A gate valve leak detection chuck controlled by a single hydraulic cylinder for pressing multiple jaws

A sealing detection, single hydraulic cylinder technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the overall bulky gate valve air tightness detection device and the movement of the pressing block Problems such as poor coordination and inflexible activities can achieve the effects of reducing equipment quality, improving compaction accuracy, and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

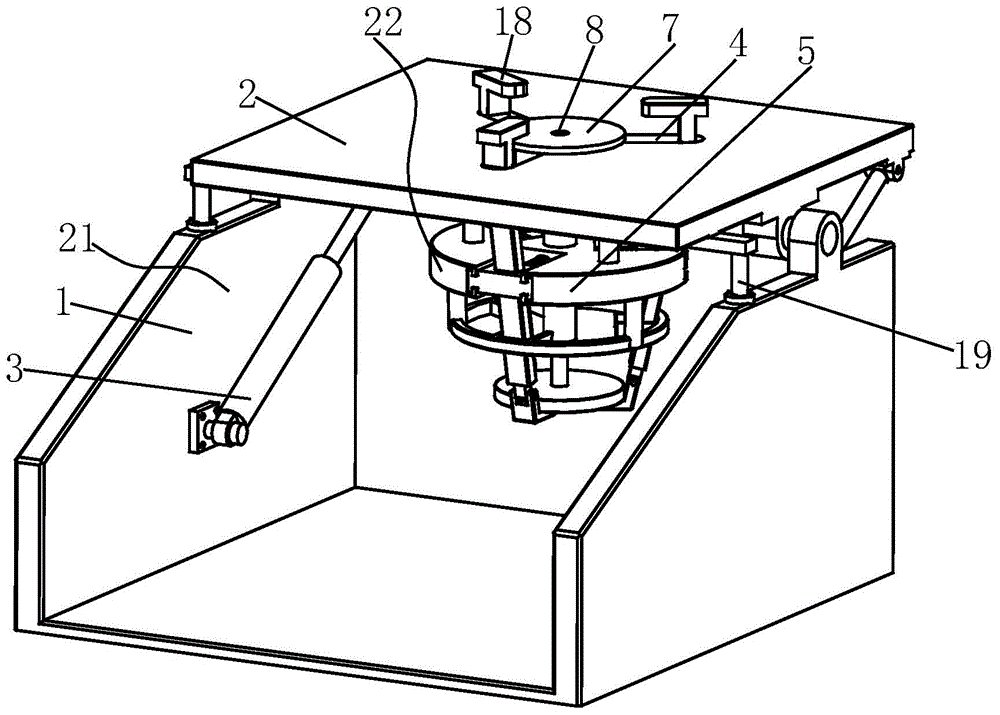

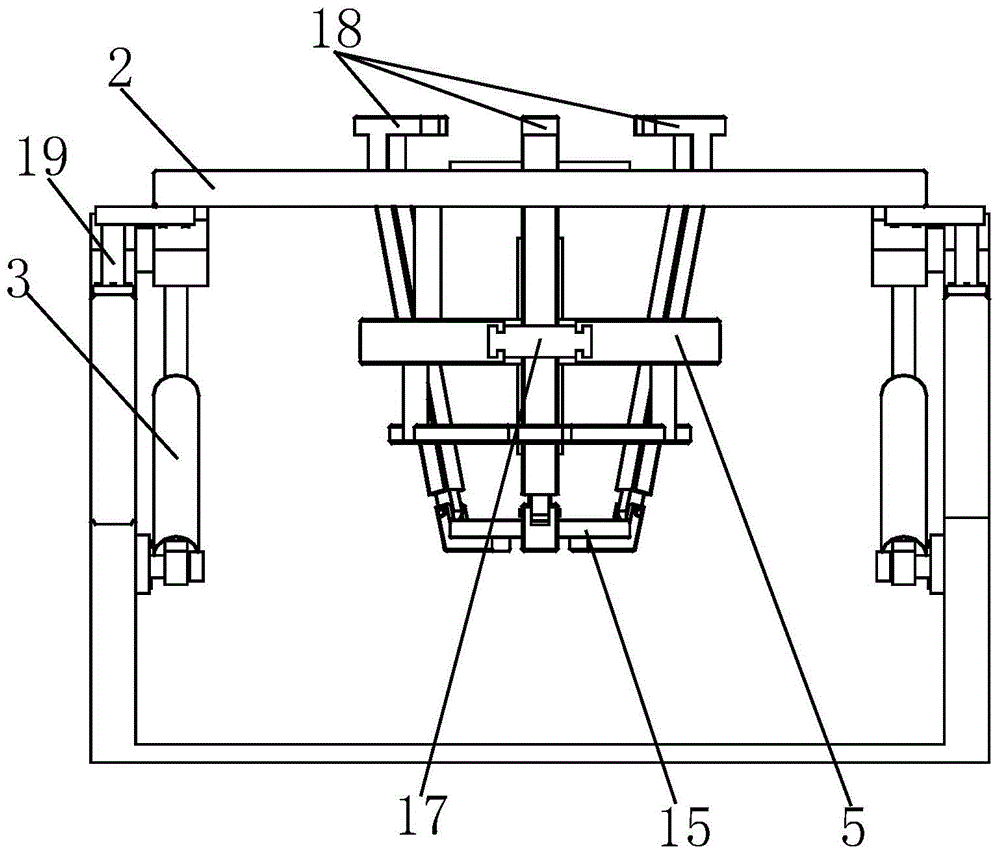

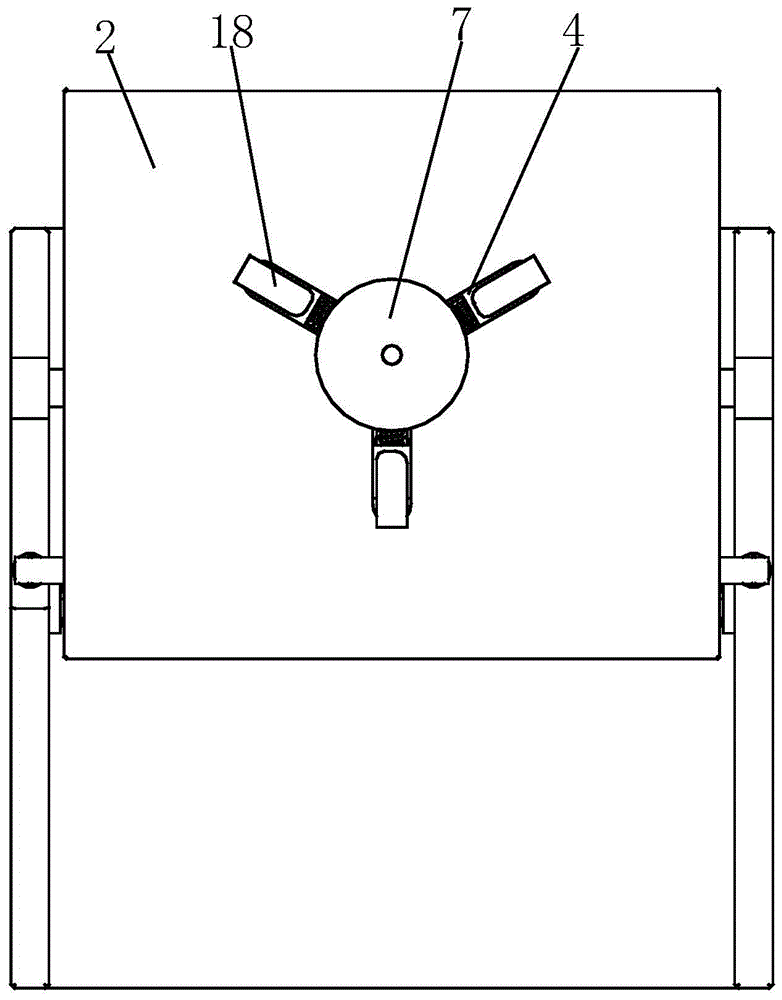

[0026] like Figure 1 to Figure 3 As shown, a single hydraulic cylinder controls a multi-jaw tightness detection chuck for a gate valve, which includes an overturning part 21 and a clamping part 22 .

[0027] The overturning part 21 includes a bearing substrate 1, the upper end of the bearing substrate 1 is hinged with a test platform 2, and an overturning hydraulic cylinder 3 is provided between the bearing substrate 1 and the test platform 2, and a through hole is provided in the middle of the test platform 2. Strip holes 4 are arranged around the through holes.

[0028] like Figure 4 to Figure 10 As shown, the clamping part 22 includes a test bench 2, the lower end of the test bench 2 is fixedly connected with a sub-base plate 5, the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com