Method for optimizing integrated scheduling of multiple energy mediums of iron and steel enterprise

A medium integration, multi-energy technology, applied in data processing applications, forecasting, computing and other directions, can solve the problem of lack of multi-energy medium integration scheduling optimization methods, etc., to make full use of secondary energy, reduce blind production, and clear guiding significance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

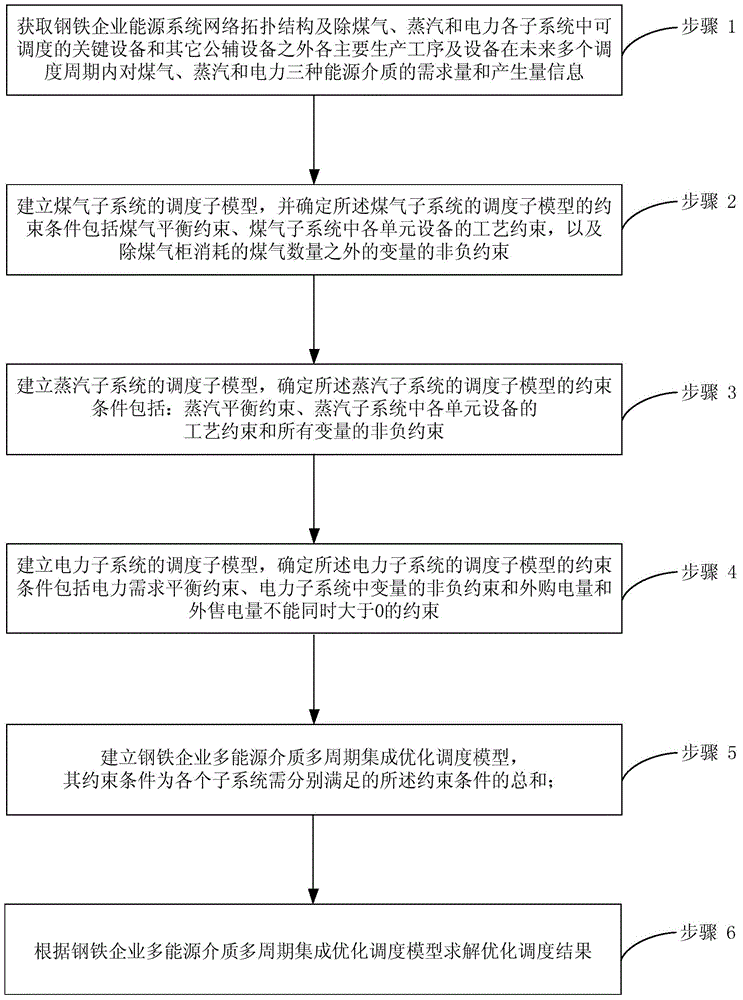

[0048] In the iron and steel enterprise multi-energy medium integrated scheduling optimization method provided by the embodiment of the present invention,

[0049] The network topology of the energy system of iron and steel enterprises obtained in step 1 includes: various energy medium pipe network information, and unit equipment information such as schedulable key equipment and other public and auxiliary equipment in the gas, steam, and electric subsystems.

[0050] In step 2:

[0051] Min J 1 = pun emi gas - pro gas = Σ t Σ j ∈ EMI Σ i ∈ GAS p i emi · x ...

Embodiment 2

[0114] Embodiment 2 provided by the present invention is a specific application embodiment of a multi-energy medium integrated scheduling optimization method for iron and steel enterprises provided by the present invention.

