Rotary kiln air cooling device

An air-cooling device and rotary kiln technology, applied in the field of cement kiln production equipment, can solve the problems of easy oxidation and damage of metal parts, increase labor intensity of maintenance personnel, increase use and maintenance costs, etc., achieve simple structure, reduce use and The effect of improving maintenance cost and operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

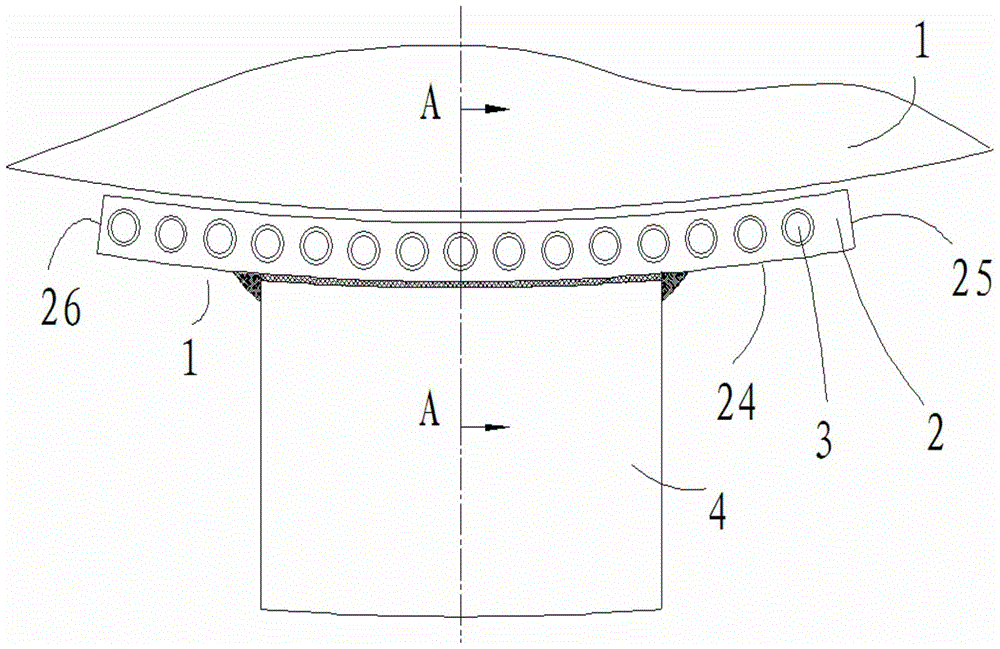

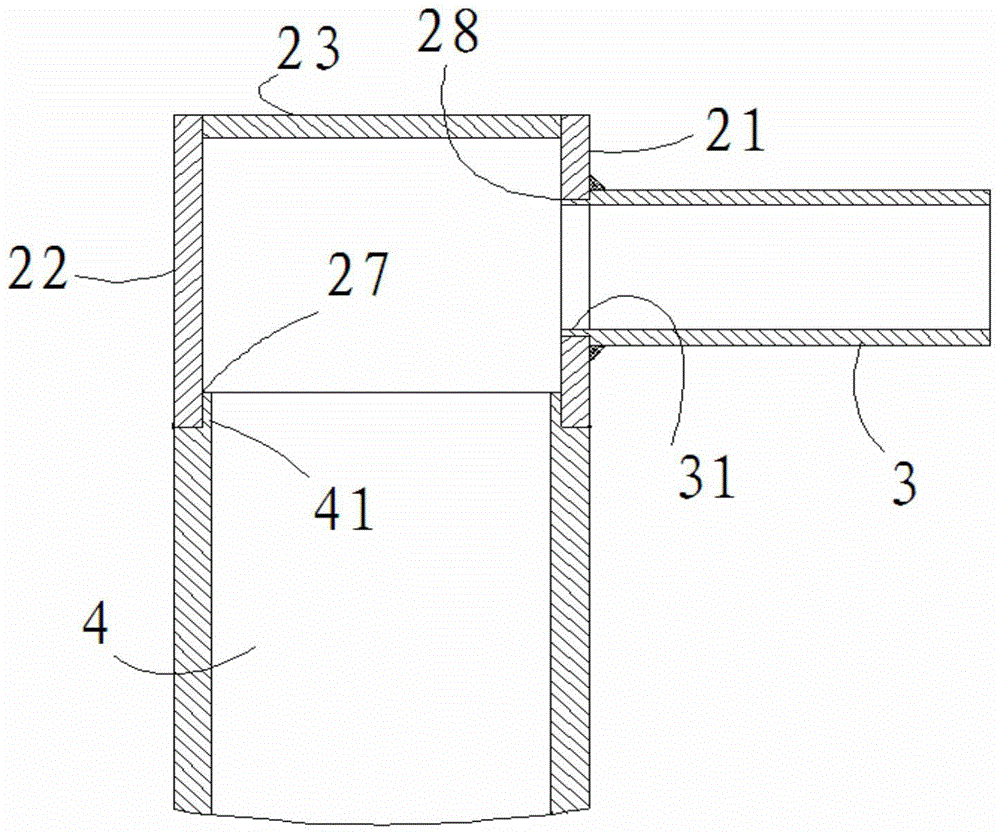

[0015] Such as figure 1 , figure 2 As shown, a rotary kiln air-cooling device includes a cold air sleeve and a kiln shell 1. The cold air sleeve is provided with a cold air port, and a cold air pipe 2 is provided near the outer cylindrical surface of the kiln shell 1. The cold air pipe 2 includes inner arc plate 23, outer arc plate 24, left sealing plate 26, right sealing plate 25, front sealing plate 21, rear sealing plate 22, said inner arc plate 23, outer arc plate 24, left sealing plate Plate 26, right sealing plate 25, front sealing plate 21, and rear sealing plate 22 are welded to form a sealed space. The inner cylindrical surface of the inner circular arc plate 23 cooperates with the outer cylindrical surface of the kiln shell 1, and the front sealing plate 21 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com