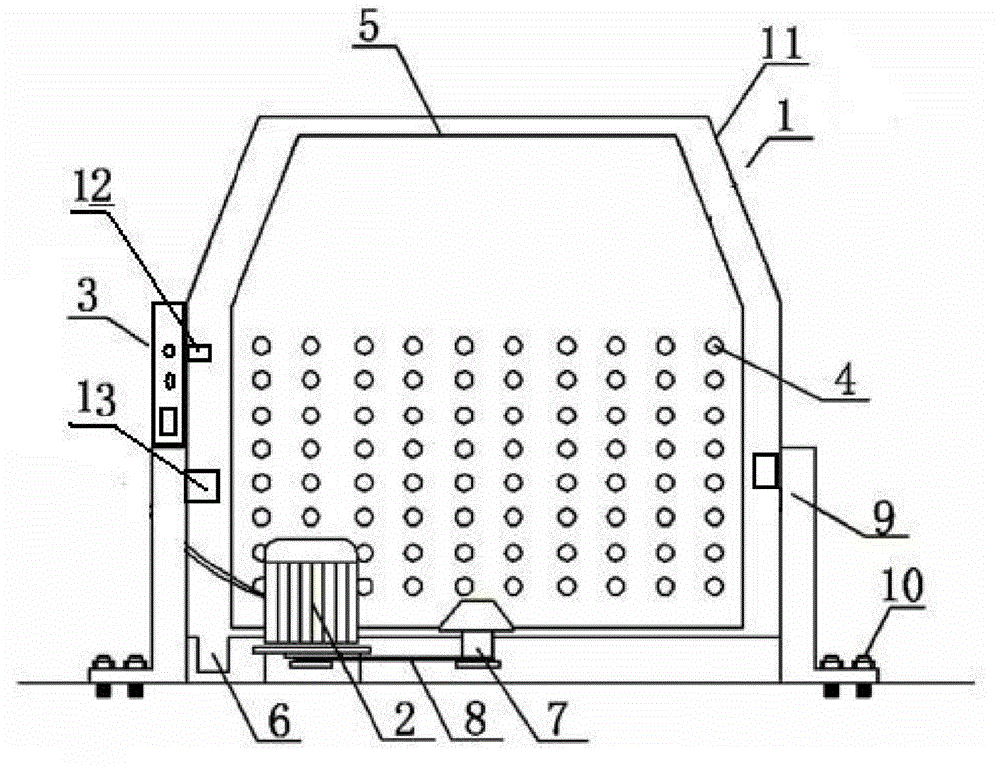

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0011] like figure 1 As shown, a high-efficiency centrifugal dehydrator includes: a cylindrical barrel body 1, a frequency conversion motor 2, a deflection adjustment bracket 13, and a control panel 3. The inner side of the cylindrical barrel body 1 is provided with a barrel inner liner 11. The tank 11 is provided with a number of water removal holes 4, the top of the cylindrical barrel body 1 is provided with a feed port 5, the lower end of the cylindrical barrel body 1 is provided with a drain port 6, and a rotating shaft is fixed at the center of the bottom of the barrel body 11. 7. The rotating shaft 7 is connected to the variable frequency motor 2 through the transmission chain 8; the cylindrical barrel body 1 is fixed with several fixing plates 9, and the fixing plates 9 are provided with thre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap