An energy-saving window with a broken bridge aluminum alloy hidden fan

An aluminum alloy, energy-saving window technology, applied in the layout of windows/doors, wing sashes, window/door frames, etc., can solve problems such as weak strength and wind resistance, window deformation, reduced thermal insulation, sound insulation, etc. The effect of improving wind resistance and deformation resistance, improving thermal insulation and sound insulation performance, and enhancing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

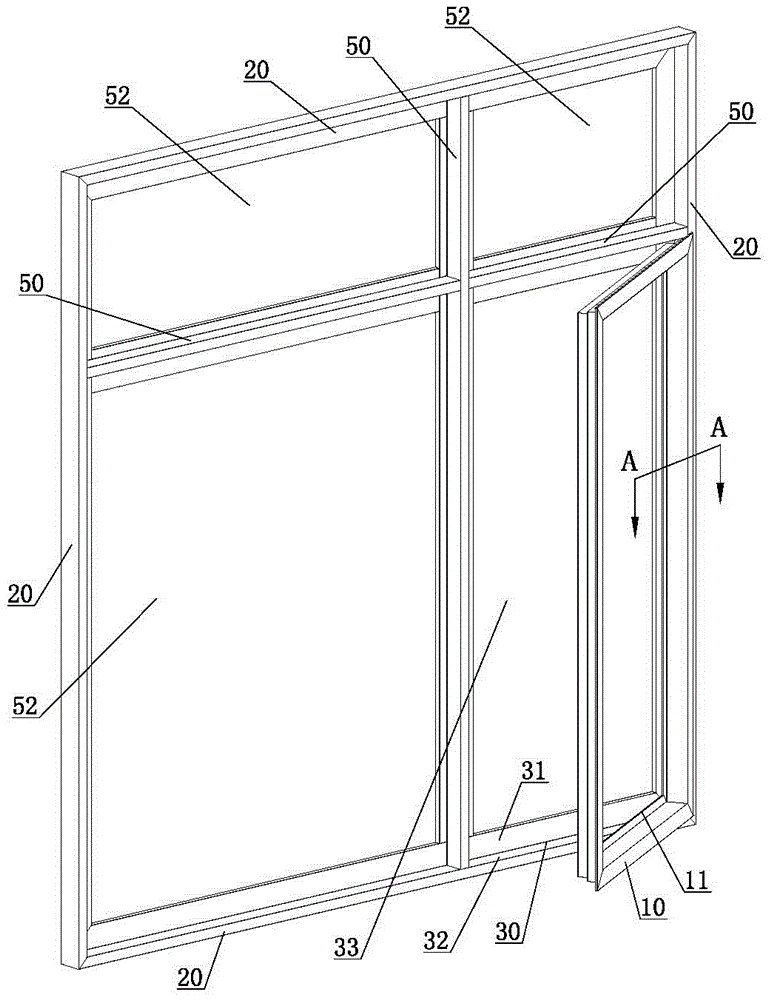

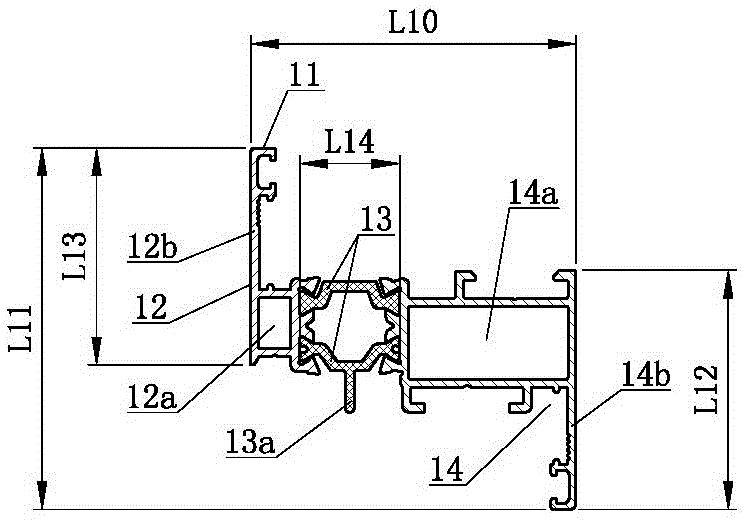

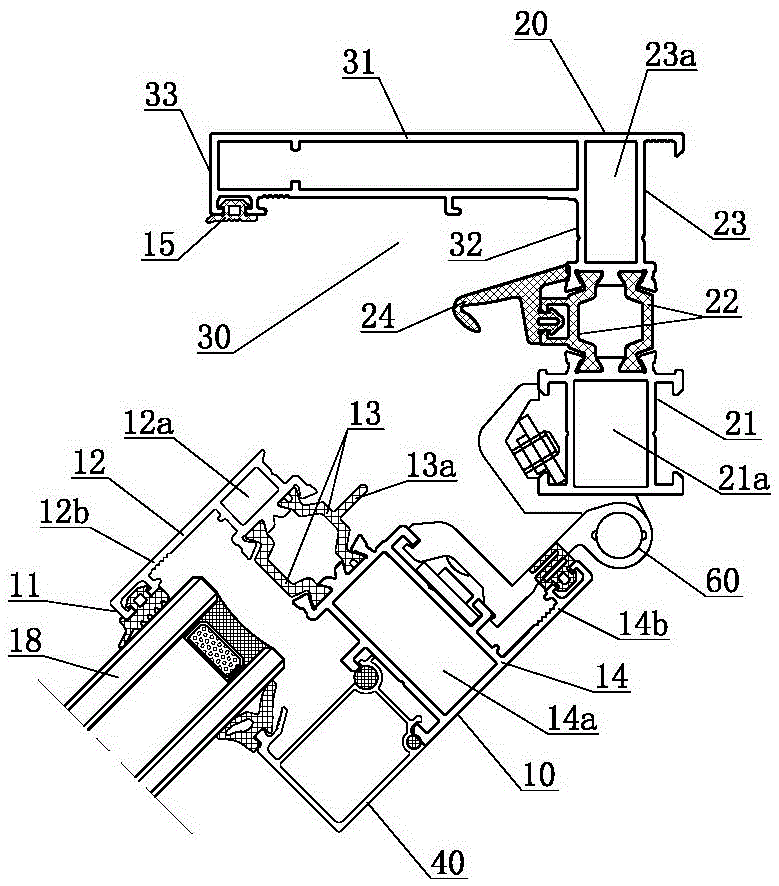

[0045] The utility model relates to a window sash profile, which is used to make a window sash of an energy-saving window with a hidden aluminum alloy fan on a broken bridge.

[0046] Such as figure 2 , the window sash profile is a profile formed by compounding a broken bridge aluminum profile and a heat-insulated broken bridge; The thickness of the sash profile (including the total thickness of the three parts of the sash outdoor profile, sash insulation bridge, and sash interior profile) is L10=58.5mm, and the width of the sash profile (including the sash exterior profile, sash insulation bridge, and sash interior profile three parts) is L10=58.5mm. Part total width) L11=65mm.

[0047] The indoor profile of the sash is an aluminum alloy profile, and the indoor profile of the sash is provided with a cavity 14a and a wing 14b. The cavity size of the cavity of the indoor profile of the sash is 28.7mm×13.2mm, and the dimension of the wing is L12=43mm.

[0048] The outdoor pro...

Embodiment 2

[0057] The utility model relates to a frame section material, which is used for making a window frame body of an energy-saving window of an aluminum alloy concealed fan with a broken bridge.

