Mould opening/closing system of injection mould device

An injection mold and mold technology, which is applied in the field of injection mold device clamping and mold opening system, can solve the problems of long injection preparation time, long processing time, high mold cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

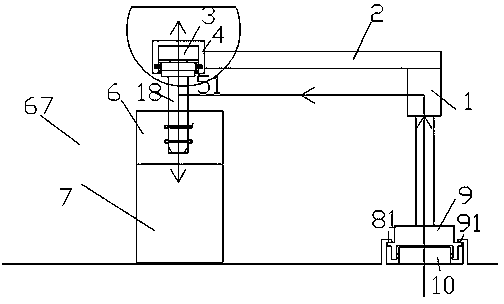

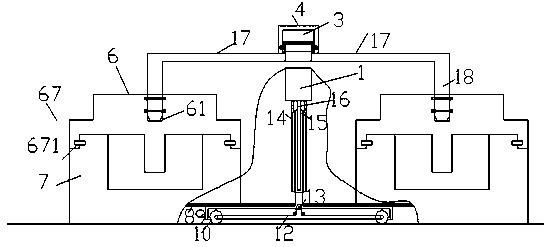

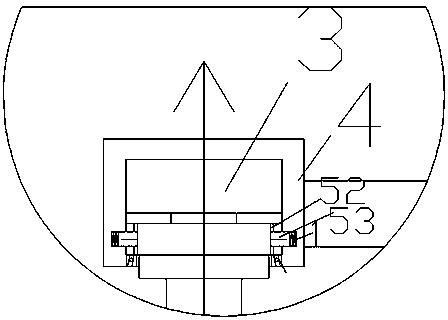

[0014] Combine below Figure 1-4 The present invention will be described in detail.

[0015] A mold clamping and opening system for an injection mold device, comprising a mold clamping and opening device, a sliding track, and at least two injection mold device groups 100, 200, at least two injection mold device groups are distributed along the extending direction of the sliding track, and each Each includes four injection mold devices 67, and the four injection mold devices 67 are arranged in a square layout, and each injection mold device 67 occupies a vertex of the square layout; the mold clamping and mold opening device includes a lifting support frame body, The liftable support frame body includes a lifting motor 1, the rotating shaft of the lifting motor 1 is connected with the lifting screw rod 16, the lifting screw rod 16 is screwed with the internal thread sleeve 15, and the outer peripheral surface of the internal thread sleeve 15 is provided with a longitudinally ext...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap