Environment-friendly high-temperature-resistant gas oil synthetic-based drilling fluid and preparation method and application thereof

A gas-to-oil, high-temperature-resistant technology, applied in the field of environmentally friendly high-temperature-resistant gas-to-oil synthetic base drilling fluid, can solve the problems of oil-based drilling fluid pollution, application and promotion restrictions, etc., and achieve good rheology and good high-temperature emulsification The effect of agent stability and good high temperature and high pressure filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

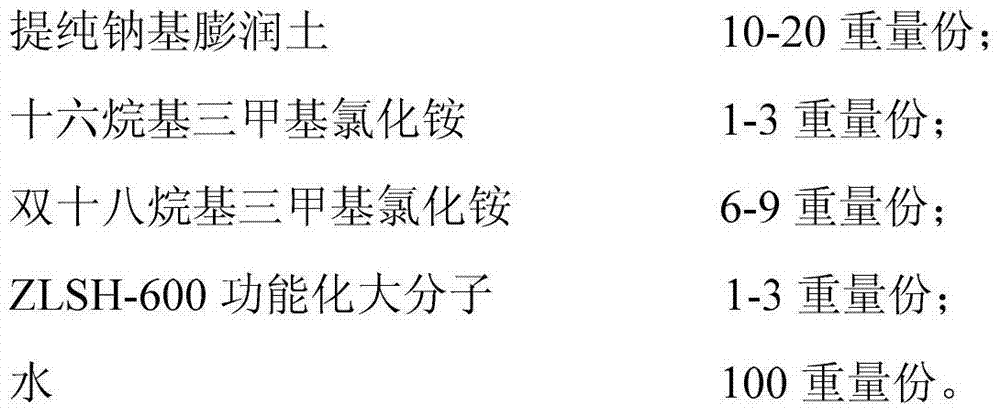

[0041] This embodiment provides an environmentally-friendly high-temperature resistant gas-to-liquid synthetic base drilling fluid, which, in parts by weight, includes the following components:

[0042] 80 parts by weight of gas to oil, 20wt% of CaCl 2 20 parts by weight of aqueous solution, main emulsifier DREM-13 by weight, auxiliary emulsifier DRCO-13 by weight, organic soil DRGEL 2 parts by weight, fluid loss agent DF014 by weight, calcium oxide 2 parts by weight, and barite 215 parts by weight .

[0043] The environment-friendly high-temperature resistant gas-to-liquid synthetic base drilling fluid of this embodiment is prepared by the following method:

[0044] Add the main emulsifier DREM-1 and the auxiliary emulsifier DRCO-1 to the gas oil, and stir at high speed for 20 minutes to obtain the first mixed liquid;

[0045] Add 20wt% CaCl to the first mixed solution 2 The aqueous solution was stirred at high speed for 30 minutes to obtain the second mixed solution;

[0046] Add the...

Embodiment 2

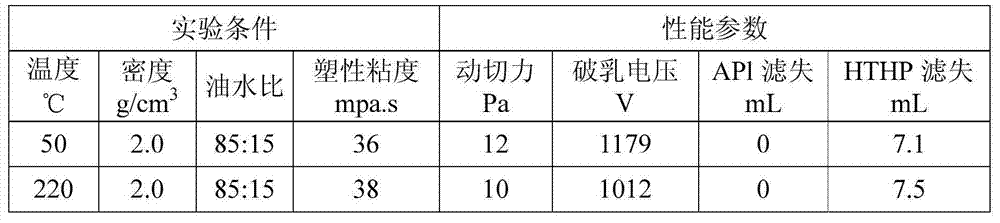

[0054] This embodiment provides an environmentally-friendly high-temperature resistant gas-to-liquid synthetic base drilling fluid, which, in parts by weight, includes the following components:

[0055] 85 parts by weight of gas to oil, concentration of 20wt% CaCl 2 15 parts by weight of aqueous solution, main emulsifier DREM-13 by weight, auxiliary emulsifier DRCO-13 by weight, organic clay DRGEL 2 parts by weight, fluid loss reducer DF014 by weight, calcium oxide 2 parts by weight, and barite 215 parts by weight.

[0056] The environment-friendly high-temperature resistant gas-to-liquid synthetic base drilling fluid of this embodiment is prepared by the following method:

[0057] Add the main emulsifier DREM-1 and the auxiliary emulsifier DRCO-1 to the gas oil, and stir at high speed for 20 minutes to obtain the first mixed liquid;

[0058] Add 20wt% CaCl to the first mixed solution 2 The aqueous solution was stirred at high speed for 30 minutes to obtain the second mixed solution;

...

Embodiment 3

[0067] This embodiment provides an environmentally-friendly high-temperature resistant gas-to-liquid synthetic base drilling fluid, which, in parts by weight, includes the following components:

[0068] 90 parts by weight of gas to oil, 20wt% of CaCl 2 10 parts by weight of aqueous solution, main emulsifier DREM-13 by weight, auxiliary emulsifier DRCO-15 by weight, organic clay DRGEL 3 by weight, fluid loss reducer DF015 by weight, calcium oxide 2 by weight, and barite 318 by weight.

[0069] The environment-friendly high-temperature resistant gas-to-liquid synthetic base drilling fluid of this embodiment is prepared by the following method:

[0070] Add the main emulsifier DREM-1 and the auxiliary emulsifier DRCO-1 to the gas oil, and stir at high speed for 20 minutes to obtain the first mixed liquid;

[0071] Add 20wt% CaCl to the first mixed solution 2 The aqueous solution was stirred at high speed for 30 minutes to obtain the second mixed solution;

[0072] Add the organic soil DRGE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Dynamic shear force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com