Bottle

A bottle and bottleneck technology, applied in the field of bottles with anti-theft and anti-leakage functions, can solve problems such as the anti-theft point is difficult to break, the bottle cap is difficult to open, and the liquid expires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

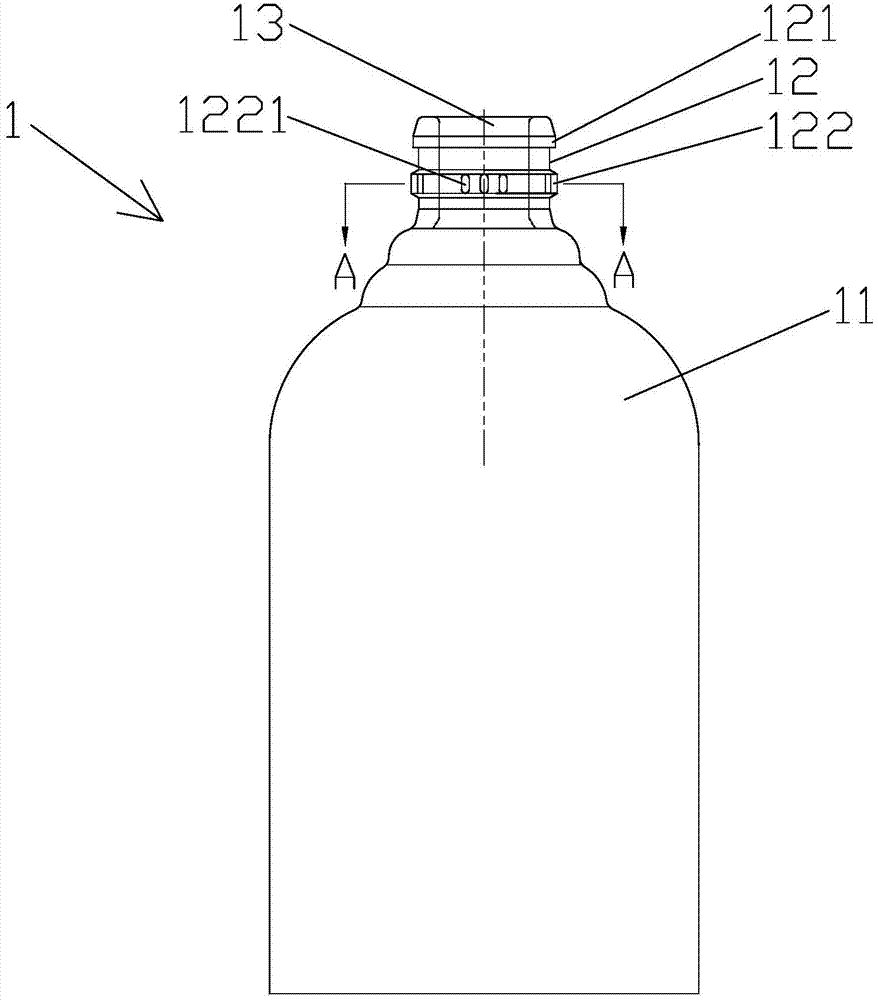

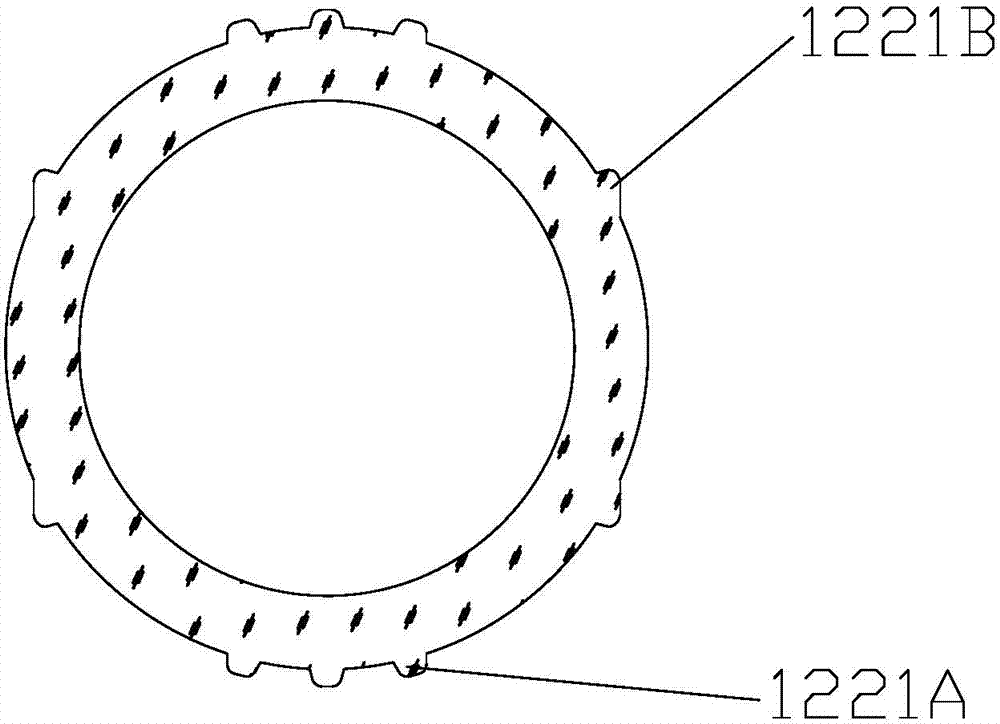

[0027] Embodiment, a kind of bottle, such as figure 1 As shown, the bottle 1 includes a bottle body 11, a bottleneck 12 and a bottleneck 13. On the peripheral wall of the bottleneck 12, an upper convex ring 121 and a lower convex ring 122 are arranged, and a plurality of convex rings 122 are arranged on the lower convex ring 122. teeth 