A rotary barrel photocatalytic reaction device

A technology of photocatalytic reaction and rotating bucket, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes of energy application, etc. It can solve the problems of catalysts not being able to be renewed, dead angles of reaction devices, and utilization of light energy. Low-level problems, to achieve the effect of increasing light energy utilization and solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

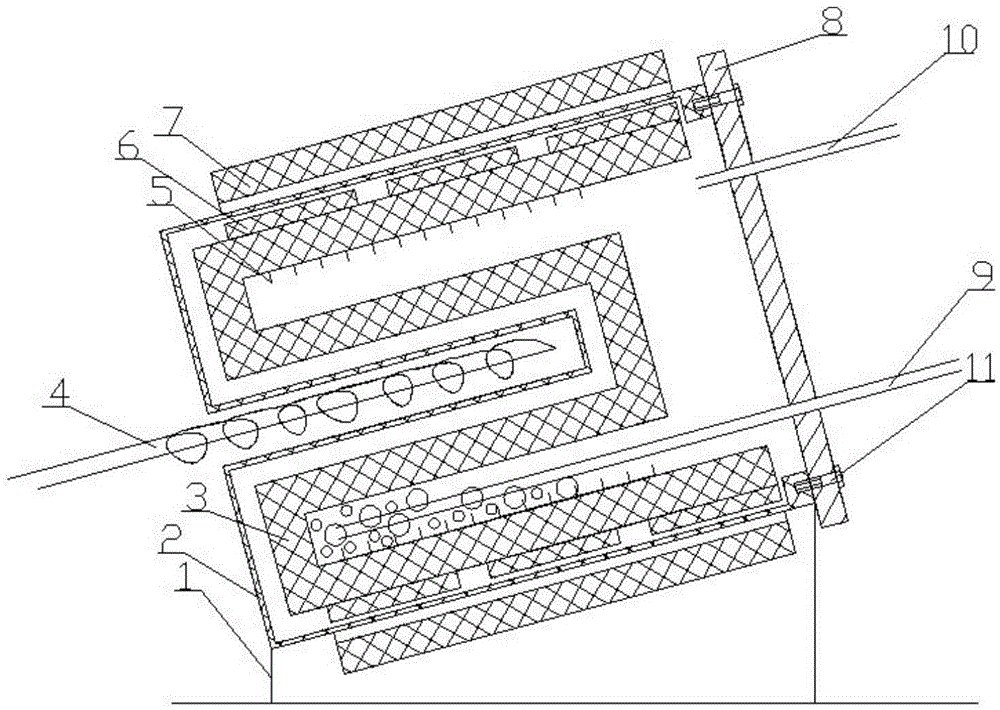

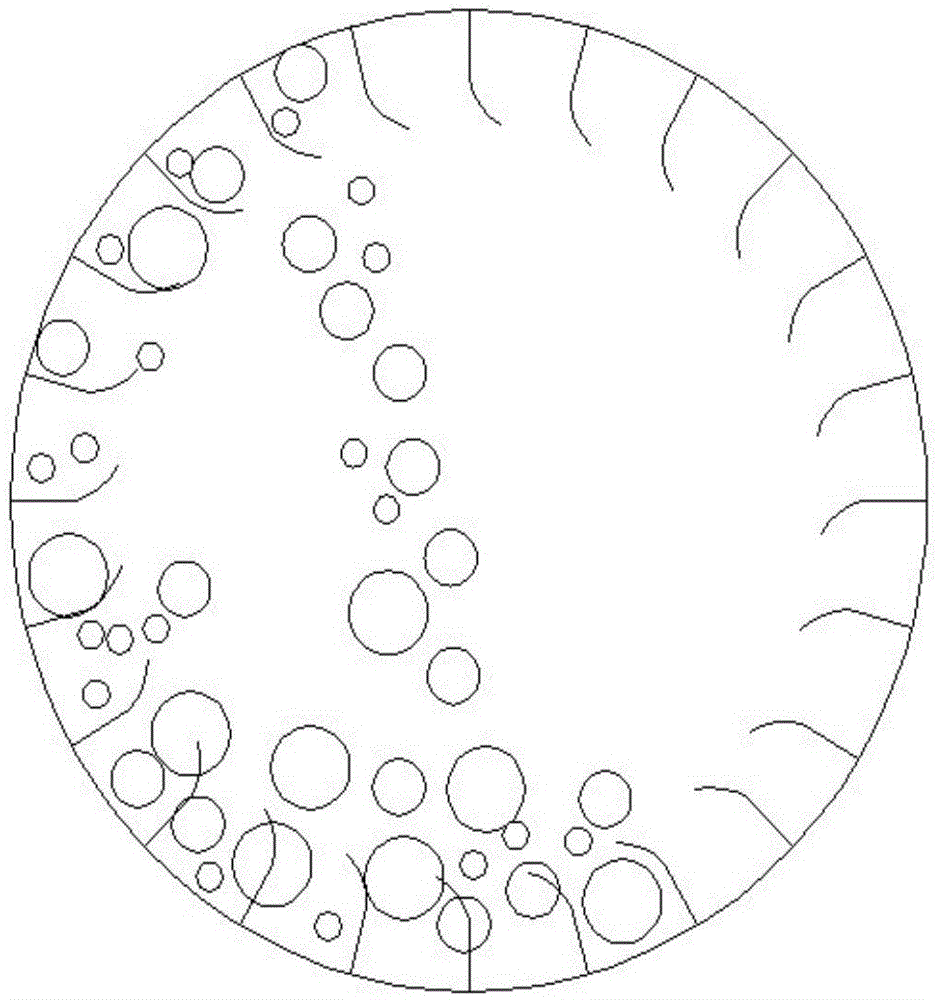

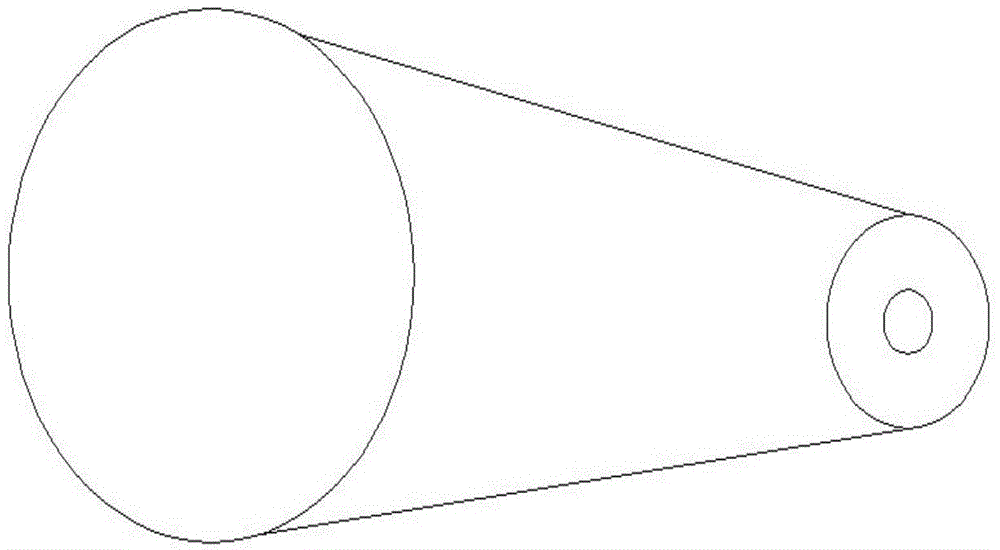

[0029] Such as Figure 1-4 As shown, the drum type photocatalytic reaction device provided by the present invention, the light contact area, according to Figure 4 It can be seen that the contact area between the catalyst and the light can be adjusted by adjusting the angle between the reactor and the ground. When the same amount of catalyst is loaded, the light area decreases as the inclination angle of the equipment increases.

[0030] The specific operation process is as follows,

[0031] 1) Open the sealing metal flange 8, load the catalyst, and tighten the screw 11.

[0032] 2) Turn on the motor, and the annular permanent magnet 7 drives the cylindrical inner cylinder 3 to rotate

[0033] 3) Open the gas inlet 9 to feed the reaction gas, and open the gas outlet 10 to keep the gas flowing.

[0034] 4) Turn on the light source 4, and the catalyst fully reacts with the reaction gas.

[0035] 5) After the reaction is finished, feed a certain amount of inert gas and all pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com