Material screening device

A material screening and screening technology, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. and other problems, to achieve the effect of large material screening use value, complete screening and novel principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

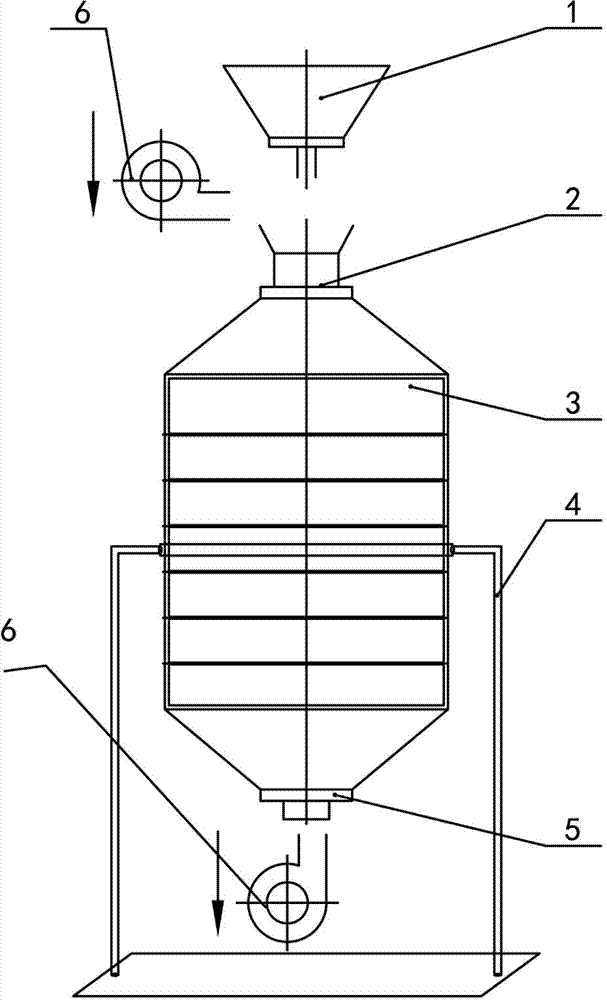

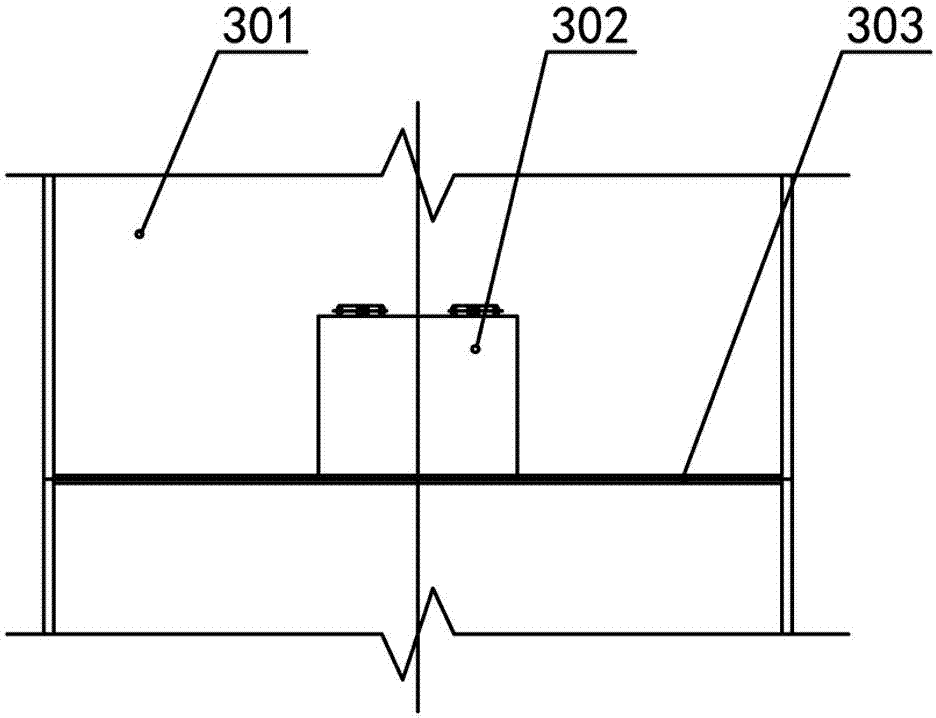

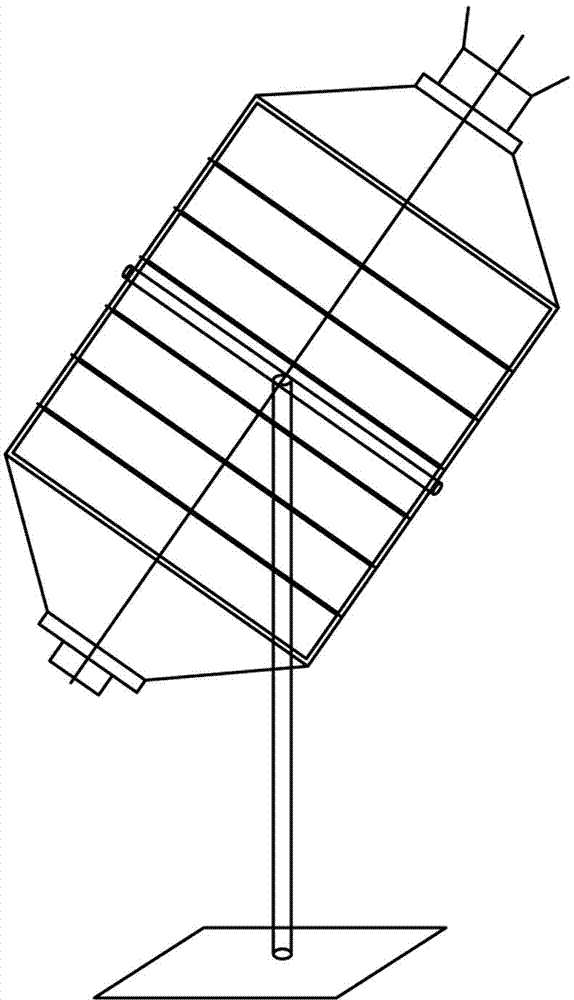

[0015] see Figure 1-4 , a material screening device, comprising a material storage device 1, a blowing device 2, a screening box body 3, a swing box body frame 4, a suction device 5, and a fan 6, and the screening box body includes a screening box outer wall 301 , the discharge opening switch door 302, the screen 303.

[0016] In the overall working mode of the screening device, the material first enters the storage device, and after weighing the quantitative material, it enters the screening working state. When screening, the blowing device and the suction device are turned on, resulting in negative pressure inside the screening box. According to the demand, the material is absorbed from the inlet of the blowing device, and the outlet of the storage device is opened, and the material enters the screening container. The blowing device and the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com