Magnetically sealed double-body vacuum cup

A thermos cup and magnetic sealing technology, applied in the field of thermos cups, can solve the problems of difficulty in manufacturing, obstructing the taking of cups, complicated switch structure, etc., and achieve the effects of maintaining integrity, reliable function and novel principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

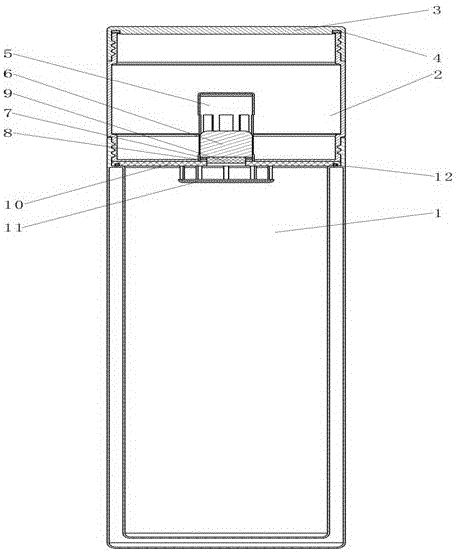

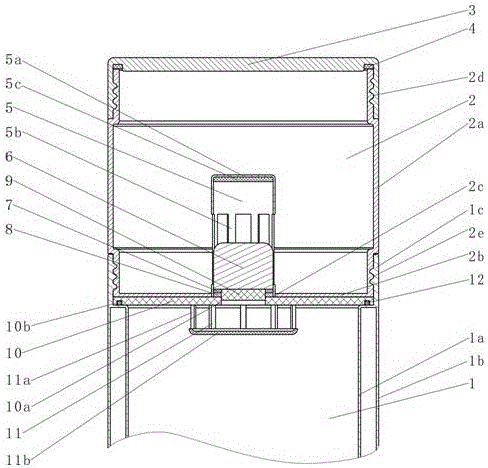

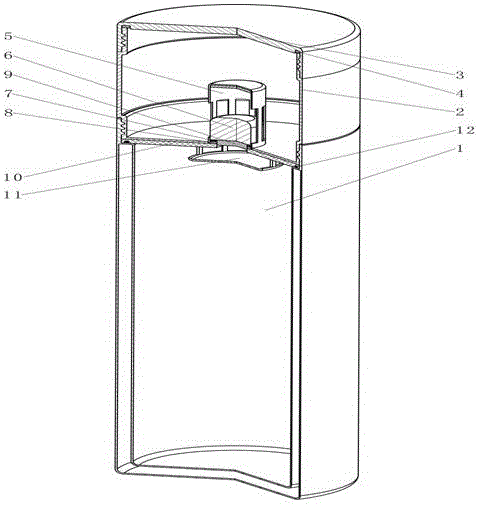

[0041] Example one, such as Figure 1 to Figure 5 As shown, the lower cup 1 is composed of an inner insulating layer 1a, an outer insulating layer 1b, and a lower cup mouth 1c. The lower cup mouth 1c is provided with internal threads.

[0042] The upper cup 2 is composed of an upper cup body 2a, an upper cup bottom 2b, a bottom hole 2c, and a heat insulation board 10. The cup opening of the upper cup body 2a and the lower end of the upper cup body 2a are respectively provided with a cup opening external thread 2d and a lower end external thread 2e, and the cup bottom hole 2c is located in the center of the upper cup bottom 2b. The lower external thread 2e of the upper cup body 2a and the internal thread of the lower cup opening 1c form a threaded connection. The heat insulation board 10 is placed at the bottom of the upper cup body 2a, and its center has a heat insulation board through hole 10a smaller than the bottom hole 2c of the cup. The outer end of the heat insulation boar...

Embodiment 2

[0047] Example two, such as Figure 6 to Figure 9 As shown, different guides 5 are used. The guide device 5 can be composed of a guide ring 5e and a guide ring connecting strip 5d. The guide ring 5e is a circular ring member, and the outer edge of the guide ring 5e is distributed with notches corresponding to the anti-rush cover connecting strip 11a, so that the guide ring 5e can slide along the anti-rush cover connecting strip 11a. There are 10 guide ring connecting strips 5d, one end is distributed and connected to the inner edge of the guide ring 5e. The guide ring 5e is connected to the heat insulation layer 9 through the guide ring connecting strip 5d. The guide ring 5e also limits the drop of the weight 6.

Embodiment 3

[0048] Example three, such as Figure 10 to Figure 12 As shown, there is another guiding device 5. The guide device 5 is composed of a guide ring 5h, a connecting rib 5i, a guide hole 11c, a guide rod 5f, and a limit cap 5g. The guide ring 5h is an annular piece, which is connected to the inner side of the through hole 10a of the heat insulation board through four connecting ribs 5i. The guide hole 11c is a through hole opened in the center of the anti-rush cover 11, the limit cap 5g is connected to the lower end of the guide rod 5f in a disc shape, and the upper end of the limit rod 5f passes through the guide hole 11c and the guide ring 5h to connect with the heat insulation layer 9. . The limit cap 5g has a limit effect on the drop of the heavy hammer 6.

[0049] The working process of the embodiment is:

[0050] Unscrew the upper cup 2, inject hot water into the lower cup 1, and then tighten the upper cup 2. Due to the heat insulation effect of the heat insulation board 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com