1221, specifically, as figure 2 As shown, the convex teeth 1221 include 6 arc-shaped convex teeth 1221A and 4 inclined convex teeth 1221B; the arc-shaped convex teeth 1221A are divided into two groups and each group includes 3 arc-shaped convex teeth, and the inclined convex teeth 1221B Divided into two groups and each group includes 2 inclined convex teeth, a set of inclined convex teeth is provided between each two groups of arc-shaped convex teeth, and the inclination direction of the two adjacent inclined convex teeth in each group On the contrary, the bottle cap 2 is fitted on the bottle mouth 13 .

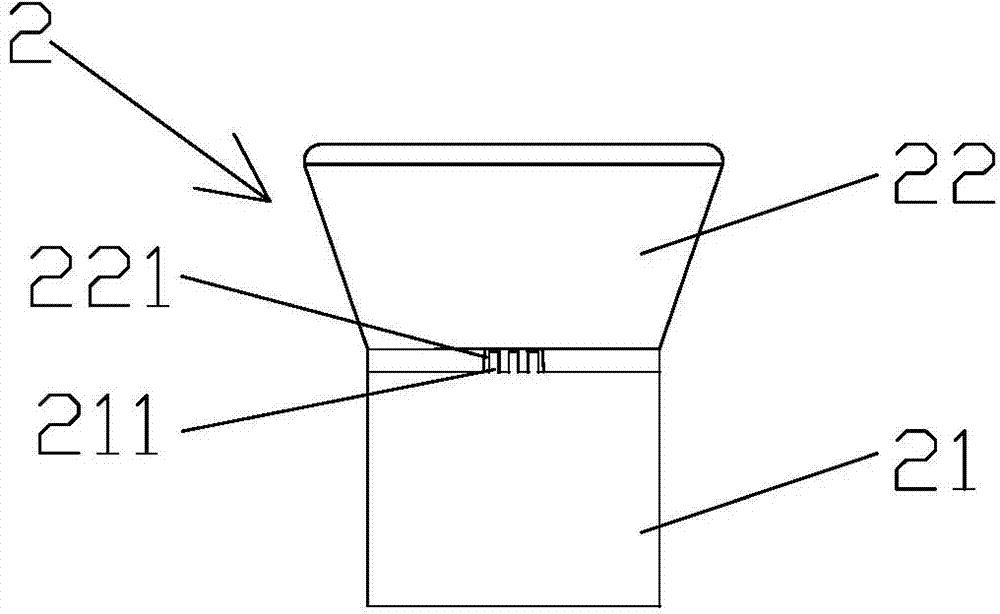

[0028] Such as image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com