High-pressure powder protection ejector

An ejector and powder technology, which is applied to liquid ejection devices, gas ejection devices, gas ejection devices, etc., can solve the problems of limited power, weak launch power, unsustainable supply and enhancement, etc., and achieves flexible disassembly and easy use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

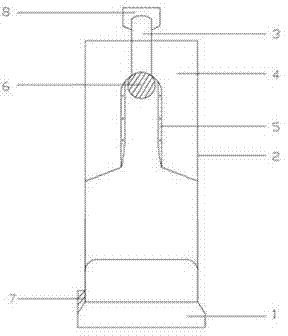

[0016] Example 1: Such as figure 1 As shown, a high-pressure powder protection injector includes a piston 1, a main body 2, an ejection port 3, a powder storage chamber 4, and a one-way valve 5, and is characterized in that: the inside of the main body 2 has a cavity; The piston 1 is connected to the cavity of the main body 2; the ejection port 3 is located at the front of the cavity of the main body 2; There is a one-way valve 5 in the space between the cavities.

Embodiment 2

[0017] Example 2: Such as figure 1 As shown, a high-pressure powder protection injector includes a piston 1, a main body 2, an ejection port 3, a powder storage chamber 4, a one-way valve 5, and an air pressure valve 6. It is characterized in that: the interior of the main body 2 is empty Cavity; the piston 1 is connected to the cavity of the main body 2; the ejection port 3 is located at the front of the cavity of the main body 2; the powder storage chamber 4 is located around the front end of the cavity of the main body 2 and contains irritating powder. There is a one-way valve 5 at a distance from the cavity of the main body 2; the air pressure valve 6 is installed in the cavity of the main body 2 and connected to the ejection port 3; the piston 1 is equipped with an electric drive device and a power supply, and the electric drive device is activated. The piston 1 can quickly move back and forth in a straight line, so that the gas in the umbrella handle main body 2 forms ...

Embodiment 3

[0018] Example 3: Such as figure 1 As shown, a high-pressure powder protection injector includes a piston 1, a main body 2, an ejection port 3, a powder storage chamber 4, a one-way valve 5, an air pressure valve 6, and a switch 7, and is characterized in that: the main body 2 There is a cavity inside; the piston 1 is connected to the cavity of the main body 2; the ejection port 3 is located at the front of the cavity of the main body 2; The powder is separated from the cavity of the main body 2 by a one-way valve 5; the air pressure valve 6 is installed in the cavity of the main body 2 and connected to the ejection port 3; the piston 1 is equipped with an electric drive device and a power supply to start the electric The driving device, the piston 1 can move back and forth quickly in a straight line, so that the gas in the umbrella handle main body 2 forms a high-pressure gas; a switch 7 is installed between the piston 1 and the main body 2, and the switch 7 can lock the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com