Hub bearing unit equipped with a low friction sealing assembly

一种轮毂轴承、密封组件的技术,应用在轴承元件、旋转运动的轴承、轮毂等方向,能够解决组装工作难、复杂形状增加成本、增加体积等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

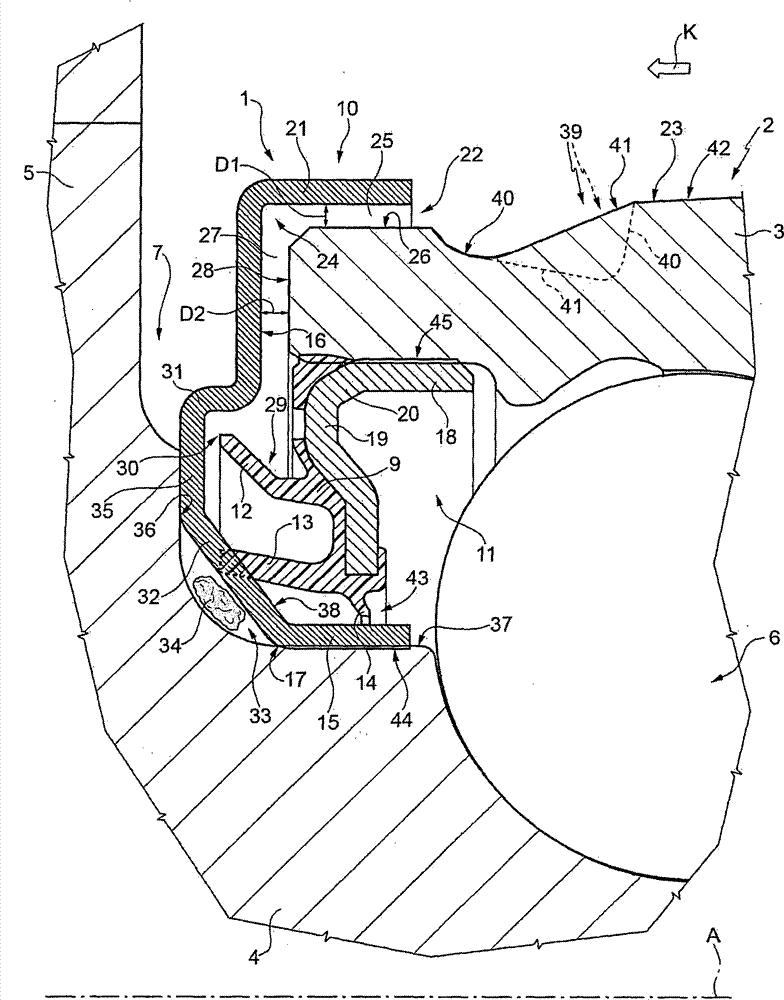

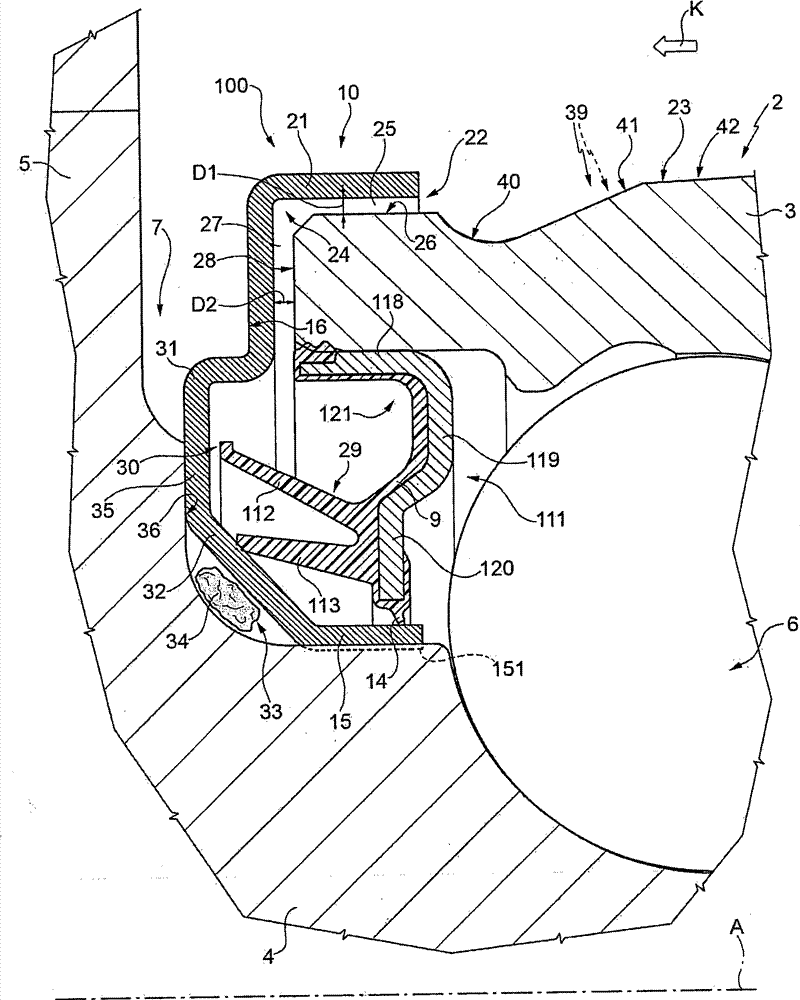

[0013] figure 1 The number 1 in refers to a low-friction sealing assembly, especially designed to be mounted on a hub bearing unit 2 of a vehicle, in which the sealing assembly 1 is integrated in use.

[0014] A hub bearing unit 2 of known type comprises an outer ring 3 fixed in use, an inner ring 4 rotating in use about an axis A, and at least the tops of rolling bodies 6 inserted between the outer ring 3 and inner ring 4, axis A Also the axis of symmetry of the rings 3 and 4, which are coaxial with each other, the ring 4 has a flanged end 5 opposite to the outer ring 3 and serves to carry the wheel.

[0015] The seal assembly 1 is inserted into the annular gap 7 defined between the fixed outer ring 3 and the rotating inner ring 4 of the hub bearing 2, and more particularly, between the coaxial rotating part 4 and the fixed part 3 of a universal rolling bearing of known type Between them, they are a part of the hub bearing 2 or integrated with it.

[0016] The seal assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com