[0058] Such as Image 6 , the frame profile is a profile composed of a broken bridge aluminum profile and a heat-insulated broken bridge. The frame profiles include frame indoor profiles 21 , frame thermal break bridges 22 , and frame outdoor profiles 23 . The thickness of the frame profile (including the total thickness of the three parts of the frame outdoor profile, the frame insulation bridge, and the frame indoor profile) is L20=65mm, and the width of the frame profile is L21=85mm.

[0059] The frame indoor profile is an aluminum alloy profile, and the frame indoor profile is provided with a cavity 21a, and wing edges 21b are arranged on both sides of the cavity of the frame indoor profile; the cavity size of the frame indoor profile cavity is 19.2mm ×13.2mm, wing size L22=26mm. ...

Embodiment 3

[0068] The utility model relates to a stile profile, which is used for making a window frame body of an energy-saving window of an aluminum alloy hidden fan with a broken bridge.

[0069] Such as Figure 10 , the stile profile is a composite profile of a broken bridge aluminum profile and a heat-insulated broken bridge; The thickness of the mullion profile (including the total thickness of the three parts of the mullion outdoor profile, the mullion thermal break bridge, and the mullion indoor profile) is L50=64.7mm, and the width of the mullion profile is L51=109mm.

[0070] The stile indoor profile is an aluminum alloy profile, and the stile indoor profile is provided with a cavity 53a, and wings 53b are provided on both sides of the cavity of the stile indoor profile; the cavity size of the stile indoor profile cavity is 19.2 mm×13.2mm, wing edge size L52=26mm.

[0071] The outdoor profile of the stile is an aluminum alloy profile, and the outdoor profile of the stile is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com