Device used for pump cavitation experiment and implementation method thereof

An implementation method and experimental technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as poor equipment versatility and cumbersome operation, and achieve the effects of improving efficiency, simplifying test methods, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

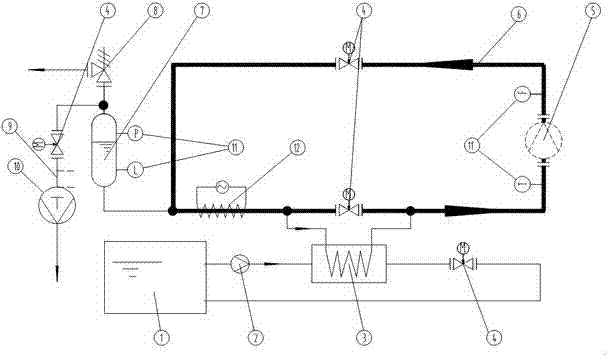

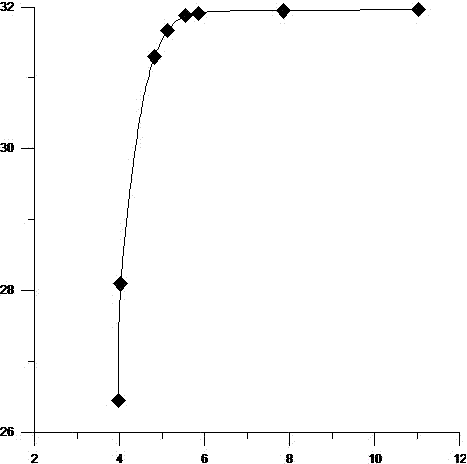

[0029] Such as figure 1 The device used for pump cavitation experiment is shown as an example. The rated flow rate of the pump is 93t / h and the head is 32mH. 2 O, first connect the test pump 5 to the test circuit, after the connection is completed, fill the system with water, and establish the initial pressure of the surge tank 7, start the test pump 5, and adjust the test flow by adjusting the regulating valve 4 on the test outlet pipeline After reaching 93t / h, after the operation is stable, start the water ring vacuum device 10, and slightly open the regulating valve 4 between the surge tank 7 and the water ring vacuum device, and stop the water ring vacuum after the pressure in front of the test pump reaches the required vacuum degree Device 10, carries out data collection by relevant measuring instrument 11, collects data such as figure 2 As shown by the diamond-shaped solid points in , figure 2 The middle abscissa is NPSH, unit / mH 2 O; the ordinate is the pump head, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com