Condensing unit for vacuum oil purifier

A technology of vacuum oil purifier and condensing device, which is applied in the direction of steam condensation, fixed filter element filter, filtration and separation, etc. It can solve the problems of poor working efficiency and purification effect, time-consuming and labor-intensive, and affecting efficiency, etc., to improve the net Oil effect, increase safety performance, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

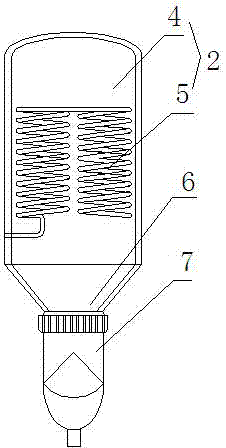

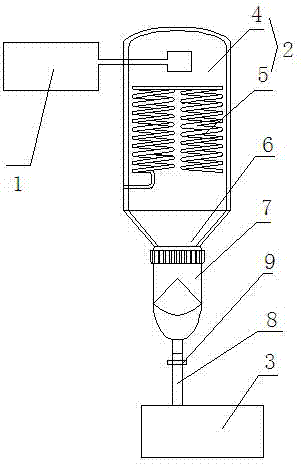

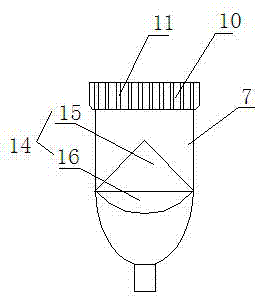

[0017] As shown in the figure, a condensing device for a vacuum oil purifier is used on a vacuum oil purifier. The vacuum oil purifier includes an atomization device 1, a condensing device 2 and a waste water collection device 3. The condensing device 2 includes a condenser 4, The condenser 4 is provided with a condensation pipe 5, and the condensation pipe 5 is coiled in the condenser 4 in a spiral structure. The bottom end of the condenser 4 is provided with a water outlet 6, and the water outlet 6 is provided with a monitoring device 7, The outlet end of the supervisory device 7 is connected to the wastewater collection device 3 through a pipeline 8, the pipeline 8 is provided with a valve 9, and the supervisory device 7 is a hollow cup-shaped structure, including an upper supervisory device 12 and a lower supervisory device 13. The upper monitoring device 12 is a conical structure, the diameter d1 of its upper surface is larger than the diameter d2 of the lower surface, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com