Experimental device for rubber cylinder of compression packer

A compression packer and experimental device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of scrapping packer prototypes, time-consuming and high experimental costs, and achieve the effect of saving experimental costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

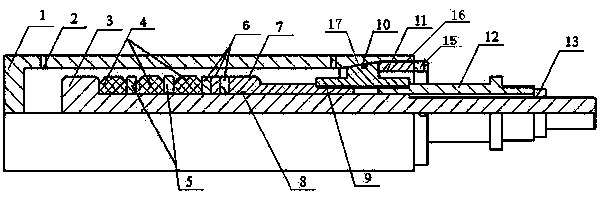

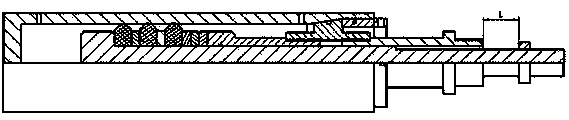

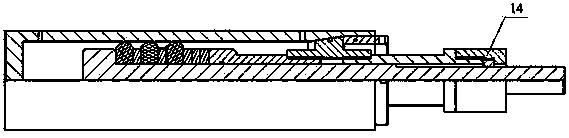

[0024] In order to overcome the problem that in the existing compression packer rubber cartridge experiment, a set of packer prototypes should be scrapped for each experiment, the experiment cost is high, and the problem of time-consuming is long, this embodiment provides a method such as figure 1 , figure 2 and image 3 The compression packer rubber cylinder experimental device shown includes a pressure-bearing cylinder 1, a mandrel 3, an upper joint 7, a hanger 9, and an extension cylinder 12. The pressure-bearing cylinder 1 is a circle with a closed lower end and an open upper end. The cylinder body, the side of the outer wall of the pressure-bearing cylinder 1 is provided with a liquid inlet hole 2, the mandrel 3 is placed in the pressure-bearing cylinder 1, the outer wall of the mandrel 3 is sleeved with a rubber cylinder 4 and an upper joint 7, The upper end of the rubber tube 4 is separated from the lower end of the upper joint 7 by a spacer 26, and the upper end of t...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 As shown, the assembly process of the compression packer rubber cartridge experimental device of the present invention is as follows: the rubber cartridge 4 of the compression packer and the spacer ring-5 are as follows figure 1 Put them on the mandrel 3 in turn, the number of rubber tubes 4 and spacer 1 can be changed; then connect the upper joint 7, the hanger 9, and the extension tube 12 with threads, put them on the mandrel 3, and tighten the pressure ring 13. Make the rubber tube 4 and the spacer ring 5 closely fit, but the rubber tube 4 is not compressed; then put the assembled mandrel 3 into the pressure-bearing tube 1, make the tapered surface of the hanger 9 and Fit the conical surface of the pressure-bearing cylinder 1, and tighten the top cap 11; finally, connect the liquid inlet 2 to the corresponding high-pressure pipeline.

[0035] Such as figure 1 As shown in the assembled experimental device, the high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com