An ionic rare earth concentrate acid leaching process

An ionic rare earth and acid leaching technology, applied in the field of chemical metallurgy, can solve the problem of not considering the recovery of radioactive elements, high recovery cost, high maintenance cost, improve the total yield of rare earth and impurity removal effect, and reduce the consumption of acid , the effect of reducing the difficulty of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

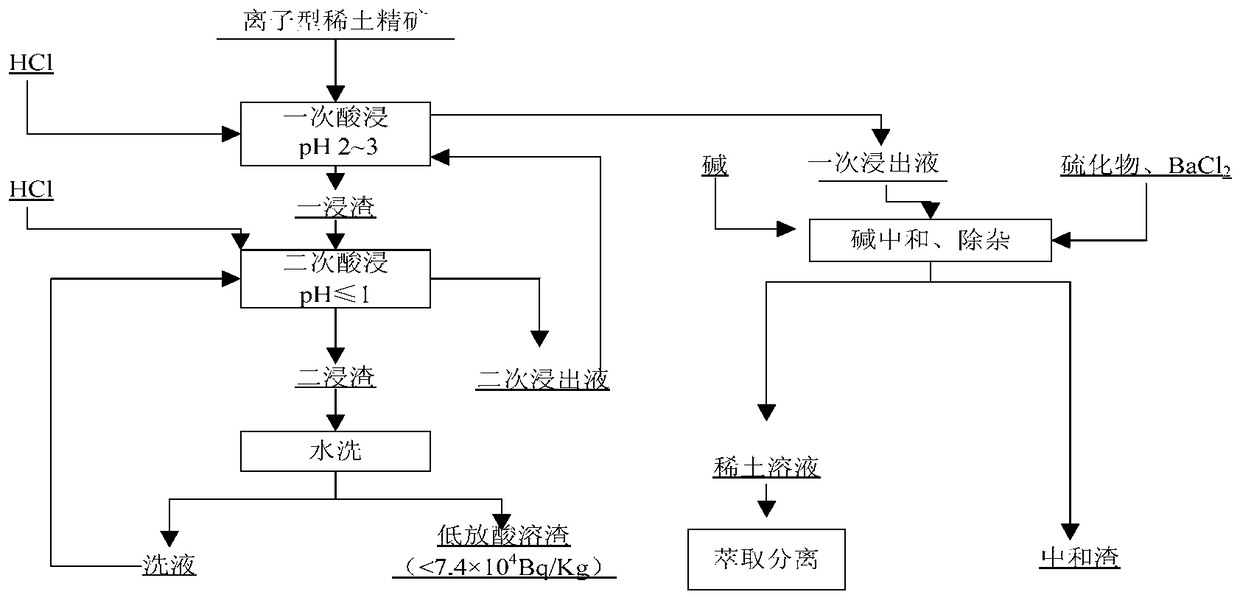

[0062] The rare earth concentrate is an oxide containing a small amount of radioactive substances, which belongs to the medium-yttrium-europium-rich ion type rare earth ore, containing 92% REO (that is, calculated as rare earth oxide), and is leached by the acid leaching process of the ion type rare earth concentrate of the present invention. The specific steps as follows:

[0063] Use the secondary leaching solution and neutralized slag washing water as the bottom water, gradually add 8mol / L hydrochloric acid and 1 ton of concentrate to the bottom water, control the pH value of the reaction system to 3, control the reaction temperature to 50°C, and stir and leach for 6 hours. A plate and frame filter press was used for solid-liquid separation to obtain a primary slag and a primary leachate, and the rare earth content in the primary leachate was 270 g / L as REO.

[0064] The primary slag is subjected to secondary acid leaching with hydrochloric acid with a concentration of 8.0m...

Embodiment 2

[0068] The rare earth concentrate is an oxide containing a small amount of radioactive substances, which belongs to the medium-yttrium-europium-rich ion type rare earth ore, containing 92% REO (that is, calculated as rare earth oxide), and is leached by the acid leaching process of the ion type rare earth concentrate of the present invention. The specific steps as follows:

[0069] Use the secondary leaching solution and neutralized slag washing water as the bottom water, gradually add 8mol / L hydrochloric acid and 1 ton of concentrate to the bottom water, control the pH value of the reaction system to 3, control the reaction temperature to 50°C, and stir and leach for 6 hours. A plate and frame filter press was used for solid-liquid separation to obtain a primary slag and a primary leachate, and the rare earth content in the primary leachate was 270 g / L as REO.

[0070] The primary slag is subjected to secondary acid leaching with hydrochloric acid with a concentration of 8.0m...

Embodiment 3

[0074] The rare earth concentrate is an oxide containing a small amount of radioactive substances, which belongs to the medium-yttrium-europium-rich ion-type rare-earth ore, and contains 90% REO. It is leached by the acid leaching process of the ion-type rare earth concentrate of the present invention. The specific steps are as follows:

[0075] Use the secondary leaching solution and neutralized slag washing water as the bottom water, gradually add hydrochloric acid with a concentration of 9.5mol / L and 1 ton of concentrate into the bottom water to control the reaction temperature at 85°C, the reaction time is 4 hours, and the final pH value is controlled at 2.5. The frame filter press performs solid-liquid separation to obtain primary slag and primary leachate, and the rare earth content in the primary leachate is 250g / L in terms of REO.

[0076] The primary slag is subjected to secondary acid leaching with hydrochloric acid with a concentration of 9.5mol / L, the acidity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radioactive decay specific activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com