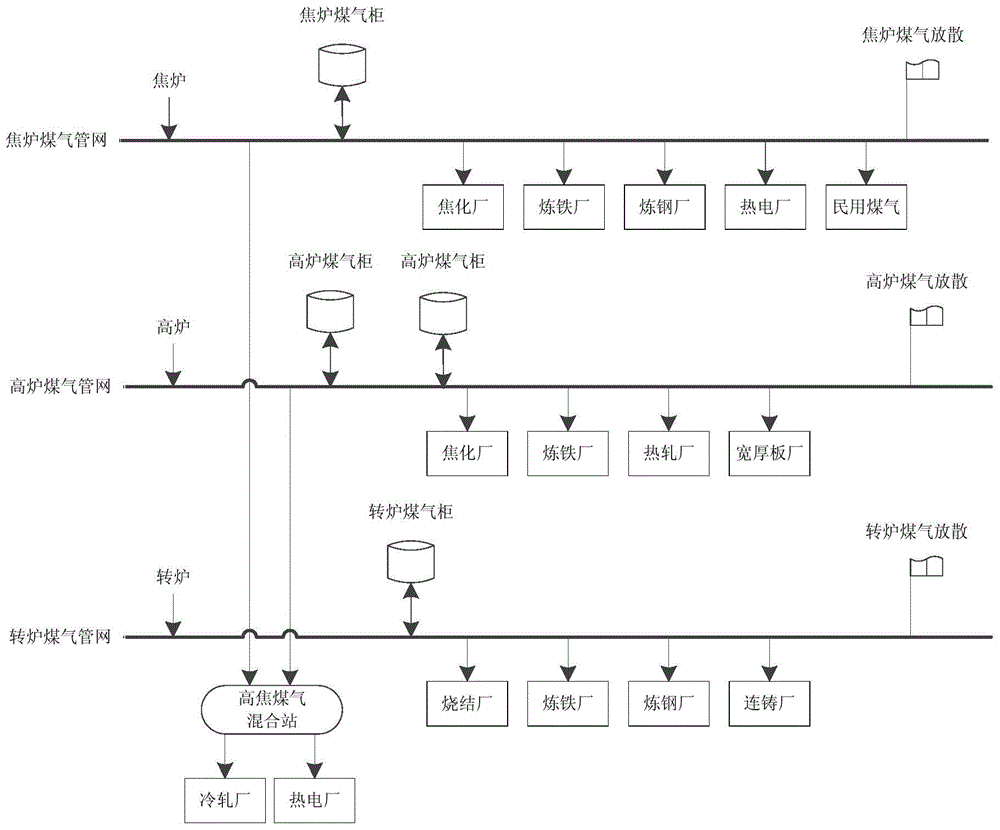

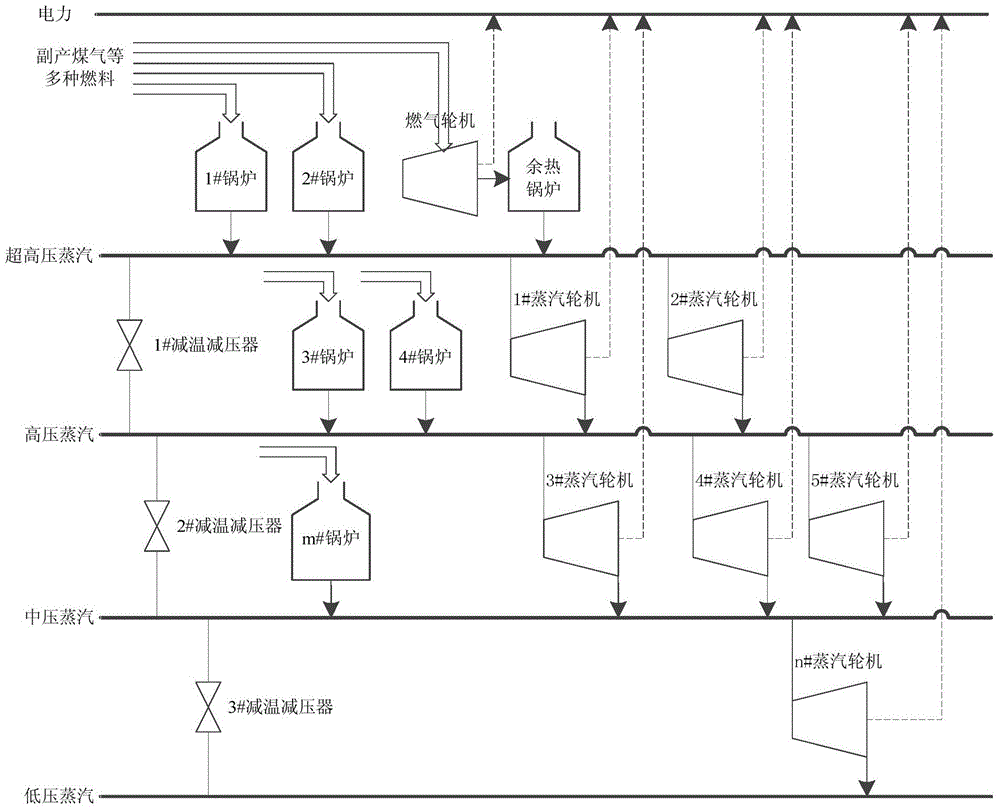

[0115] Take a large-scale full-process iron and steel complex as an example. figure 2 It is the topological structure diagram of the gas subsystem of a typical iron and steel enterprise, image 3 It is a topology diagram of the steam and power subsystem of a typical iron and steel enterprise. Depend on figure 2 It can be seen that the main by-product gases of iron and steel enterprises are blast furnace gas (BFG), coke oven gas (COG) and converter gas (LDG), which are produced by blast furnace, coke oven and converter respectively. The main network of various gas media is equipped with corresponding gas cabinets and release towers, and the main production process users, such as ironworks, steelworks and wide and heavy plate factories, are also connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com