Water energy circulation stove water heater

A technology for water heaters and earth stoves, which is applied to stoves/stoves with hot water devices, household heating, heating methods, etc., can solve the problems of poor circulation loop fluidity and inability to adjust the outlet water temperature, and achieve the effect of promoting circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

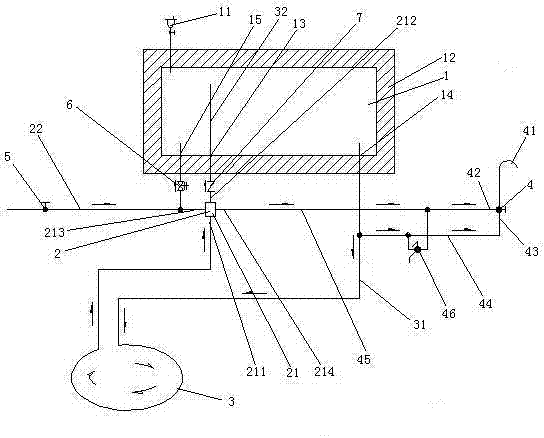

[0035] Embodiment one, see figure 1 What is claimed is an earthen stove water heater with water energy circulation, comprising a water tank 1, a circulation promoter 2, a heat exchange coil 3 and a shower faucet 4.

[0036] The top wall of the water tank 1 is provided with an exhaust valve 11 . The outside of the water tank 1 is wrapped with an insulating layer 12 . The bottom wall of the water tank 1 is provided with a circulating water inlet 13 , a circulating water outlet 14 and a pressure relief port 15 .

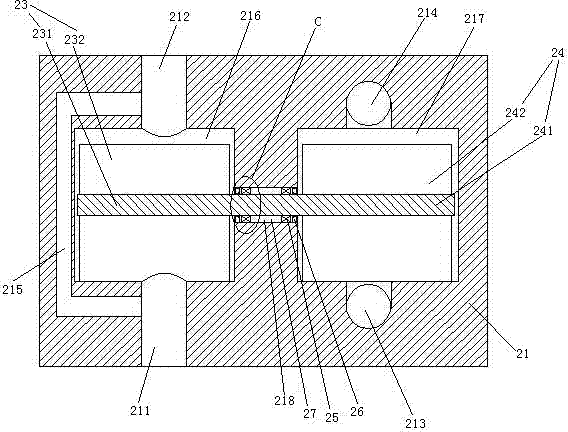

[0037] The circulation booster 2 includes a housing 21 . The casing 21 is provided with a first water inlet 211 , a first water outlet 212 , a second water inlet 213 and a second water outlet 214 . The second water inlet 213 is connected with the cold water inlet pipe 22 . The cold water inlet pipe 22 is provided with a stop valve 5 . A check safety valve 6 is provided between the cold water inlet pipe 22 and the pressure relief port 15 . The outlet end of check s...

Embodiment 2

[0044] Embodiment two, the difference with embodiment one is:

[0045] see Figure 4 , The bottom of the water tank 1 is provided with a rubber pad 8. There are four rubber pads 8.

[0046] see Figure 5 , The bottom surface of the rubber pad 8 is provided with a liquid storage cavity 81 . An isolation plate 82 is provided in the liquid storage chamber 81 . The isolation plate 82 divides the liquid storage chamber 81 into an upper liquid storage chamber 811 and a lower liquid storage chamber 812 . The lower end of the lower liquid storage chamber 812 is provided with a rubber cover 83 . The rubber cover 83 is in the shape of a bowl arched towards the inside of the lower liquid storage chamber 812 . A skeleton 84 is arranged inside the rubber pad 8 . The frame 84 is a coil spring that expands and contracts in the vertical direction. The liquid storage cavity 81 is located inside the space surrounded by the skeleton 84 . The isolation plate 82 is provided with several m...

Embodiment 3

[0050] Embodiment three, the difference with embodiment two is:

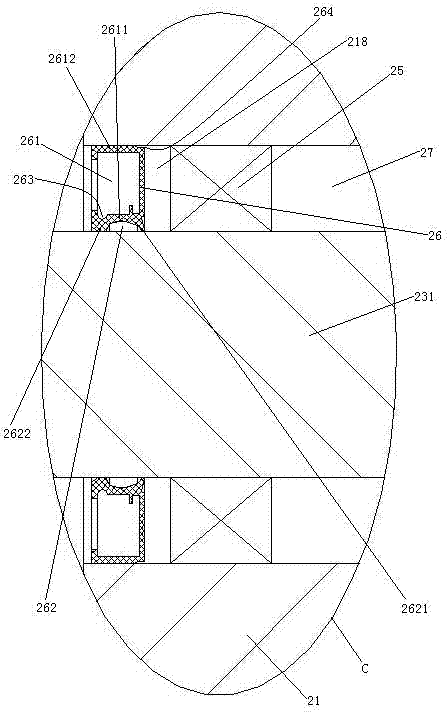

[0051] see Figure 8 , also includes oil replenishment mechanism 9. The shaft hole 218 is also provided with an oil filling hole 219 . The outlet end of the oil filling hole 219 is located in the sealed cavity 27 . The oil replenishing mechanism 9 includes an oil storage tank 91 , an oil outlet channel 92 and a corrosive liquid storage tank 94 .

[0052] One end of the oil outlet passage 92 is provided with a filler nozzle 922 , and the other end is provided with an oil inlet bucket 921 . The filler nozzle 922 is butted together with the filler hole 219 . The oil inlet hopper 921 is located below the oil storage tank 91 . The filler nozzle 922 is lower than the oil storage tank 91 , that is, the oil in the oil outlet channel 92 can automatically flow into the filler nozzle 922 and enter the sealed cavity 27 .

[0053] The corrosive liquid storage tank 94 is connected with the variable casing 21 together. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com