Loading device and method for material double-shaft compression test

A compression test and compression device technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of complexity, limitation, and high cost in actual implementation, and achieve the effects of easy processing and maintenance, uniform load distribution, and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

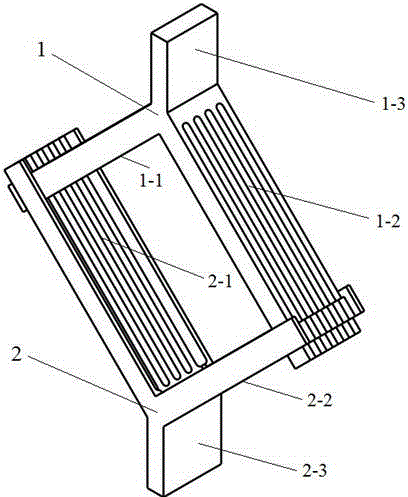

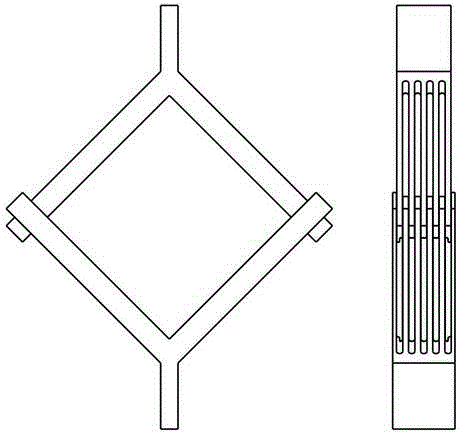

[0024] A loading device for biaxial compression test of materials, its structure is as follows figure 1 , figure 2 As shown, the device is composed of an upper Y-type compression device 1 and a lower Y-type compression device 2 .

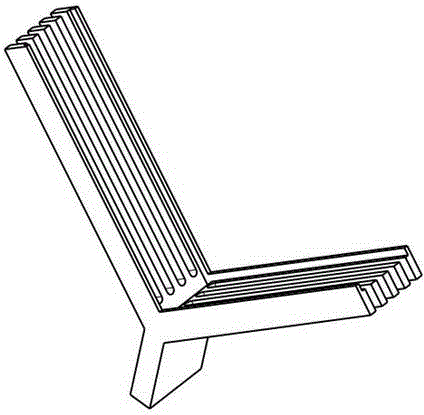

[0025] like image 3 As shown, the upper Y-shaped compression device 1 is composed of a first loading arm 1-1, a second loading arm 1-2 and a top clamping end 1-3, wherein the first loading arm 1-1, the second loading arm 1- 2 form a right angle between them, and the top clamping end 1-3 is located on the bisector of the right angle; the above-mentioned first loading arm 1-1 has a number of guide grooves parallel to each other from front to back, and the guide groove connects the first loading arm 1-1 is divided into several loading arm branches; the above-mentioned second loading arm 1-2 is provided with several mutually parallel guide grooves from front to back, and the guide grooves divide the second loading arm 1-2 into several loading arm br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com