A beater blade structure

A blade structure and beater technology, applied in mixers, mixer accessories, dissolving and other directions, can solve the problems of complex blade structure, high manufacturing cost, difficult to clean, etc., and achieve the effect of improving beating rate, simple structure, and preventing dead ends of beating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

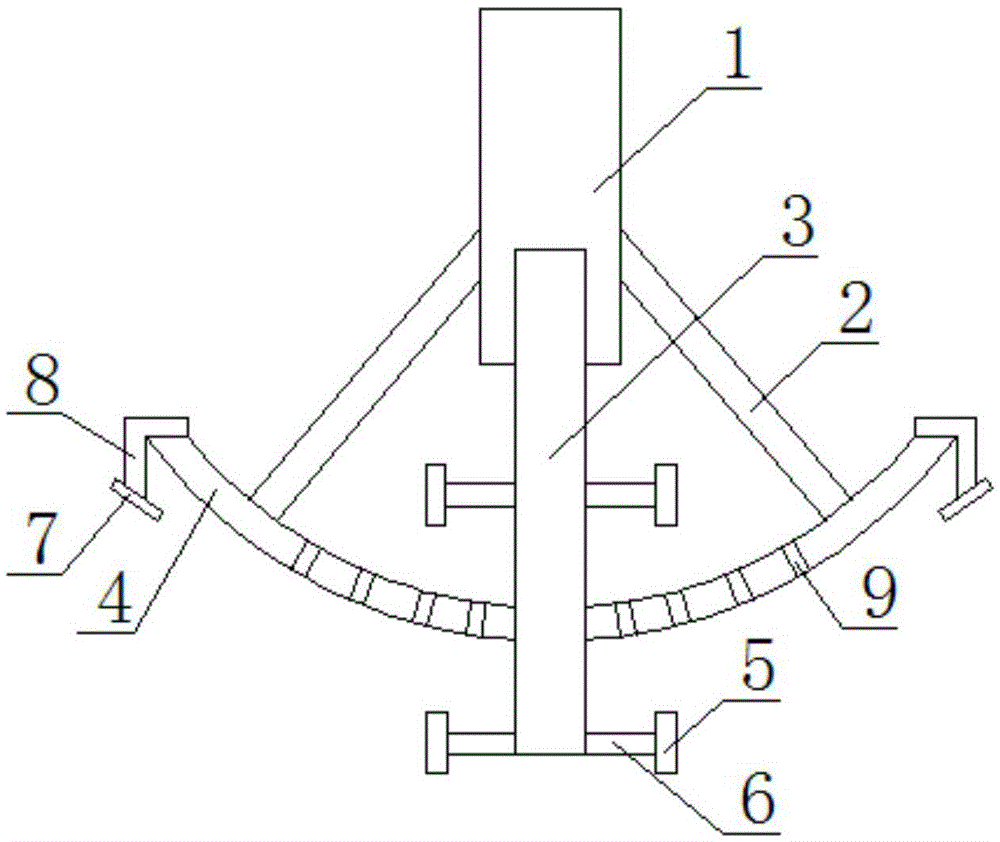

[0019] Such as figure 1 As shown, a beater blade structure includes an outer shaft 1, a connecting rod 2, an inner shaft 3, a main blade 4, a secondary blade 5, a connector 6, a guide plate 7 and a guide plate connecting seat 8;

[0020] One end of the outer shaft 1 is provided with an internal threaded hole along the central axis, one end of the inner shaft 3 is provided with an external thread, the inner shaft 3 is sleeved in the outer shaft 1, and the outer shaft 1 and the inner shaft 3 are connected by threads;

[0021] The main blade 4 is an arc-shaped sheet structure, the middle of the main blade 4 is provided with a through hole, the inner shaft 3 is sleeved in the through hole of the main blade 4, and the through hole diameter of the main blade 4 matches the rod diameter of the inner shaft 3 , The outer shaft 1 is connected with the inner arc surface of the main blade 4 through the connecting rod 2; the main blade 4 can also be provided with a number of filter holes 9 which ...

Embodiment 2

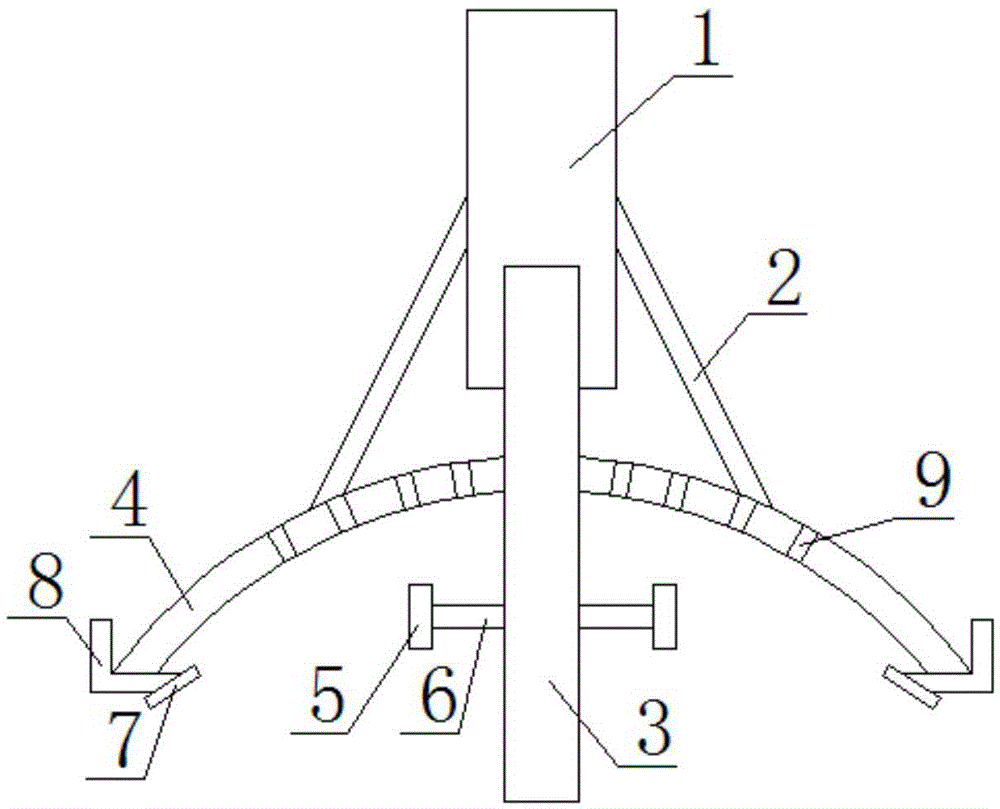

[0025] Such as figure 2 As shown, a beater blade structure includes an outer shaft 1, a connecting rod 2, an inner shaft 3, a main blade 4, a secondary blade 5, a connector 6, a guide plate 7 and a guide plate connecting seat 8;

[0026] One end of the outer shaft 1 is provided with an internal threaded hole along the central axis, one end of the inner shaft 3 is provided with an external thread, the inner shaft 3 is sleeved in the outer shaft 1, and the outer shaft 1 and the inner shaft 3 are connected by threads;

[0027] The main blade 4 is an arc-shaped sheet structure, the middle of the main blade 4 is provided with a through hole, the inner shaft 3 is sleeved in the through hole of the main blade 4, and the through hole diameter of the main blade 4 matches the rod diameter of the inner shaft 3 , The outer shaft 1 is connected with the outer arc surface of the main blade 4 through the connecting rod 2; the main blade 4 can also be provided with a number of filter holes 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com